The digital transformation in industries across the globe has necessitated a shift towards more integrated, efficient, and accurate solutions. In an increasingly competitive and fast-paced market environment, it is crucial for all manufacturing companies of all sizes to stay ahead. The way products are developed, from initial design to final procurement, is pivotal to the growth and success of these organizations. A well-structured New Product Development (NPD) process can substantially contribute to productivity and overall efficiency.

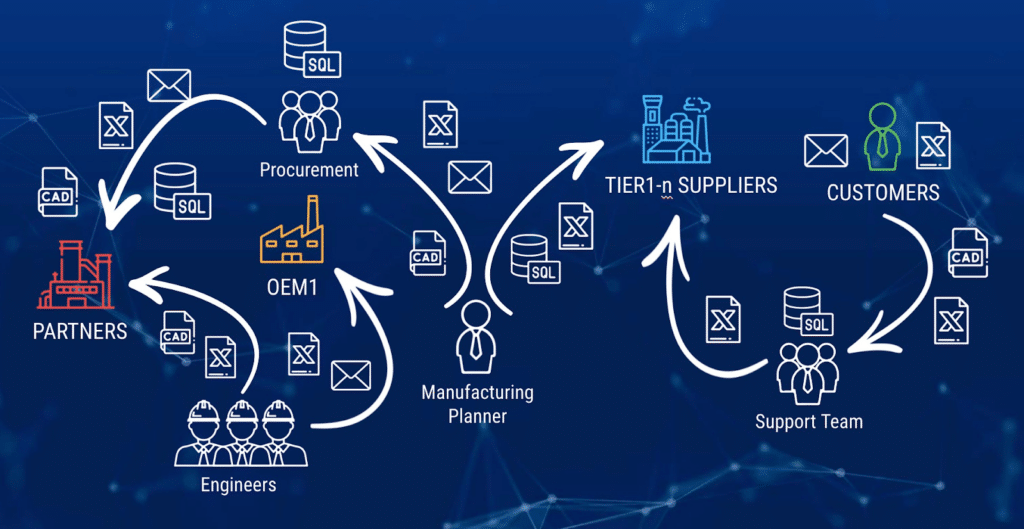

From the first days of OpenBOM, we’ve been talking to many small and medium-sized manufacturing companies, engineering teams, and NPD departments of large enterprises, digging into the nuts and bolts of NPD processes. What was common for all these teams and companies is a huge disconnect between people and different functions – engineering and procurement. Think about the following picture.

As you can see, the process is flowing between multiple teams and companies and it is very fragmented. Which makes it really painful. Think about two teams – (1) engineering and (2) procurement and how they need together. I was talking about it in my article – Need for Speed and Digital Thread Between Engineering and Procurement Processes. The main problem of these teams is an extreme inefficiency of data management and communication. Engineers are responsible for the design and use Excel export to communicate their needs to procurement. On the other side, procurement works with inventory and suppliers to source components but doesn’t control the engineering BOM and related information. It is a mess, which leads to delays, increased costs, and bad quality. It is a big problem.

5 Elements of OpenBOM NPD Solution

OpenBOM is a digital thread platform that helps to solve the problems I described above. With its comprehensive suite of capabilities designed to streamline engineering and procurement functions, OpenBOM stands out as a reliable solution for SMB, SME, and new product development teams at enterprise companies. Let’s dive into the five crucial elements that define OpenBOM’s unique value proposition:

- Excel Replacement: Traditionally, industries have heavily relied on Excel for managing their product data, which often leads to numerous inconsistencies and inaccuracies. OpenBOM’s NPD solution takes Excel out of the equation. It replaces Excel, providing an intuitive data management platform that manages engineering, inventory, and procurement data. It removes the risk of human error associated with manual entries. It simplifies data entry, tracking, and reporting, ensuring more accurate and consistent data for all stakeholders.

- Integration with Computer-Aided Design (CAD): To further augment the product development process, OpenBOM seamlessly integrates with numerous CAD systems. It enables a real-time view of design changes, ensuring that everyone involved in the project has the most recent data. One-click BOM function allows to the extraction of BOM information and all related files, automatically creating derivatives such as PDF, STEP, STL, DXF, and other files needed for RFQ and sourcing. This synchronization reduces discrepancies between engineering and procurement teams and shortens the time to market.

- Product Lifecycle and Single Source of Truth: OpenBOM brings together data from engineering, procurement, customer, and other places organizing a single source of truth for all product data. By centralizing all product information, it allows different teams – from design to procurement – to access the same, accurate data. It reduces instances of outdated data or conflicting versions, ensuring the most updated information is always available for every team member.

