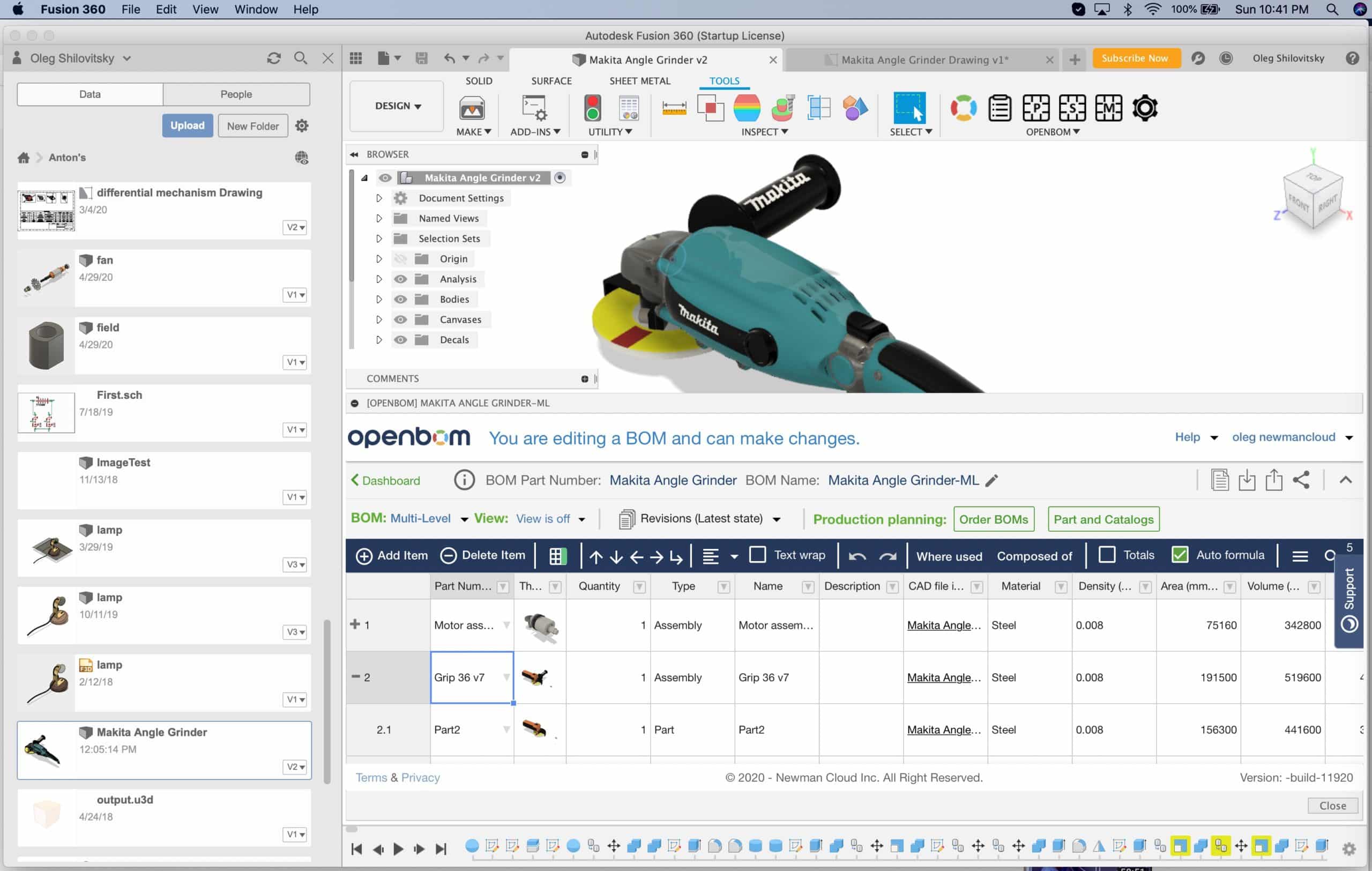

A few weeks ago we announced support for Autodesk Fusion360 native table features. If you missed my earlier blog, please check it here – OpenBOM Native Drawing Support For Fusion360. And today, I’m coming again with a piece of early information about new features in OpenBOM for Autodesk Fusion 360.

We’ve been working with many Fusion 360 customers and users and we found these two features absolutely necessary to improve the efficiency of BOM creation and flexibility of design data management.

