Excel spreadsheets are a mainstay in most industries, and for good reason – they’re versatile and easy to use. However, when it comes to managing your product information and Bill of Materials (BOM), relying on this single software can lead to some major pitfalls.

In our daily practice at OpenBOM, we meet thousands of engineers and companies coming to us with a single question – how can we improve data and process management? This simple question usually leads to a fundamental decision – every manufacturing company must have a data management strategy. Such analysis will inevitably take you to the point where you ask the question – what is the cost of “free Excel”? In this post, we take a look at the real cost of free excel BOM management and explore some of the better alternatives out there.

Point to Point Data Strategy Weakness

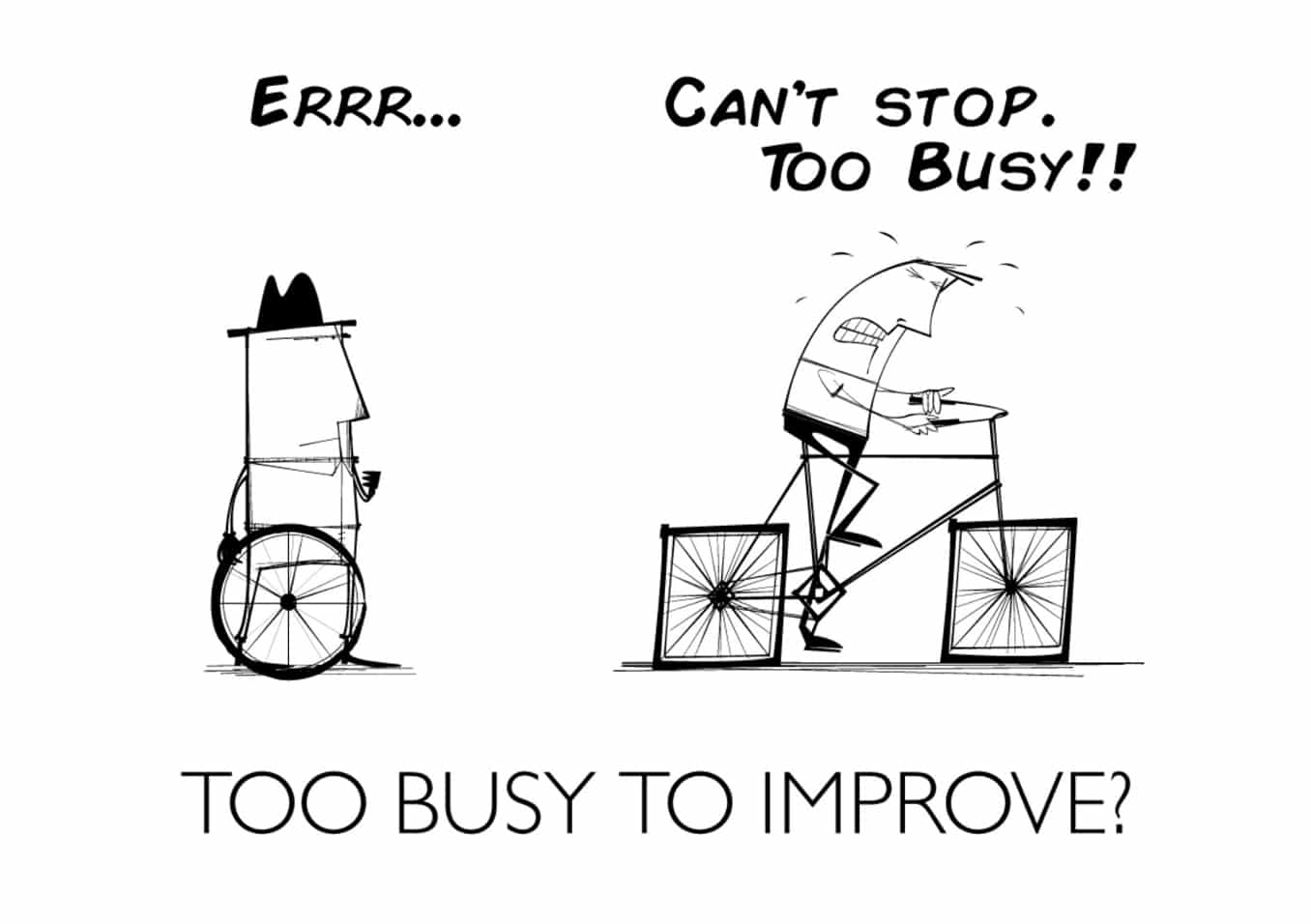

Silos in thinking is a killer of any holistic data strategy. Every organization, even a very small one is represented by a siloed structure with an organization and people focusing on their jobs. It can be engineering, procurement, or manufacturing planning. While everyone is thinking about how to improve his/her work (better design, optimal planning, better suppliers), typically no one in the organization is thinking about how to improve the information flow. It is getting lost and no one is thinking about what will happen with the data and communication moving between silos.

