How to stop using Excel to manage Bill of Materials (BOM) in a few days using OpenBOM?

This is a big question I’ve been asking myself for many years. My passion to replace Excel started with one of my first blog articles – Why do I like my PLM Excels? While it was clear to me why Excel is loved by so many people, I wanted to figure out why Excel is actually not a good thing – PLM Excel Spreadsheets: from Odes to Woes.

These articles were deep inside me when I decided to come with OpenBOM to develop the SaaS platform to replace PLM excels with something better that will be as good as Excel and at the same time, won’t have all problems Excel and other spreadsheets have.

You tried Excel or Google Spreadsheet and it didn’t work…

You’re an engineer in a manufacturing company that is working on design, engineering and production tasks individually or as part of the team. While you’re enjoying building innovative products and finding unique engineering solution, you’re struggling with the need to manage Excel files with a bill of materials, accounting for parts, quantities, rollup cost, mass, and many other management tasks, You continuously failing to communicate efficiently with other team members and the department responsible for production and purchasing. You’re stressed by the need to manually export data from CAD system counting parts, making updates.

You have tried different Excel and spreadsheet templates. You tried the Google spreadsheet. They are simple to start with, but they are getting complex within time. Also, spreadsheets are absolutely not fit if you need to manage nested structures, rollup quantities and having single data storage for parts – data is easy becoming redundant and everything is messed up. Also, sharing data with somebody else and updating it at the same time, is insanely complex. Data is often lost or not updated data is shared with the people that need to make purchases.

SaaS Applications Trends

SaaS is taking over the cloud computing market. Gartner predicts that the service-based cloud application industry will be worth $143.7 billion by 2022—a level of growth that will shape SaaS trends in 2020. As much as 80% of organizations are predicted to migrate toward the cloud by 2025. In 2018, public cloud adoption grew to 92%. According to Tech-Clarity research, cloud /SaaS software helps companies to achieve a greater value on their path to improving innovation and engineering performance. Implementing engineering and manufacturing software in the cloud (SaaS) offers value across multiple dimensions – operation, business, engineering advantage, strategic.

Staying with old fashion Excel spreadsheet, you can expose yourself to potential mistakes, production delays, excessive cost, and missing production targets. Somebody else will come to your place and will eat your lunch by developing products faster and at a lower cost.

By deferring to existing non- SaaS PDM and database solutions, you put your manufacturing and business goals at risk, exposing to significant IT and operational costs. By continuing to manage data using Excel and the variation of spreadsheets, you’re exposed to painful mistakes such as wrong orders and delays.

Here are several examples of companies who did it using OpenBOM.

Meantime, let me share a few examples of companies that escaped Excels and spreadsheets and can manage product data and the Bill of Materials using OpenBOM.

