What information should be included in a Bill of Materials? This is a question that is very often asked by engineers and everyone else. While a typical BOM is a list of components with their part numbers, balloons, and quantities, in real-life, you can find a lot of value in bringing additional information from CAD parts to a BOM.

CAD Information in BOM will make it more intelligent

Bringing some CAD information to a BOM can make it more intelligent and more valuable. Here are a few examples of information that our customers are looking at how to bring from CAD design to a BOM:

- Geometry (to perform calculations, make cultists and perform ordering)

- Mass (to perform analysis such as mass rollup and others)

- Material (to make manufacturing planners’ life easier).

When using OpenBOM, you can turn your BOM into a center of intelligence about your product and you don’t need to work hard to do so.

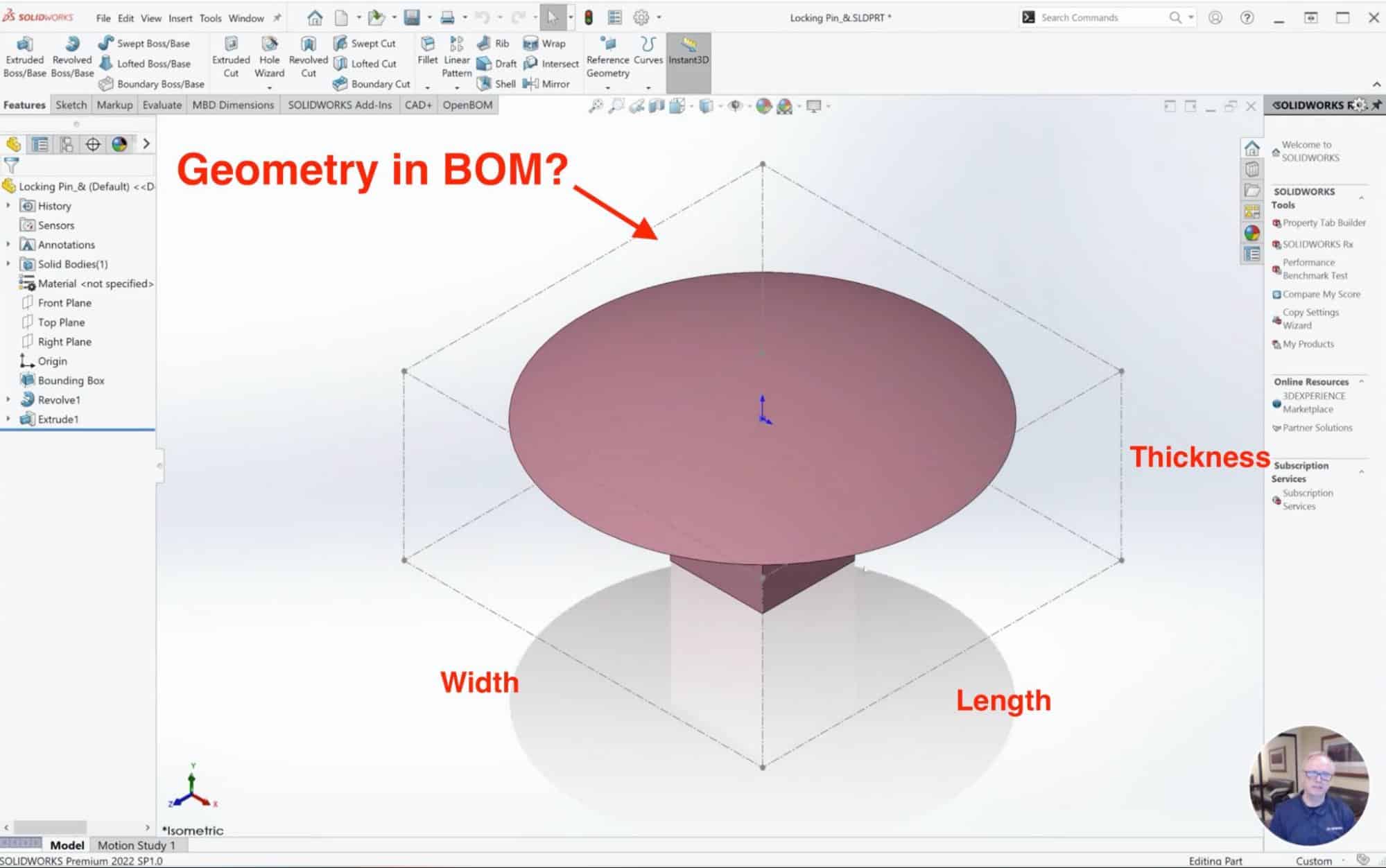

Among all these properties, geometry is my best example. In my blog today, I will show you a short video and give some tips on how to bring geometry information to a bill of materials created using OpenBOM automatically.

