The way of manufacturing is changing and transforming day by day. Digital transformation is reshaping what is possible and how companies are able to become more agile and efficient.

Some of these transformations are new innovative business models and technologies that help manufacturing organizations achieve digital excellence.

Graph Theory and Graph Databases

Technology transformation can do some magical things and today I’m going to talk about one of the technologies OpenBOM is developing by relying on the power of graph databases and analytics.

What makes us super excited about OpenBOM is the ability to apply the network perspective on the analysis of bill of materials.

In a nutshell, we are working on graph theory to analyze the bill of materials of multiple products in a way that can provide huge improvements and recommendations to manufacturing companies on how to optimize their BOMs.

Think about the way to discover a potential impact of specific component and supplier selections on the outcome of the BOM – the product company builds.

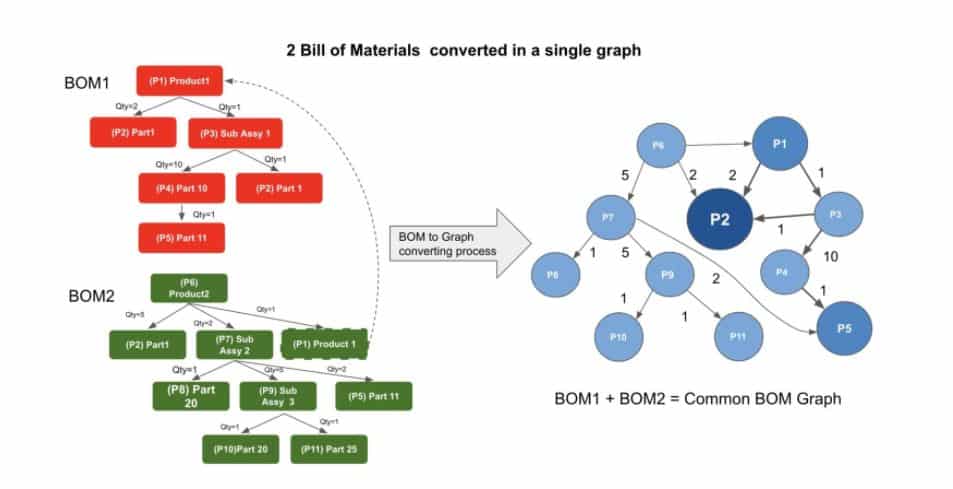

The key idea is aggregation of multiple BOMs using graph structure sharing the same components. In such a case the complexity of analyzes is increasing with the increasing complexity of the product and multiplication of parts.

Analyzing critical nodes in the graph, which is built for multiple bills of materials, can give you very interesting impact analyzes. The key element in the analysis is a part number for materials, assemblies and sub-assemblies. The in-degree value in a graph points out the number of finished parts that use the part. The latter can be taken in the account when analyzing the impact on product planning.

Multiple Products In One Graph

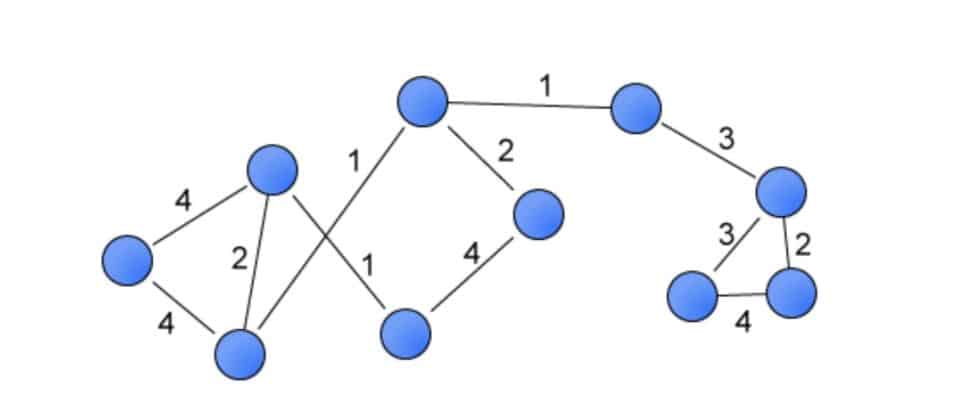

The first step towards BOM intelligence is to transform the Bill of Materials data into a weighted graph. Such a graph can be a very interesting object as it can represent many things in a bill of materials, such as quantity or part usage in other assemblies.

Now, let’s think about what will happen if we bring multiple BOMs and combine them together in a single graph. We will use the same principle of combining some information such as frequency of the node (part usage) and also will use the thickness of the edge to express the number of products (BOM) a specific part is used.

OpenBOM creates a graph representation of all Bill of Materials in the OpenBOM platform by applying graph technology and graph databases. Each time a user is creating bill of materials, a corresponding graph model is created and it allows OpenBOM to provide basic operations on the Bill of Materials (eg. Where used queries).

But it is just the first step of the graph and network utilization. Advanced analysis of the Common BOM graph can provide an insight into the dependencies between supplies, contractors, vendors, component usage and many others.Product Intelligence

The set of algorithms about clustering can bring an interesting perspective on connectedness between products and their parts. By analyzing the connections between parts, we can identify common groups (clusters) and the common graph between two products, which can help us to build a sense of dependencies and commonalities between products. Totally disconnected graphs and opposite to that – no clusters can help us to get an interesting insight into the product, components, suppliers, and their dependencies. We can drive a conclusion about similar attributes and grouping of nodes.

Clustering and other topological analysis will help us to drive the conclusion about how product structure (and their dependencies) can be integrated or disintegrated, which will lead us towards decision-making about risks in inventory planning, supply chain, maintenance parts, and many other aspects.

Read more here – OpenBOM: Graphs, Networks, and Bill of Materials

Conclusion

Product intelligence is the name of the game these days. How to glean the intelligence from the product data? This is one of the goals we are very excited about here at OpenBOM.

Manufacturing companies are sitting on a goldmine of product information, but cannot use it because the data is locked in multiple legacy databases, files and also siloed between multiple companies, contractors and suppliers.

The Bill of Materials is the lifeblood of every manufacturing business. Knowing how to optimize a bill of materials can provide huge benefits. We are excited to stay on the course of applying data science to product structures and bill of materials as we continue to build OpenBOM.

In the near future, data-driven manufacturing companies will succeed because they will be able to bring intelligence to the product development game.

Want to discuss how to make BOMs more intelligent? Please reach out to me via email at Oleg @ openbom dot com

Register for FREE at OpenBOM and take your first steps in building BOM intelligence for your business.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.