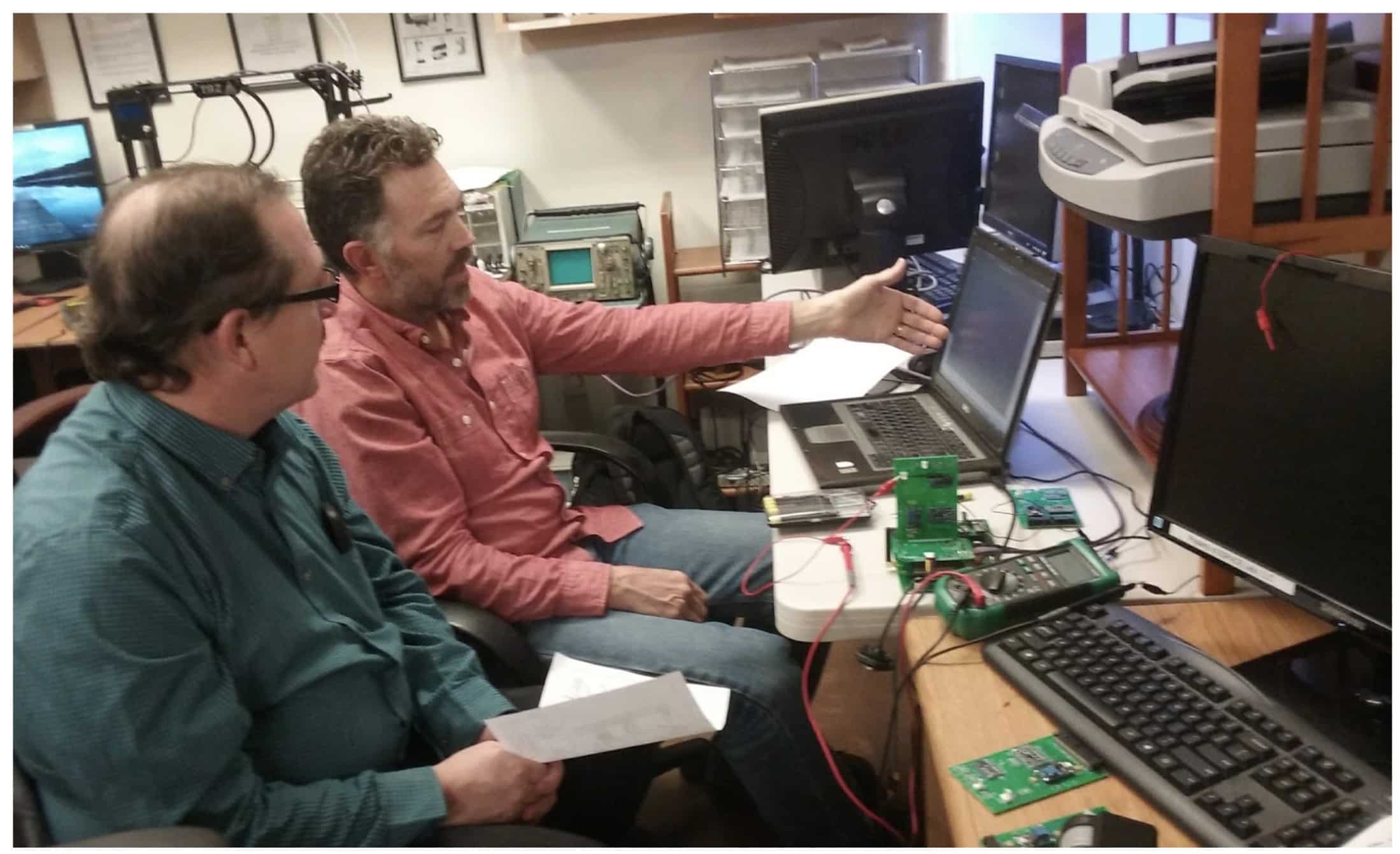

E::SPACE Labs

The company moved from messy data organization and data spread over multiple places coming from Autodesk Fusion 360 and Autodesk Eagle to structured information using OpenBOM. E::SPACE: OpenBOM gives us structure and discipline to keep track of our important designs.

David Robson one of the founders of E::SPACE Labs says:

“The multi-disciplinary aspect of OpenBOM and the only one of it’s kind integrations to Autodesk Eagle and Autodesk Fusion 360 save us valuable time and greatly improve accuracy and reliability”

In another example, IMBU moved from a complex and not automated environment to a simple way to organize data using OpeBOM. IMBU is using Onshape and OpenBOM integrates well into the Onshape environment.

“The OpenBOM / Onshape suite of tools works extremely well for us. OpenBOM creates both Catalog inventories and Multi-Level BOMs directly from our Onshape models”. Says Byron van Gool IMBU Mechanical Engineering Manager. “We rely on the ability of OpenBOM to integrate tightly with our Onshape design structure and create a Multi-Level BOM. We then connect our OpenBOM item master catalog to that BOM to enable reuse of our extensive items catalog”

IMBU

IMBU also uses OpenBOMs unique formula feature to perform multi-level calculations for pricing. “The ability to rollup the cost of sub-assemblies and items in a BOM to the top-level saves us hours and hours of manual calculations”, says Gert.

Similar to our own IMBU Web Suite of monitoring tools, OpenBOM runs entirely with a web browser. “We like the simplicity and portability of that,” says Gert. “It just works!”

In another example, CATIM, an electric equipment manufacturer from Australia using OpenBOM to move from manual process to automated environment managing BOMs and related information literally saving hundreds of hours a year using OpenBOM.

Here is what CATIM Design Manager says about OpenBOM usage:

CATIM discovered OpenBOM out of simple necessity. “We needed some way to make a BOM from Autodesk’s Fusion 360,” says their Design Manager. “I went to my keyboard and quickly discovered OpenBOM. We gave it a try and are now saving literally hundreds of hours a year with OpenBOM”

X-Naut

Long Beach, California based X-Naut making the entire X-naut team from design to supply line to manufacturing rely on OpenBOM and moving away from not organized data in Excels.

X-Naut is using Solidworks and creates Catalogs, BOMs necessarily to make their products directly from Solidworks using OpenBOM add-in.

As demand for the unique products quickly grew X-naut found themselves hustling to managing the components and supply lines necessary to meet the expanding demand. X-naut relies on OpenBOM to quickly capture the product structure form the 3D CAD designs and create the Items, Catalogs and Bills of materials necessary to produce their products.

“The ease of use coupled with the production planning features of OpenBOM give us the ERP features we need without all the ramp time, cost and maintenance of an on premise system,” says X-naut CEO Darren Saravis. “OpenBOM’s ability to quickly bring together design and vendor information into a purchase order and manage quantity on hand helps us manage demand and inventory at our off-shore facilities”.

