Walk into any engineering office today, and you’ll see it immediately: Excel open on someone’s screen. Spreadsheets have been the backbone of BOM and engineering data management management for decades. They’re familiar, flexible, and always there when you need them.

But here’s the uncomfortable truth: Excel was never designed to manage the complexity of real products.

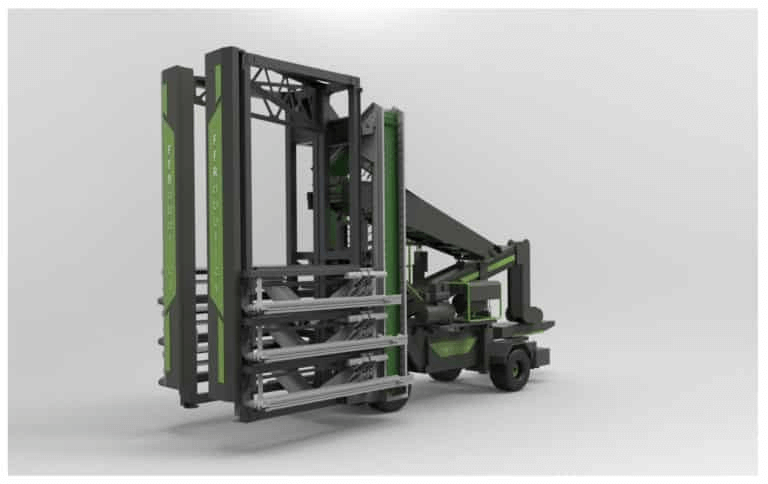

The Agricultural Equipment Story

Imagine you’re building a modern piece of agricultural equipment, like an automated harvester. But it can be any industrial equipment, robot, or complex product. To imagine what it looks like, check one of our customer stories.

At first glance, it’s just a list of parts – engines, wheels, hydraulics, electronics. But dig deeper, and you see a hierarchy of complex subsystems:

- The engine system with its diesel engine, cooling, and exhaust modules

- The hydraulic system powering the cutting head and conveyors

- The transmission system transferring power through gearboxes and shafts

- The robotic arm system with motors and joints for automated picking

- The computer vision system combining cameras, sensors, and AI processing

- The packaging system with conveyors and baggers to pack crops on the go

- The control system with embedded computers and operator displays

Each subsystem is effectively its own mini-product. Many of them share common parts like hydraulic fittings, electrical connectors, and fasteners, each with its own cost, supplier, and specifications.

Designs evolve daily. Components change, suppliers are replaced, and costs fluctuate. Managing these interconnected subsystems and shared parts demands more than a simple parts list – it requires a structured and flexible product data model.

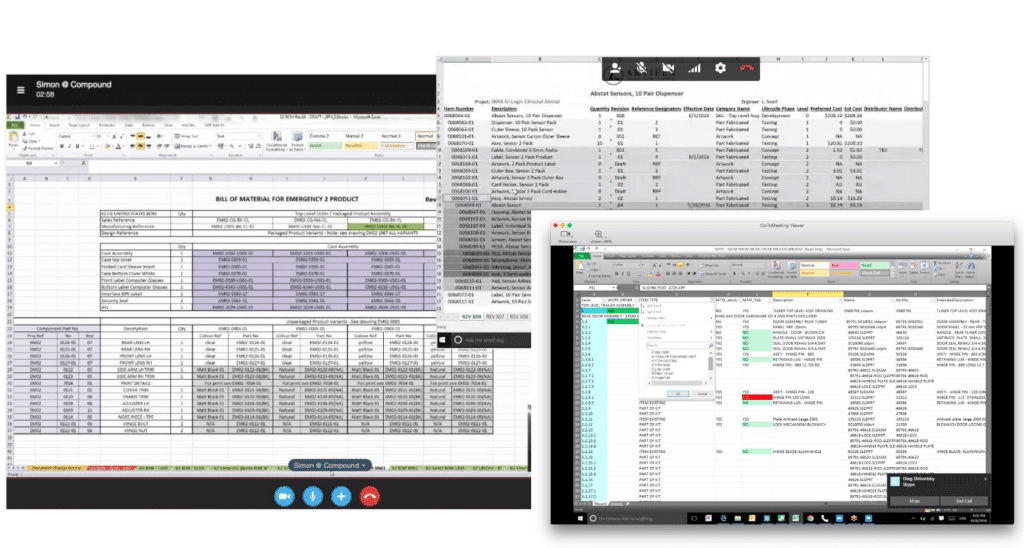

Where Excel Fails – A Reality Check

Excel might handle your first flat list. But the moment your BOM gains hierarchy, Excel starts to crack under the weight of reality. The moment you will try to manage changes in Excel, it will bring any sane person to a full stop.

