We are at a time when companies are looking for a new way to engineer and manufacture products – one defined by the need for smarter decisions, faster feedback, and real-time access to product and business information. For the last few decades, the industry has leaned on traditional PLM tools as a “single source of truth”, which was designed as a central database where everything about a product should “live”. In theory, it made sense. In practice, it didn’t work.

What we got instead were fragmented systems, disconnected teams, and growing silos across the product lifecycle. Engineers designed. Procurement scrambled. Manufacturing struggled to keep up. And somewhere in the middle, decisions were made without the right context or data.

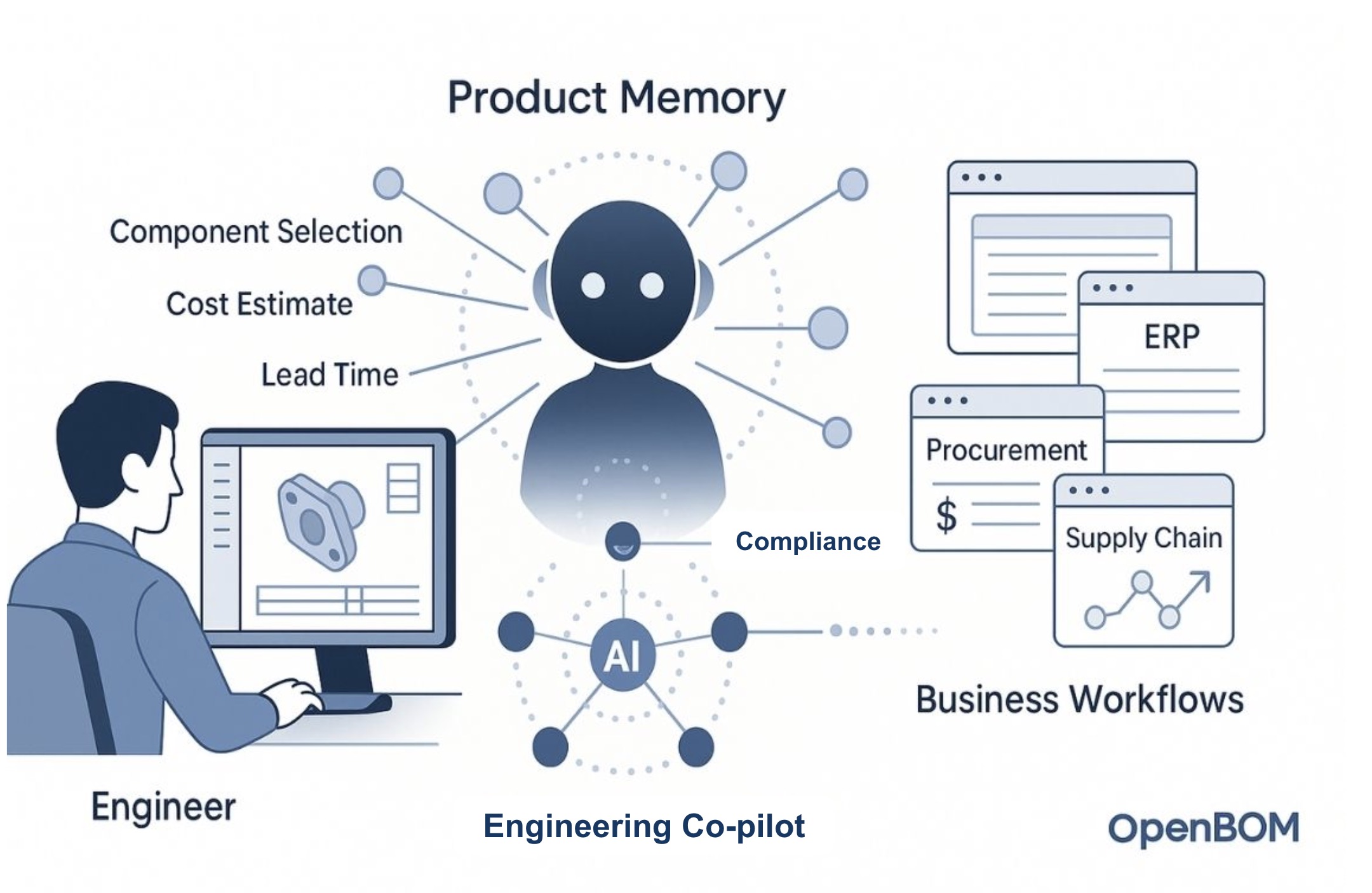

It’s time for a change. At OpenBOM, we believe the future lies at the intersection of engineering co-pilots and “product memory” – a combination that brings together the user experience of AI tools with the structured knowledge of how products are actually built, bought, and delivered.

Let’s unpack this vision.

Why the Old “Single Source of Truth” Approach Didn’t Work

For a long time, a holy grail PLM was framed as a monolithic system that promised to contain all your product data. You’d input your designs, link them to parts and vendors, track changes, route approvals, and magically, everyone from engineering to operations would be aligned.