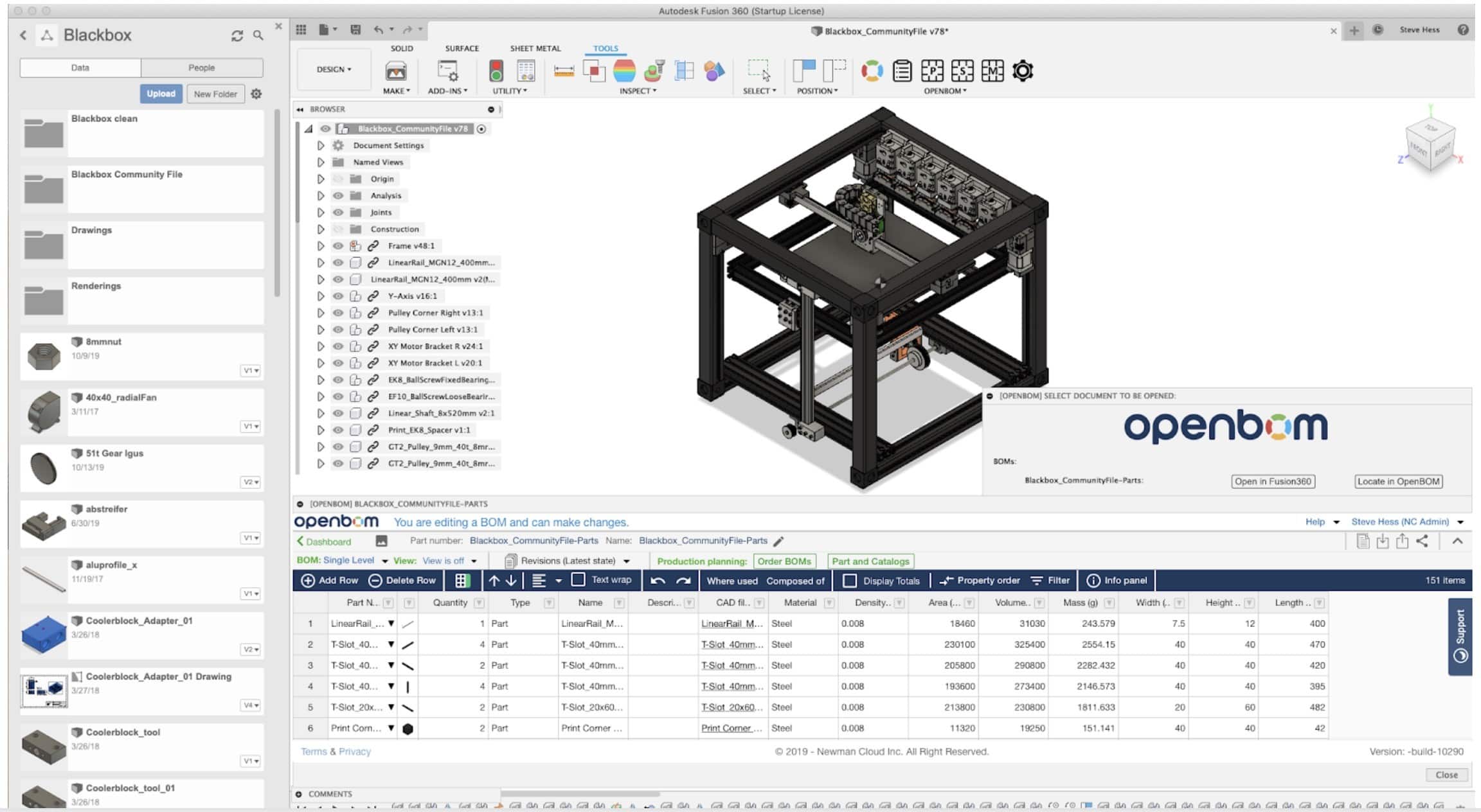

LayerShift project

Marc Schömann and the LayerShift project was manually capturing BOM and related information for his 3D printer design using Autodesk Fusion 360. He was struggling with non-organized data and was looking to clean the messy information into a manageable environment.

OpenBOM gives him this opportunity and data now is completely under control allowing him to manage BOMs and coordinate purchases. .

“Our distributed team used OpenBOM to capture product structure and assembly and part data from Autodesk Fusion 360 then create bills of material for purchasing the components we needed to build the printer,” Marc said. “The OpenBOM Fusion 360 integration made it easy to create and update BOMs and Part Catalogs and to identify and specify vendors as the design moved forward.”

Conclusion

Here is the truth: You can easily escape messy Excels and stop doing manual Bill of Materials calculations. However, here is the thing – most software products out there are not equipped with a unique set of functions and capabilities as OpenBOM.

OpenBOM gives you a unique way to change what you do with the Bill of Materials and other related tasks in less than fifteen minutes. It is because of unique technologies and CAD integrations we developed at OpenBOM.

Wait for my next article where I will bring you a recipe on how to do so,

Check what OpenBOM can do today subscribing to OpenBOM here or request a trial version.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.