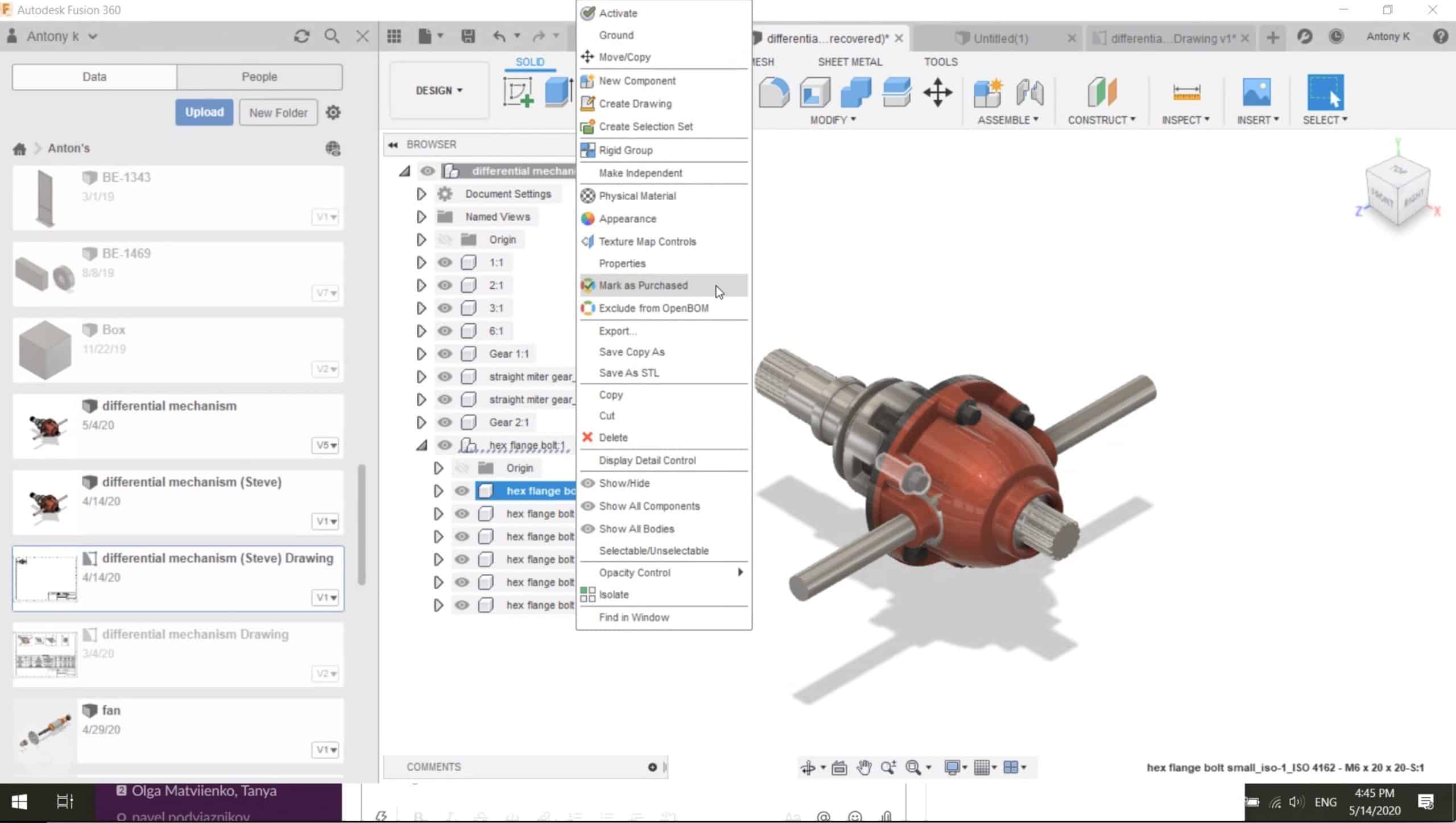

Exclude from BOM

This option is needed when you need to simply exclude one of the components from BOM. It is simple and powerful. Sometimes, you use the component only for specific needs in the design and you don’t want it to show up in the BOM. Just check this option.

Purchased Assembly

Very often, some of the assemblies you use are purchases as a whole pice. Examples – bearings, caster wheels, electrical motors, etc. But at the same time, you need these components to show up in the design with all parts. By marking components as a purchased assembly in OpenBOM you will be able to keep the geometry in Fusion 360, but exclude it from the BOM.

Conclusion

Very powerful and useful options for all Autodesk Fusion 360 users will allow flexible options to define what components are exported to OpenBOM and what components preserved only in Fusion 360 design. Soon will become available for all users. Meantime stay tuned. If you want to test these options before the release, please let us know and contact OpenBOM support.

Check OpenBOM now by registering an account here.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.