Here are some real examples of Excel mess. We blurred some of the data, but they are real, and I’m sure you have some of these examples on your computers.

Excel Sees Only Rows and Columns:

Your beautiful 1.2.3 numbering? It’s just text to Excel. There’s no understanding of what’s a parent assembly, what’s a child part, or which subassembly is reused elsewhere.

Updates Become a Nightmare:

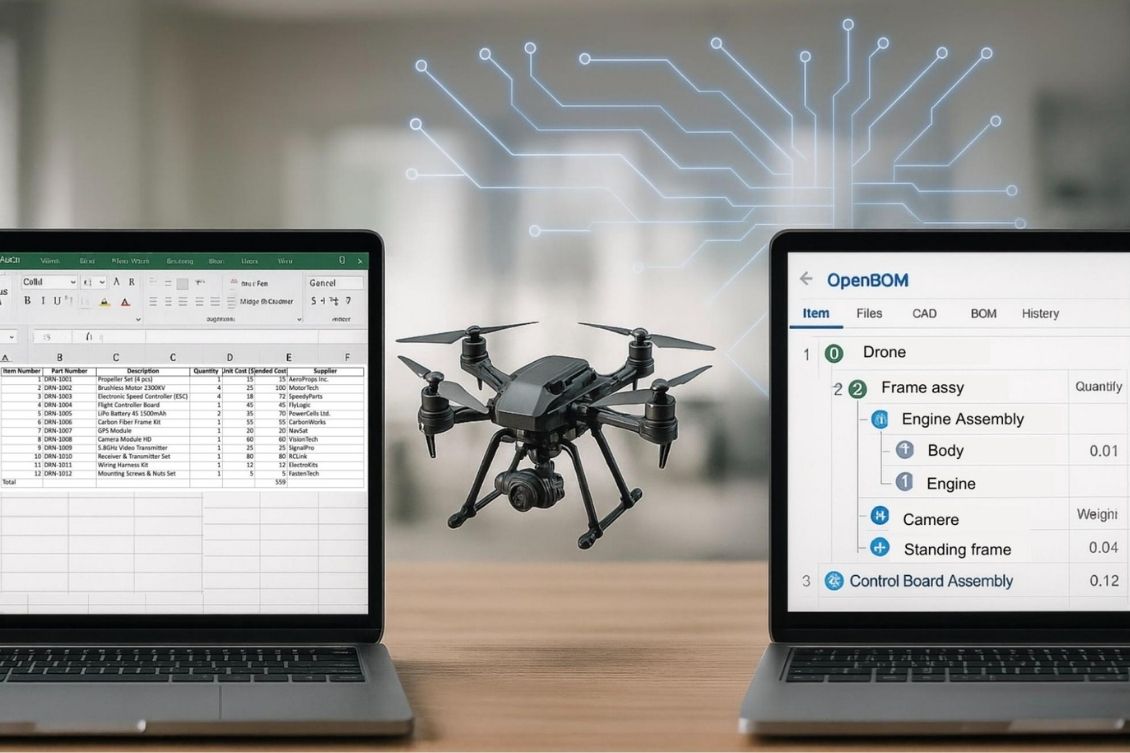

That battery module reused in two drone models? Excel treats each as a separate disconnected row. Update it in one BOM, and suddenly it’s out of sync in another. There is no single source of truth.

Rollup Calculations Turn Fragile:

Need to calculate the total weight or cost of motors across assemblies? Get ready to build complex formulas that break the moment your structure changes.

No Revision History or Traceability:

Who changed the connector spec last week? Did someone overwrite your update? Excel won’t tell you. Ordering off outdated BOMs becomes a ticking time bomb.

Collaboration Chaos:

Two engineers editing the same file can quickly overwrite each other’s changes, leading to lost data and hidden errors.

Disconnected Data:

CAD exports to Excel work – until you add supplier data, costs, or document links. The next CAD export overwrites your edits, leaving you reconciling two disconnected worlds.

Why Does Everyone Still Use Excel?

Because it’s comfortable. Because change feels risky. Because traditional PLM systems were expensive, rigid, and CAD-focused – leaving Excel as the fallback tool for BOM management.

But here’s the thing: comfort shouldn’t come at the cost of errors, delays, and missed parts.

How OpenBOM Helps You To Evolve

At OpenBOM, we asked: What if we kept what engineers love about Excel – the simplicity – but added what Excel will never have: true online data modeling for products?