An easy and quick way of looking at it is as a batch process of data transfers – sending CAD drawings, reporting orders, and sending RFQs and POs. This is just a small number of examples. While each person (or department) in this siloed organization thinks about their own job, very little thought is applied to all these information flows. Until it is a mess…

The situation repeats from company to company. I was talking to the people that were in charge of making such decisions. A simple question – why did you decide to use Excel and email? The shocking answer is “because it is FREE”.

The root cause of the problem is not thinking about information flow and instead thinking about how to optimize the work of each silo – do a better design, optimal planning, and other tasks. What is missed here is that bad information flow has its impact and cost.

Let’s talk about them…

3 Pitfalls of Excel Data Management

There are many implications of spreadsheets used for data management. Each conversation coming from siloed email/spreadsheet can be slightly different and you might be confused. You can hear it as questions like “how do I get data updated in Excel?” or “how do I find what to change?” or ” where is the last revision?”. Although many of these questions are just examples of inefficiency, there are 3 fundamental traps you will be getting into when using spreadsheets.

- A single source of truth

- Eary visibility

- Dependencies

Let me explain each of them and what problems they can cause to your organization.

A single source of truth (SSOT)

Not having a single place where information about your product is saved is a big problem. You cannot manage something that doesn’t have a unified representation. Multiple spreadsheets are flying around the organization and each of them has an important purpose. But when you’re trying to find the right piece of information, you cannot do it. Even more, you are getting multiple nuggets of data you cannot combine together. The result of this “free” solution is that you’re making decisions based on the wrong information – forgetting components, buying wrong parts, making wrong cost estimations, etc. All these bad decisions have a direct financial impact.

Early Data Visibility

It is crucial to make information available across the organization. What can be better than providing early visibility on the BOM for procurement and sharing information with product planners? It can be great to make an assessment of the regulation and compliance risks and get timely quotes from contractors. All these can be possible if data is available and shared. In the absence of this mechanism, each silo holds the data until the very last moment to minimize the risk of data transmission and data losses. Result – information is not available on time. It cost the organization a lot of money in wrong orders, delayed deliveries, the absence of certifications, and many others.

Data Dependencies

Everything is connected in a modern product lifecycle management, development, and manufacturing. Mechanical, electronic, and software components. Suppliers and contractors. Customers and their productions combined with maintenance. While dependencies are the nature of the business, Excels (and spreadsheets) are not connected. And this is where the problem usually starts. Product structure, references to CAD design, revisions, RFQs, and POs… Lost connections between pieces of information lead to making wrong decisions and, as a result, missing dates, costs, absence of certifications, etc.

How to escape Excel Hell

Once you realize the real cost of free Excel BOM management, the next step is to decide how to fix it. My recommendation is to go in steps: (1) Data assessment; (2) Data Platform; (3) Integrations; (4) Legacy Data import; (5) Repeat 1-4 again. Let me speak about each of these steps.

- Check what you have. Make an analysis of your current data assets. What do you have? Where is it stored? How to clean the data? Who is using it?

- Decide on the data platform you will be using. Check data management capabilities, flexibility, adaptation, and scale. Don’t rush – choosing the right platform is an important step. Also, my recommendation is to focus on “openness” because it will allow the integration of multiple solutions together.

- Each time data is manually copied, you have the potential to make a mistake. So, focus on automation and how to easily transfer data between applications.

- Decide what data to import and exclude. Sometimes, changes is a great time to clean the old stuff you don’t need.

Most importantly, is to go with steps and don’t try to boil the ocean. Agile small steps will allow you to create the right strategy and bring value to the organization.

Conclusion

Data management is a foundation of digital businesses. Every engineering and manufacturing company these days is looking at how to transform its processes and become a digital entity. The value of Digital BOM is tremendous and the cost of free Excel is beyond what modern manufacturing companies can afford to pay.

REGISTER FOR FREE and check out how OpenBOM can help you today.

Best, Oleg

Image credit – Alan O’Rourke from Ireland, CC BY 2.0 via Wikimedia Commons

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.