I’m continuing to preview OpenBOM for Onshape enhancements coming very soon for all Onshape customers. If you missed my earlier blog with the demo, please check this out.

OpenBOM For Onshape Enhancements

The key element of OpenBOM for Onshape is to make a completely integrated experience for engineers and everyone else involved in the process of design, engineering, production, and procurement.

OpenBOM for Onshape enhancements will include three groups of new functions:

- Advanced Item Management

- Automatic Part Number Generation

- Support for Onshape versions and release process.

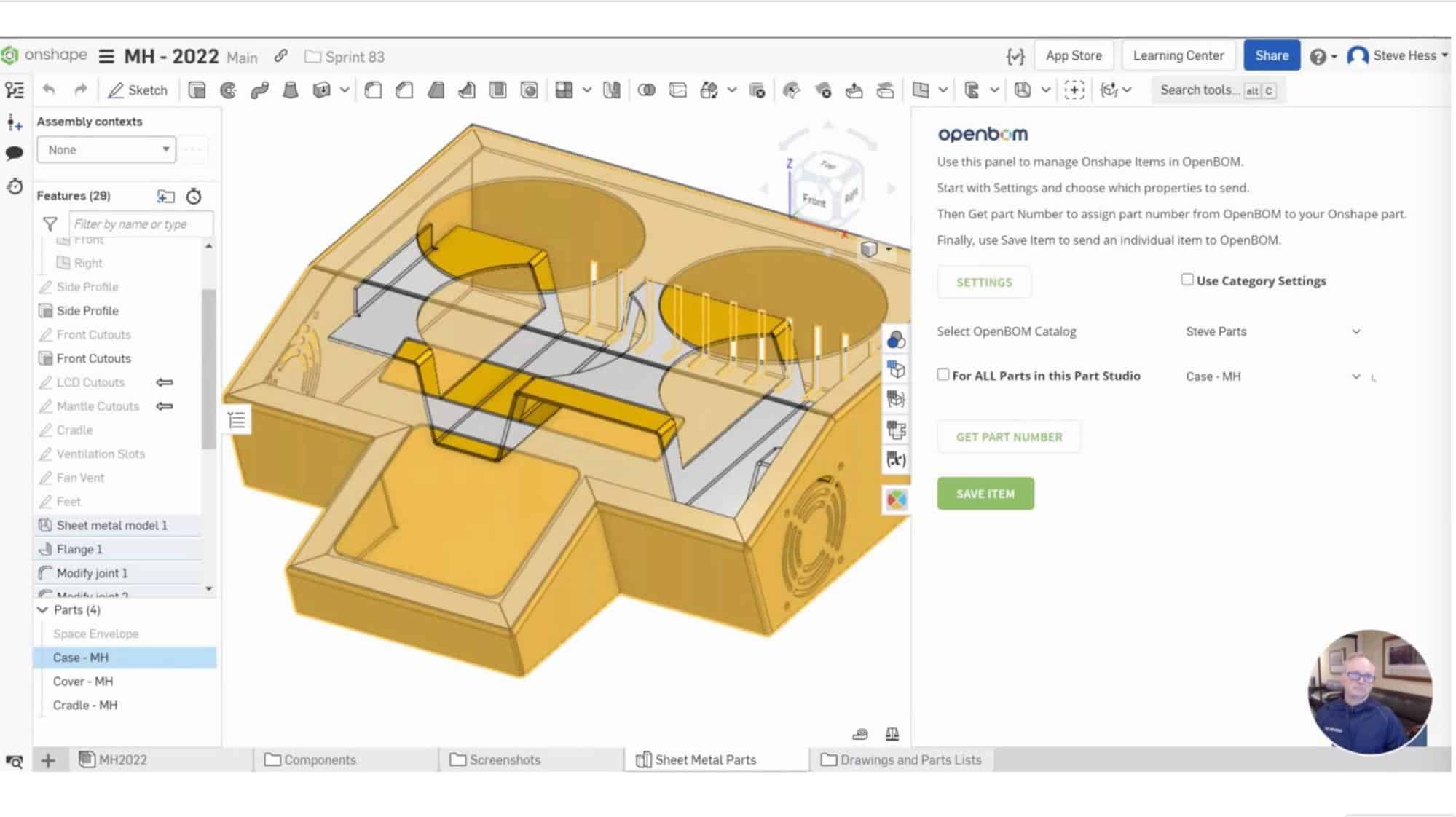

In my previous article, we demonstrated a new automatic part numbering mechanism for Onshape, including a new OpenBOM Item flyout, which will be available in both Onshape Part Studio and Assembly objects.

Item Management in OpenBOM

An item is a key object in the OpenBOM data model. You can create multiple item types in OpenBOM using flexible data modeling and catalog mechanism. The same catalog mechanism includes an automatic Part Number generation process that is used in all CAD integrations.

Using the OpenBOM data model you can define items for everything – mechanical part, standard component, electronic part, assembly, end product. It is universal and you can define any attributes that will be saved in OpenBOM Item with a specific Part Number.

Save Item Command (and Item flyout)

How many times do you want to save a single item (from Assembly or Part) in Onshape without updating an entire assembly? There are many use cases for that. Here are some examples:

- To create an item for a custom part that must be ordered early before a BOM is created.

- Update a specific item in BOM without saving an entire BOM (time-consuming).

There are some other examples as well. I’m super excited to preview a new Save Item command available in the new Item flyout. Check out the video below for more information.

Conclusion

OpenBOM is coming with many enhancements in Onshape integration introducing new integrated behavior for item management, part number generation, and release management process. It includes a completely new OpenBOM Item Flyout as well as support for new functions. Save Item is one of them, which allows you to optimize the process of data handover from Onshape to OpenBOM and later downstream processes – cost estimation, procurement, and many others.

If you’re using OpenBOM with Onshape or looking for better support of Onshape based product development, reach out to us and we would be happy to include you in the list of first beta customers to experiment with new OpenBOM for Onshape processes.

In the meantime, REGISTER FOR FREE to check out how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.