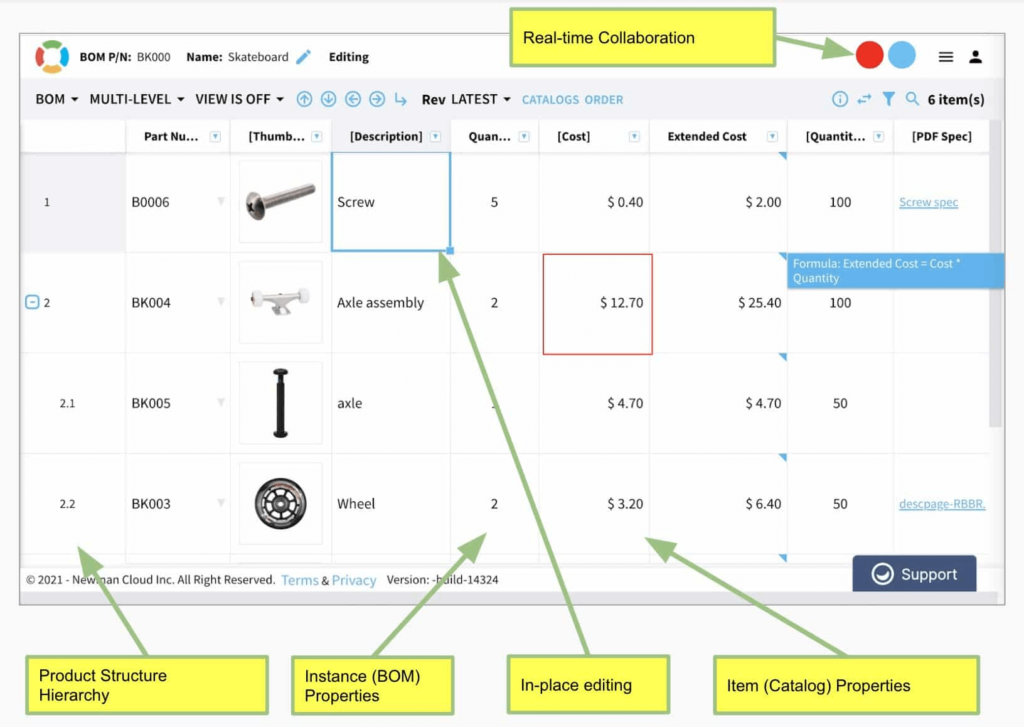

OpenBOM was built specifically to manage real product structures. Instead of rows and columns pretending to be hierarchies, you get:

- Multi-level assemblies with true parent-child relationships, so your structure is real data, not numbering tricks.

- Reusable subassemblies linked as single objects, ensuring updates are reflected everywhere automatically.

- Built-in calculations and rollups for quantities, costs, and weights that don’t break when your design changes.

- Version control and revision history for every item and BOM, so you always know who changed what and when.

- Integrated files and CAD data attached directly to your items, keeping everything in context.

Yet, despite this powerful data modeling backbone, OpenBOM feels like a spreadsheet. Its editing interface is familiar. You can drag-and-drop Excel files to import, analyze, and build your BOM structures automatically. And if you need to share with suppliers or customers, Excel exports are seamless.

But last, and very important is that OpenBOM helps you to get data in and export it out to Excel with the button click today and will be doing it even faster with a new import / export BOM AI Agent that is also a BOM agent that “speaks” files.

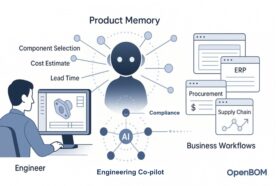

How Data Modeling is Connected to Coming BOM AI

Data is the foundation of AI. Without structured, contextual data, AI algorithms have nothing meaningful to analyze. OpenBOM’s data modeling isn’t just about making BOM management easier today – it’s about preparing for the future of BOM AI. By building accurate, structured BOMs with real parent-child relationships and connected information, OpenBOM creates a knowledge graph of your products. This structured context allows AI algorithms to perform advanced assessments, such as calculating total product cost rollups, predicting supply chain risks, or suggesting optimal substitutes in seconds. For example, BOM structured graph queries can return precise information about which components are reused across assemblies, or identify design dependencies that spreadsheets could never uncover. Without this data backbone, AI in BOM management is just wishful thinking.

Conclusion

Excel isn’t evil – it’s simply the wrong tool for today’s complex products and tomorrow’s AI-powered workflows. As your designs grow in complexity, with multi-level assemblies and reused components, spreadsheets fall short in delivering the accuracy, versioning, and structured data your team needs.

OpenBOM brings true online data modeling to your fingertips while keeping the spreadsheet simplicity that engineers trust. It doesn’t just organize your BOMs better today – it builds the structured data foundation required for the AI-driven insights and automation coming tomorrow.

Because building drones – or any complex product – deserves more than rows and columns. It deserves a system ready for what’s next.

REGISTER FOR FREE to explore what OpenBOM can do for you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.