But here’s the problem: Real engineering and business work doesn’t happen inside one system. It happens across hundreds of tools, spreadsheets, emails, ERPs, and shared drives. People work in silos not because they want to, but because they have to.

Even the most robust PLM systems become just another silo and often remind you of a monstrosity of data and applications. Engineers didn’t use them unless forced to. Procurement couldn’t get what they needed. Manufacturing didn’t trust the data. So instead of a single source of truth, we ended up with fragmented pieces of information, scattered across functions.

The result? Poor decisions, unnecessary mistakes, delays, and friction at every stage.

The Need: Connecting Engineering Work with Business Information

What engineers really need isn’t another form to fill out or another database to maintain. They need access to the right information at the right moment when selecting a component, estimating cost, checking supplier lead time, or understanding a customer requirement.

That information doesn’t live in CAD alone. It’s spread across the entire lifecycle of the product – procurement, inventory, compliance, change orders, support tickets, field service, and more.

Imagine if this information could be brought to engineers naturally, within the context of their design work. Imagine if every decision they made could be supported by insights from across the business.

That’s where the combination of product memory and an engineering co-pilot comes in.

Our Vision: Product Memory + Engineering Co-Pilot

At OpenBOM, we see the future of engineering support in two key elements:

Product Memory

Think of product memory as a dynamic, evolving knowledge base that connects designs, parts, changes, suppliers, costs, orders, issues, and usage history. It’s built using a modern data management foundation with the core flexible product knowledge graph data model – it’s a living memory of everything that’s happened to your product, across every stage of its lifecycle.

OpenBOM captures this by integrating with your design tools, your procurement systems, and your supply chain. It sees how a part was selected, what vendor supplied it, what issues arose in production, and how it performed in the field.

Instead of disconnected snapshots, product memory gives you a linked, contextualized understanding of your product’s lifecycle from concept to retirement.

Engineering Co-Pilot

The engineering co-pilot is an intelligent assistant that sits beside the engineer – not as a replacement, but as a context-aware guide.

It understands the current design. It has access to product memory. And it can help by:

- Suggesting components based on availability, cost, and lead time

- Flagging parts with quality issues or obsolescence risks

- Surfacing related designs and customer use cases

- Highlighting early cost estimates or margin concerns

- Answering common questions like “What supplier is best for this part?” or “Have we used this before?”

This is not a search engine. It’s not a chatbot for the BOM. It’s a co-pilot that is always learning, always ready to help, always contextually aware.

What Makes OpenBOM Different

We’ve built OpenBOM to be more than a BOM tool. It’s a cloud-native platform designed to capture the complete lifecycle of your product, and more importantly, make that information actionable.

We collect and connect information from:

- Design (CAD, revision control, configurations)

- Procurement (vendors, prices, lead times, order history)

- Manufacturing (routing, quantities, suppliers, roll-ups)

- Support and Service (field feedback, part replacement, usage logs)

This structured memory of your product becomes the foundation for the engineering co-pilot.

So when an engineer adds a new capacitor, the co-pilot can instantly say:

“This part has a 22-week lead time from your preferred supplier. Here are three alternatives used in similar assemblies with better availability. Here’s the last purchase price and quality rating. Would you like to add it to the sourcing plan?”

That’s the kind of intelligent, lifecycle-aware support that engineers need.

A New Chapter: OpenBOM AI Agent

We’re calling our new initiative BOM AI—a system designed to harness product lifecycle data and turn it into a powerful resource for engineering co-pilots.

We’re starting with key workflows like:

- Component selection with vendor insight

- Early cost estimation during design

- Sourcing and availability feedback

- Compliance and alternate suggestions

- Integration of customer and usage data

As BOM AI grows, it will support natural interaction, allowing engineers to ask:

- “What’s the cheapest reliable alternative to this part?”

- “Have we used this supplier before?”

- “What does this assembly cost at current volumes?”

- “What design changes caused cost overruns last year?”

- “Which components are at risk for obsolescence?”

The role of OpenBOM BOM AI agent is to provide contextual information to engineering co-pilots and blend this information with other sources of knowledge used by engineers. This isn’t fantasy. It’s already in motion.

Conclusion: From Static Data to Smart Decisions

The old PLM dream of a “single source of truth” was always too narrow. Engineering is too complex, too fast-moving, too interconnected for any one system to do it all.

Instead, the future lies in building smart systems that connect people, data, and context in real time.

At OpenBOM, we believe in:

- Capturing product memory as it happens

- Empowering engineers with AI-driven co-pilots

- Closing the gap between engineering and business workflows

- Helping teams make better decisions, faster

We’re building this future now. And we’d love to hear from you.

What questions do your engineers ask every day?

What decisions could they make better—with the right information?

Let’s talk about how OpenBOM and BOM AI can help your team work smarter.

Interested in being part of the future of Engineering Co-Pilots? Contact us today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.