There is no person in the world that wake up in the morning and says – I need to buy a software. The same can be said about businesses – engineering team, manufacturing company, contractors, suppliers – all of them start from the problem they need to solve. Therefore, the tools we use matter—but only if they drive real results.

There is no lack for technology marketing these days – SaaS, Cloud, Big Data, Low Code, AI… you name it. When it comes to selecting a software for engineering or manufacturing such, PDM, PLM, MRP, ERP, most companies face the same core dilemma: how do you separate modern marketing buzzwords from actual business impact?

Every vendor talks about cloud, integrations, automation, AI, and collaboration. But let’s be honest—your team isn’t looking for more tech. You’re looking for a way to stop wasting time in spreadsheets, avoid painful mistakes, and build products faster with less friction.

The truth? Customers don’t buy software. They buy solutions to problems.

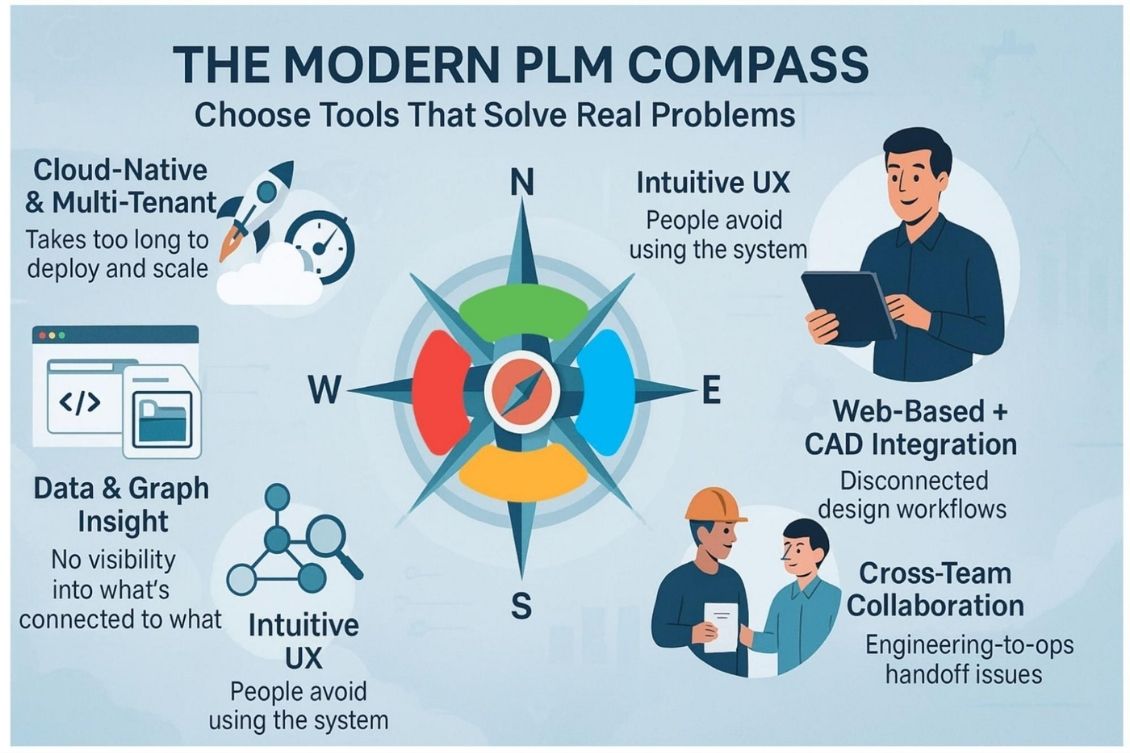

In this post, I will explore how to choose a modern PLM/BOM platform—not just based on its tech architecture, but on how it helps your team perform. We recently set together with one of our customer – NVTS Global, a leading defense technology company, is using OpenBOM to do exactly that.

Check 5 elements of the modern PLM stack and how they are directly connected to solving customer problems.

✅ 1. Cloud-Native and Multi-Tenant: Instant On, Always Available

Let’s start with infrastructure. A modern PLM system needs to be:

- Up and running in minutes, not months

- Managed entirely in the cloud, without IT overhead

- Continuously updated and always improving

That’s the cloud-native, multi-tenant advantage—the opposite of the heavyweight, on-premise systems that dominated PLM for decades.

For NVTS Global, this meant fast deployment and immediate value.