- Bill of Materials (BOM) Management and Analysis: OpenBOM’s comprehensive BOM management system is pivotal in managing complex product structures. It supports features such as cost rollup, which gives a comprehensive view of the total product cost by adding up all the component costs. By capturing all engineering data, OpenBOM offers a powerful tool for analyzing BOMs, enabling better decision-making and more cost-efficient strategies.

- Inventory Management and Request for Quotation (RFQ)/Procurement Process: OpenBOM’s NPD solution goes beyond design and engineering by incorporating inventory management and RFQ/Procurement functions. It provides real-time inventory data, reducing the risk of stock-outs or overstocking. The RFQ module makes the procurement process more manageable, creating an efficient flow from requisition to purchase order.

OpenBOM NPD Flow

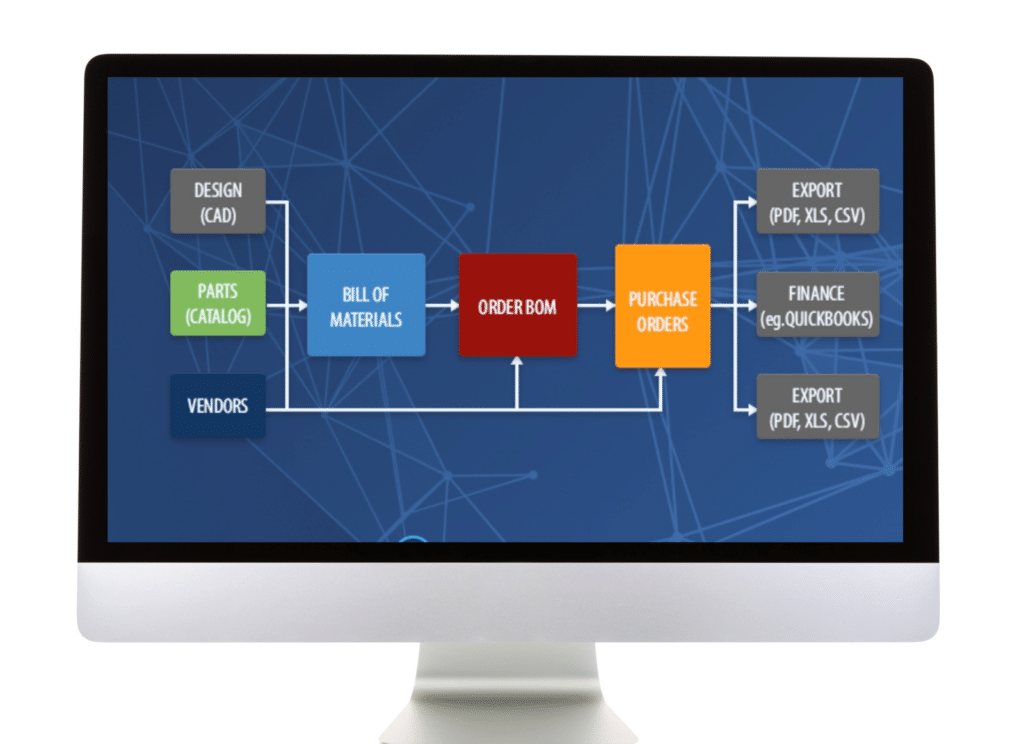

The following diagram shows how OpenBOM business processes work from CAD design to engineering BOM and later to purchase orders and Inventory control. A unique element of the solution is the seamless integration and simplicity of inventory and purchasing functions.

Production planning includes the following mechanism:

- Inventory management (organized via “Catalog Quantity on Hand”)

- Vendor management (allows you to manage lists of vendors and suppliers)

- Order management (order BOM – to manage MBOM for purchase planning)

- Purchase orders (creation and receive)

- Release to the production process to consume components and update inventory levels

Conclusion:

New Product Development using OpenBOM is a comprehensive solution that combines multi-disciplinary functions needed to manage CAD information, extract engineering data, manage BOM, make cost analysis based on sourcing information, plan production batch, estimate inventory gaps, generate RFQ/PO, track received process. It weaves a digital thread linking the engineering and procurement functions, making the product development process faster and more efficient. This integration ensures better products are delivered, while also reducing costs. With its potent suite of features, OpenBOM’s NPD solution is a game-changer, making it an indispensable tool in the ever-evolving landscape of industrial digitization.

REGISTER FOR FREE and check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.