It’s the 21st century and data has become the new oil. Companies of all types and sizes are hunting for data because it is the only way in the modern manufacturing environment to become agile and efficient, to move from selling products to selling services, and to innovate outside of a single building and a single silo.

Unfortunately, for many companies, Excel spreadsheets and multiple databases and files are the ugly reality. Companies are struggling to get data captured easily and flexibly, experience significant difficulties in sharing the information even in the same company, and send tons of emails with attached spreadsheets from engineering downstream to communicate tasks and run processes such as product planning and procurement.

What Is Digital Thread?

You probably heard about the new magic word in enterprise, engineering, and manufacturing software – Digital Thread. The concept of Digital Thread is not new and its goal is to build a connected set of data across multiple departments, companies, and silos of information.

Digital Thread is the key to achieve product information traceability, allowing to track a product and related product information such as files, specifications, manufacturing, contractors, and suppliers data.

Digital Thread is a foundation that helps you organize a seamless flow of information and get the right data in front of the right people to make a decision. Digital Thread is the foundation needed to build a collaborative solution that helps connect your team, contractors, and suppliers, making communication that much easier.

In reality, the digital thread is not a magic solution to solve all your problems, but more an approach to improve the process of data management, communication, and data sharing.

It can also be different depending on the type of digital thread you need to build. In a manufacturing company, for example, you can think about building a production digital thread connecting engineering and business activities in a single process. You can build a maintenance digital thread to focus on the process of maintenance of products and services. There are other options as well.

From Integrations To Digital Thread

In the past, data integration was used as an approach to connect multiple systems. There are a variety of technologies used to create integrations from point-to-point solutions to advanced systems using enterprise application integration platforms, enterprise service bus, and many others. Modern cloud technologies provide a much better way to connect information, people, and processes together through – data management flexibility, global accessibility, and flexible new data services API which allow for easier and faster information.

The key achievement of Digital Thread is to ensure a seamless information flow. The end game of Digital Thread is to establish access to the information for everyone in the company and also outside with contractors and suppliers. The data should not be locked in files only accessible through desktop computers and legacy databases.

So, if you are thinking about Digital Thread for dummies, you need to figure out how to have the data from multiple tools and repositories to be connected and traceable. The idea is simple, but the realization is not that simple in most cases. The main reason – the integrations are complex and the data platforms are complex, not flexible enough, and run in a single database with no global availability. Pushing data from one place to another can give you a “pipe” at best, but not the thread.

3 Steps OpenBOM Can Help You To Start A Digital Thread

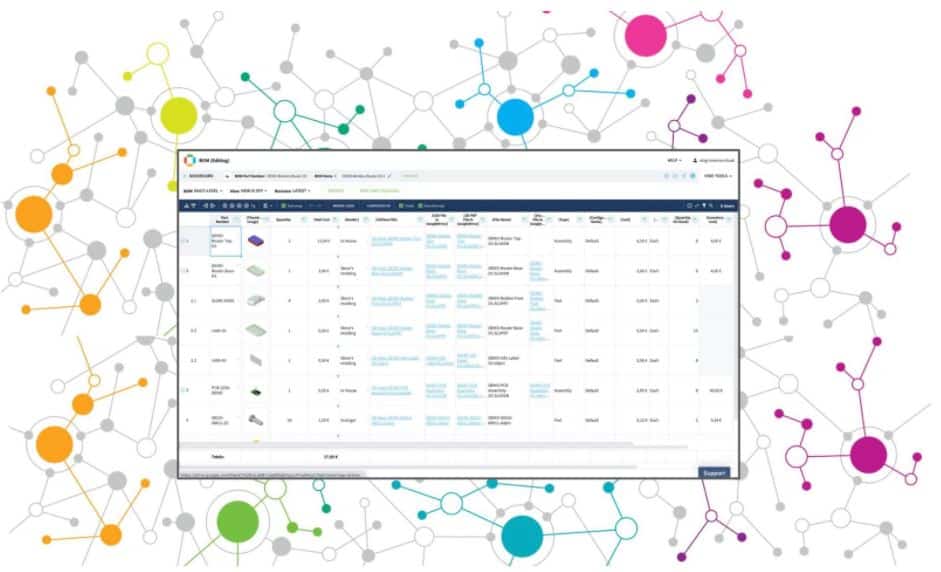

At OpenBOM, we’ve been thinking about digital thread from the very beginning. OpenBOM’s vision of capturing information easily from different data sources and systems has come true. Our platform allows for the creation of product data representation with a flexible data model including all properties needed and organizing seamless global data access to everyone who needs access to the data using OpenBOM multi-tenant data platform and instant data sharing and collaboration mechanism.

So, how to start with OpenBOM easily?

Step 1 – Identify data sources

This is the planning stage. You need to identify data sources in your company. They can be legacy databases, Excel spreadsheets, CAD systems, PDM, PLM, or ERP systems. For many companies we work with, Excel spreadsheets are the brutal reality of data management. Combined with CAD systems they create a mess of data that cannot be easily managed.

Step 2 – Setup Integrations, Add-ins or use REST API

OpenBOM provides many integrations to a variety of systems. There are many out of the box integrations that can be used right away and help you bring the data you need immediately. For these systems, you need to download and set up the integration and you can find recommendations on how to do it in our Training Library.

OpenBOM can also provide custom integration and integrate with a variety of legacy data sources you might have, In addition to that, OpenBOM REST API gives you the ability to connect with other online systems and develop your own custom integrations and data extraction processes.

Step 3 – Add People and Configure Data Sharing

Once you have the data in OpenBOM, you can plan how to share the information with your internal and extended team. OpenBOM company and team subscriptions allow you to add people and organizations instantly and configure data sharing mechanisms that will give access to the data in the right format and limit access to data that is not needed.

Conclusion

OpenBOM gives you an easy way to start managing the information about the product you develop and manufacture, while simultaneously connecting contractors and suppliers.

Our platform helps organize a seamless data flow between systems and people in a way where everyone will be able to make an informed decision about what part/assembly needs to be manufactured and what components need to be ordered.

OpenBOM Design to Purchase process is a foundation of seamless process management, while a flexible data model is a way to include all data and link it to all information data sources – CAD systems, databases, Excel files, and others. OpenBOM data platform manages all information including files, links, and references to other systems. A seamless REST API allows you to connect any other data system and out-of-the-box spreadsheet import allows you to bring any legacy data you might have.

Check out OpenBOM today. Register for FREE and start a free 14-days trial to explore OpenBOM.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.