“OpenBOM serves as our PLM repository & system of record for all new and existing designs.”

— Greg Klein, Engineering Production Manager, NVTS Global

Instead of waiting for internal infrastructure or lengthy consulting setups, NVTS engineers were able to centralize and manage their product data right away—without the need for expensive servers, VPN access, or rigid IT timelines.

✅ 2. Web-Native, Yet Seamlessly Connected to Engineering Tools

“Web-based” used to mean “detached” from the real work. Not anymore.

Modern PLM tools should live in the cloud and connect natively to the tools your engineers already use—Dassault Systemes SOLIDWORKS, Autodesk, Altium, PTC Onshape, and others. This is not a luxury; it’s a real need.

At NVTS, the SOLIDWORKS integration is central to their workflow.

“The integration with Solidworks is extremely valuable to the business. OpenBOM saves us time and ensures accuracy of our product BOMs.”

Engineers stay focused in their design environment. Product data syncs automatically. BOMs are created with a single click. That’s how you build a bridge between design and lifecycle—not with manual exports or disconnected PDM silos.

✅ 3. Connected Engineering + Operations = Real Collaboration

The real value happens when engineering and manufacturing share the same source of truth. A BOM isn’t just a design artifact—it’s a living piece of information that drives purchasing, inventory, and production planning.

That’s why NVTS uses OpenBOM not just to manage product data, but to streamline procurement and operations.

“OpenBOM is the single source for our material and production planning and purchasing. We consolidate material requirements into Purchase Orders by vendor, which reduces waste and cycle times.”

This isn’t hypothetical. It’s a measurable impact—reduced delays, clearer communication, faster vendor engagement. When the entire team shares one live, structured view of what’s being built, everyone moves faster.

✅ 4. From Data to Insight: Visibility That Drives Action

A modern PLM platform isn’t just about managing data—it’s about turning that data into insight. That’s where powerful visualizations, graph-based navigation, and full-lifecycle traceability come into play.

NVTS engineers fell in love with OpenBOM’s graph visualization tools.

“Everyone at NVTS loves the graph visualization. The new UI makes it so easy to open an item, click where used, and the world opens up right in front of you! It’s the Google map of our entire product structure. Start with one breadcrumb and find it all.”

This kind of visibility goes beyond BOM tables. It gives engineers and new hires alike the ability to understand relationships, spot dependencies, and reduce risk in product structures. It’s not just more data—it’s better decisions.

✅ 5. User Experience That Engineers Actually Enjoy

Let’s be real—engineers won’t use tools that feel clunky, slow, or archaic. The best software today feels intuitive, fast, and pleasant to use. That’s no accident—it’s intentional user experience design.

NVTS saw the impact of this immediately. From thumbnails to flattened BOMs, formulas, inventory links, vendor data, and purchase orders—everything in OpenBOM is designed to be usable and actionable.

“Full BOM from CAD, Thumbnail images, Flatten BOM, Formulas, Graph, Vendors, Purchase Orders, Inventory, and more. OpenBOM does it all for us.”

The result? Adoption happens naturally. Teams aren’t forced to use the system—they want to use it, because it helps them work smarter, not harder.

📉 The Bottom Line: 25% Less Error and Rework

Here’s the ultimate test: did the PLM platform help your business? For NVTS Global, the answer is a resounding yes.

“Simply put, OpenBOM reduced our errors and rework costs by 25%.”

That’s the metric that matters—not number of features or depth of documentation, but reduced mistakes, faster cycles, and lower costs.

Conclusion: 🔍 What to Look For When Selecting Your Next PLM/BOM Tool

To recap, here’s the modern stack that leading teams are looking for:

- Cloud-native and multi-tenant – No deployment delays or hidden infrastructure costs

- Web-based with native CAD integrations – Engineers stay productive in their preferred tools

- Collaboration across the full product lifecycle – From design to purchase order

- Data visibility and insight – Graph navigation, real-time updates, and clarity

- Delightful user experience – Built for engineers, adopted by teams

But more than any technical feature, make sure you’re asking this:

“How will this system help our team solve real-world problems?”

Because at the end of the day, that’s what you’re buying.

If Greg Klein’s story from NVTS Global resonated with you, you’re not alone. Thousands of companies are making the shift to modern, problem-solving PLM with OpenBOM.

💬 Want to See OpenBOM in Action? Let us show you how…

REGISTER FOR FREE or SCHEDULE A DEMO and start solving your product data chaos—today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.