How to add geometry data from Solidworks

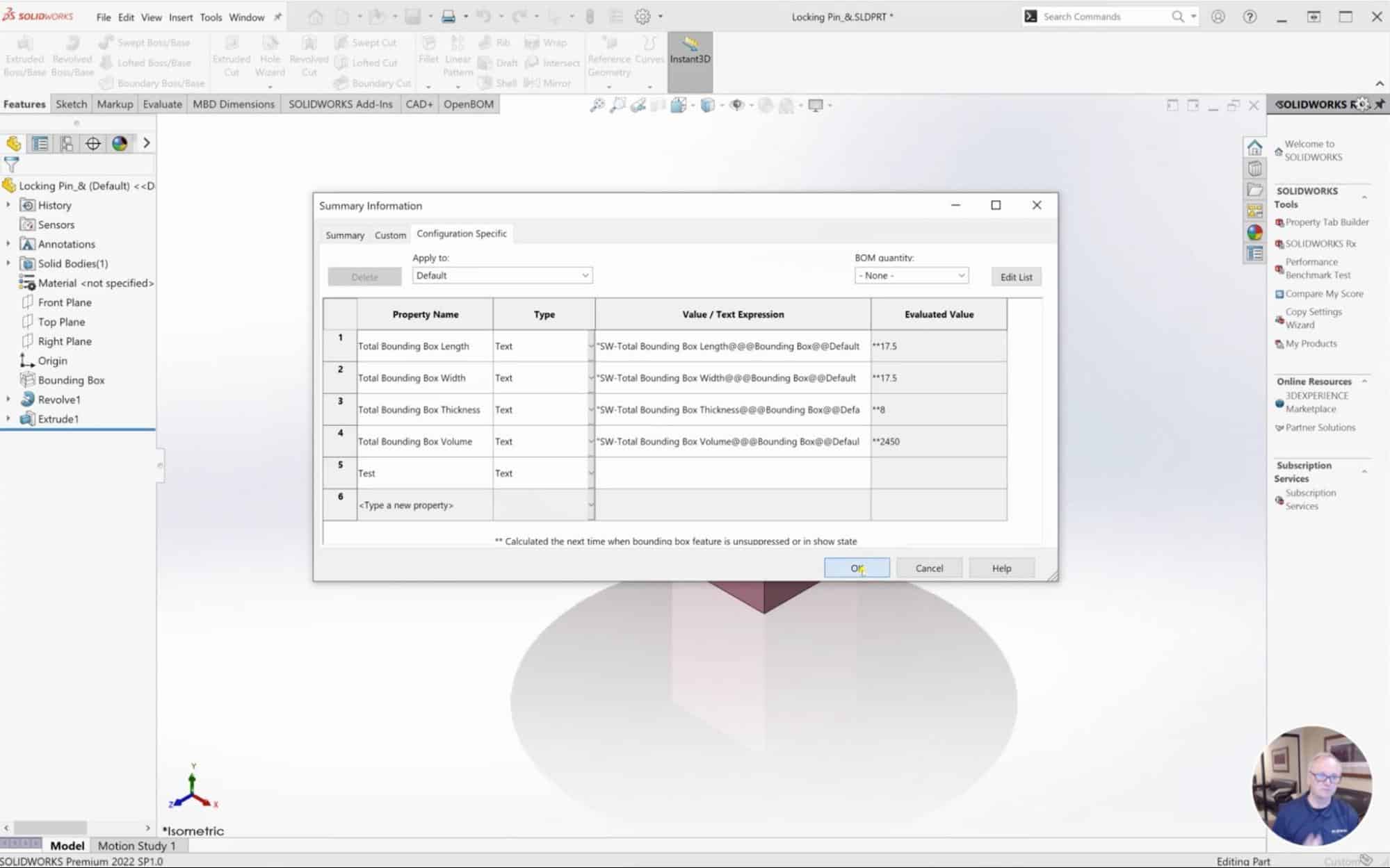

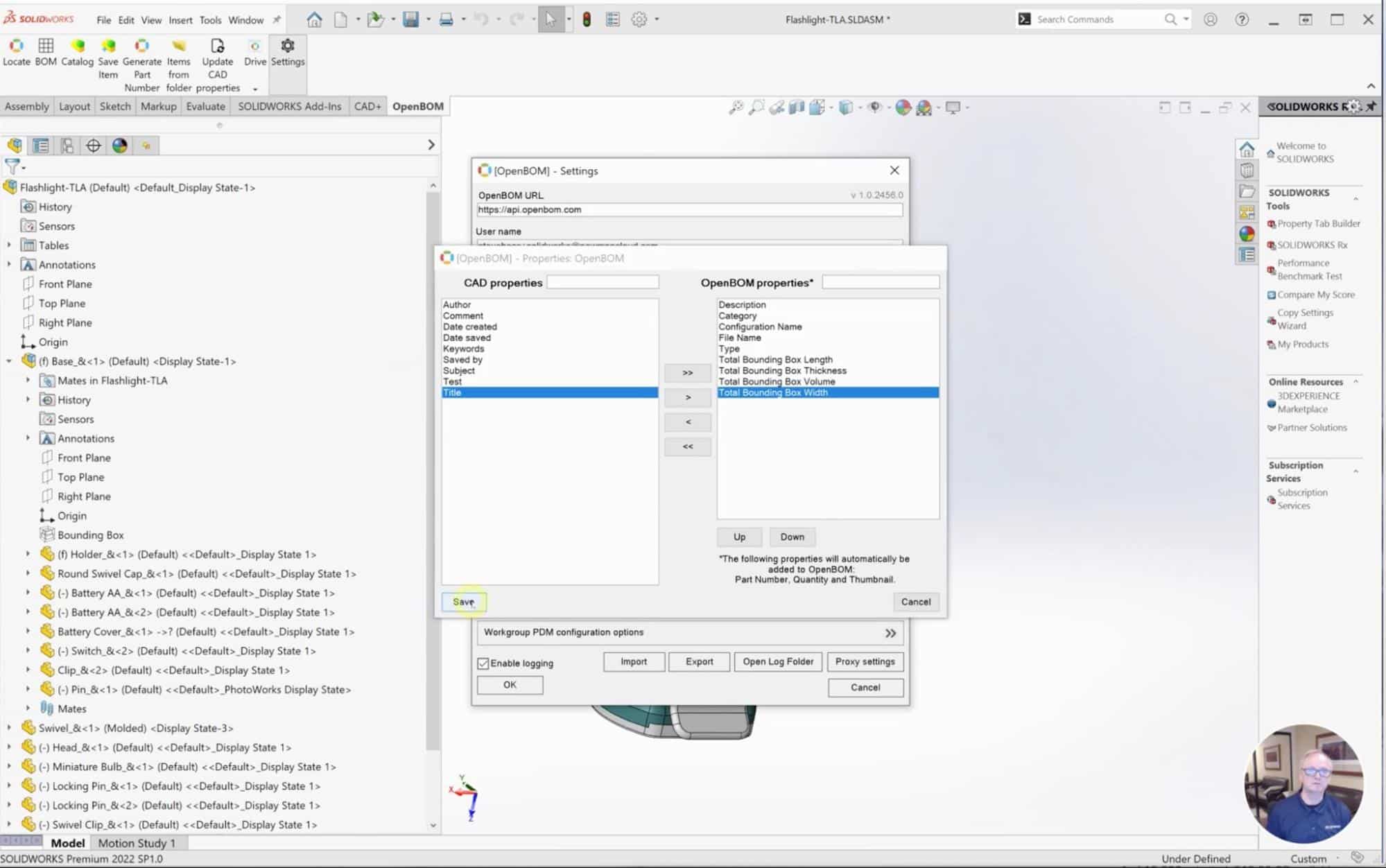

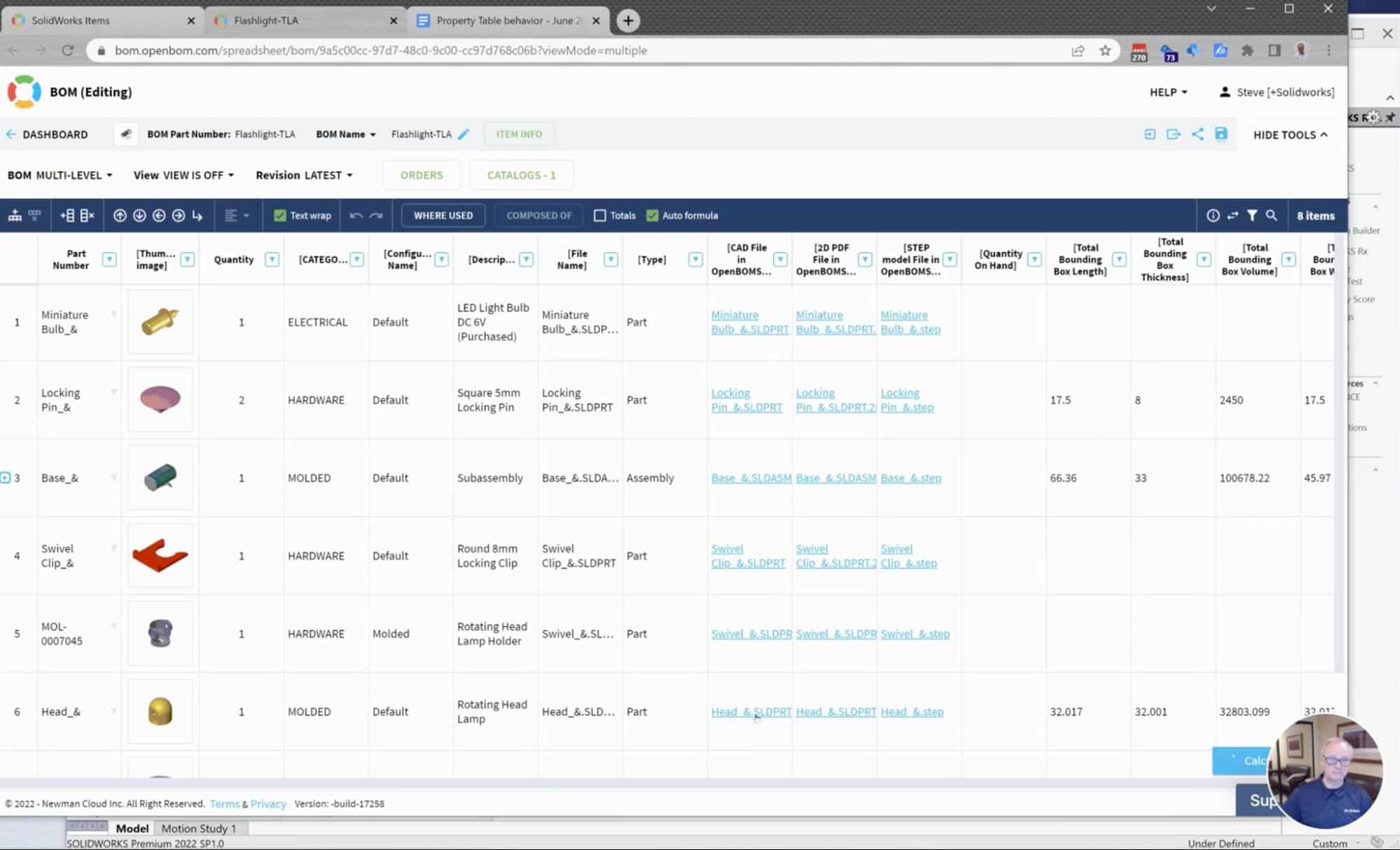

Here is a piece of quick information on how to add sizes (Length, Width, Thickness, etc.) to a BOM created using OpenBOM Add-in for SolidWorks. To do so, please follow these steps.

1) Create a bounding box

2) Map needed properties to config properties

3) Update OpenBOM property settings

4) Create / Update a BOM

You will get all needed information added to the BOM and it will be updated each time you create/update a BOM for Solidworks design.

Video Demonstration

Please watch a quick video demonstration about how to make it happen.

Conclusion

OpenBOM allows you to easily bring any information from CAD design to a BOM and make it available for a variety of useful tasks such as cost analysis, material planning, components ordering, cultist, and many others. Bringing such information to OpenBOM BOM, you will turn Bill of Materials into a center of intelligence about your product and make everyone’s life easier.

Are you still entering geometry parameters to your BOM manually? It can be a costly experience that should be stopped sooner than later.

REGISTER FOR FREE to OpenBOM and start a 14-day trial to check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.