Contract Manufacturing is becoming a widely used business model in manufacturing. However, it often triggers many questions about managing data and process between organizations. In today’s article, I’m going to share best practices of how to handle Bill of Materials in Contract Manufacturing.

You have most likely heard of terms like EBOMs, MBOMs and so one. However, at which stage of your product’s life cycle do you need to have these BOMs?

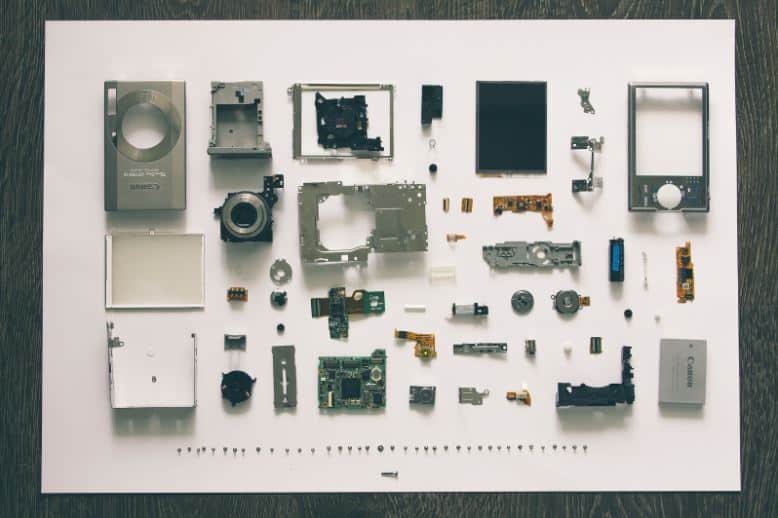

I like to say the manufacturing BOM (MBOM) holds the knowledge of the part you are manufacturing. And at the manufacturing stage, having your BOM as clearly defined as possible will help create a consistent product. But your BOM, similar to your product design, does not become perfect overnight, but goes through multiple versions.

What is BOM Journey?

Let’s understand the journey your BOM will be going through. Usually the BOM’s journey starts off in CAD. This means extracting information from CAD and inputting it in your BOM. You can either do this manually, using OpenBOM’s one click BOM or something else. The BOM that is generated here is called the engineering BOM (EBOM).

EBOM (Engineering BOM)

The EBOM represents what is drawn up in CAD and will be missing some items and specifications. The missing items include adhesives, lubrication, tape and other off the shelf components that usually are used in assembly. You will want to manually add these missing items.

You should also add each mechanical and electronic part that is purchased from suppliers. Think of motors, actuators, etc… These are not customized and can take up just one item on the BOM with a link to the purchasing party with the manufacturing part number (MPN).

There is other information that is not stored in CAD that you will also need to define in the EBOM. You should try to define the following:

- Material – Make sure you are specific with the grade (i.e. aluminum 6061-T6)

- Preferred fabrication method (i.e. die-cast, extrusion, plastic injection molding)

- Finishing (i.e powder coating)

- Color (i.e. pantone #)

- Quantity – how many units of each item is needed (i.e. Four M4x10 screws)

- Part Requirements

- 2D & 3D drawings

Failing to define these specifications before you hand this over to your manufacturing partner will create subjective requirements.

You are now ready to hand over the EBOM to suppliers or your manufacturing partner.

I have found that if the EBOM is clearly defined, all 7 points above are defined, you will have a smooth transition. However, if you fail to define these, expect multiple back and forths with your supplier.

MBOM (Manufacturing BOM)

Your manufacturing partner will be responsible for creating the MBOM. The MBOM is basically the EBOM but on steroids. It will contain all 7 parts from the EBOM and I would also include:

- Standard Operating Procedures (SOP) – steps to fabricating a part and how to assemble a product or sub-assembly

- Standard Inspection Procedures (SIP) – Steps of inspecting the part, sub-assembly and final assembled products.

- Quality Requirements

- Lead Time (you need to have this to manage the project and final assembly)

- And more, depending on the part.

No one expects you to have the MBOM during the Design for Manufacturing (DFM) or development stages of your product. The BOM does evolve and change with your design. However, as you transition to manufacturing, you need to develop your BOM so it’s clearly defined. You should be confident passing your BOM to your procurement or supplier that they can clearly understand your requirements and purchase or fabricate what you need.

OpenBOM creates, manages and shares your EBOM

OpenBOM believes engineering, supply chain and manufacturing teams should be able to seamlessly manage their parts, vendors, bill of materials, purchase orders and change orders. All BOM, engineering and manufacturing information is stored in the cloud which you can share with your team, contractors, suppliers or anyone else that has access to your account. OpenBOM keeps everyone on the same BOM while providing you with the tools to streamline your development to production & scale up operations.

Register for FREE to create your OpenBOM account and reach out to us via support@openbom.com if you have any questions.

Regards, Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.