Modern manufacturing requires streamlining product information management and the application of efficient and robust cost and ordering processes. Cost calculation is critical with supply chain turbulence. RFQ and the purchasing process is a complementary process that requires easy calculation of how many materials or how many pieces of standard parts need to be ordered. To streamline these processes is extremely important.

In my article today, we explore how OpenBOM can help you to manage the calculations with different unit of measures. Here is the model where we want to “end” with an example. This is a project in which for testing purposes we use one wooden sheet and also OTS screws used together.

The Complexity – Different Unit of Measure

Here is the root cause of the problem – different units of measure are used for components and materials for the Bill of Materials and for ordering. For example, you might be able to count single screws for the purpose of BOM and item management. But at the same time, the company will be buying these screws in “boxes”. Similar can be for different materials (eg. wood sheets). While you’re buying it using pieces, the main challenge for seamless cost and ordering calculation, for the Bill of Materials, it will be used via “squared inches”.

OpenBOM can help you here. The complexity of hierarchical relationships and the ability to apply these formulas to the structure, provide a much easier and better approach to perform the calculations.

While you might be familiar with OpenBOM formulas (101) and you can set up a cost, unit of measure, and formulas. In my article today. I will show you how you can set this up for different UOM.

Data Model for Catalog Items with UOM

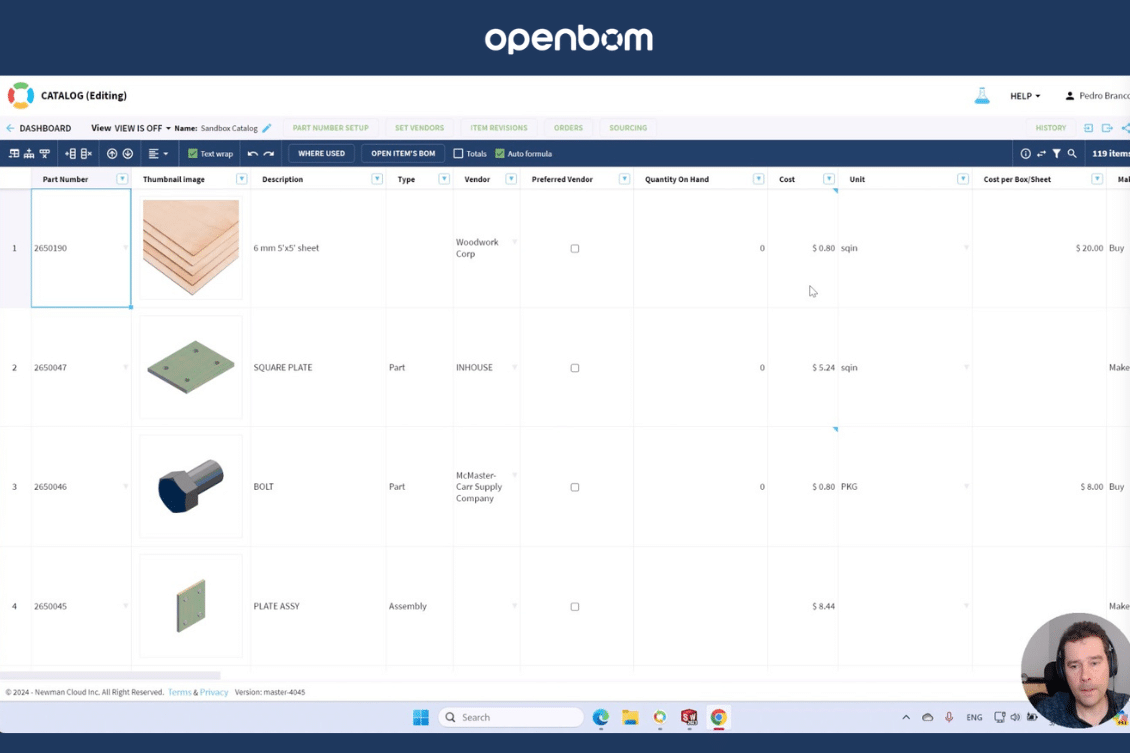

As you can see from the image above, the data model for different Unit of Measure is super simple and allows you to normalize all item types in the catalog to the same value of “Cost”, but use different calculations. You can do it in a single catalog or you can define multiple catalogs for simplicity. The main goal is to have the “Cost” property in a catalog to be calculated depending on other parameters.

Here is an example of the catalog with formulas defined to calculate separately wooden ships and number of screws.

Cost Calculation

The fundamentals of cost calculation are in the dynamic combination of cost calculated in the item (catalog row) combined with the generic cost rollup formula (Extended Cost = Cost x Quantity)

In the picture below, you can see the cost calculation for each square inch of the wooden sheet. Once we get the generic cost, we can use it to calculate the BOM cost.

Once the total cost is calculated, you can see it visible in the right places.

RFQ, Orders, and PO

Once you get cost calculation under control, the next immediate question is how to calculate the right quantities for purchasing. For this purpose, OpenBOM can create an Order (based on components or an entire BOM) and then manage inventory with orders. The quantity values in the Order are using BOM unit of measure that need to be translated to packaging UoM.

Here is the screenshot demonstrating how the catalog with two different structures to manage cost UOM can be managed together.

Demo Video

Watch the video with step-by-step instructions on how to set up formulas for items with different UOM.

Conclusion

To perform BOM cost calculations using Excel is nearly impossible. OpenBOM provides a flexible mechanism to define formulas and adapt them to a specific use case. OpenBOM provides a robust infrastructure to manage product structure (BOM) with the capability to perform rollups in a flexible way, including separate formulas for unit cost calculation dependent on specific parameters. Combined with the Order/RFQ mechanism, these capabilities of calculating cost and the amount of materials/ parts that need to be ordered is an absolute winner to make this process easy, simple, and fast. The time is saved and companies can streamline the ordering process.

REGISTER FOR FREE and check how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.