How product memory transforms engineering workflows to introduce AI agents

When I talk to engineering and manufacturing teams, the conversation almost never starts with technology. It starts with a pause and then with problems the engineering team wants to solve.

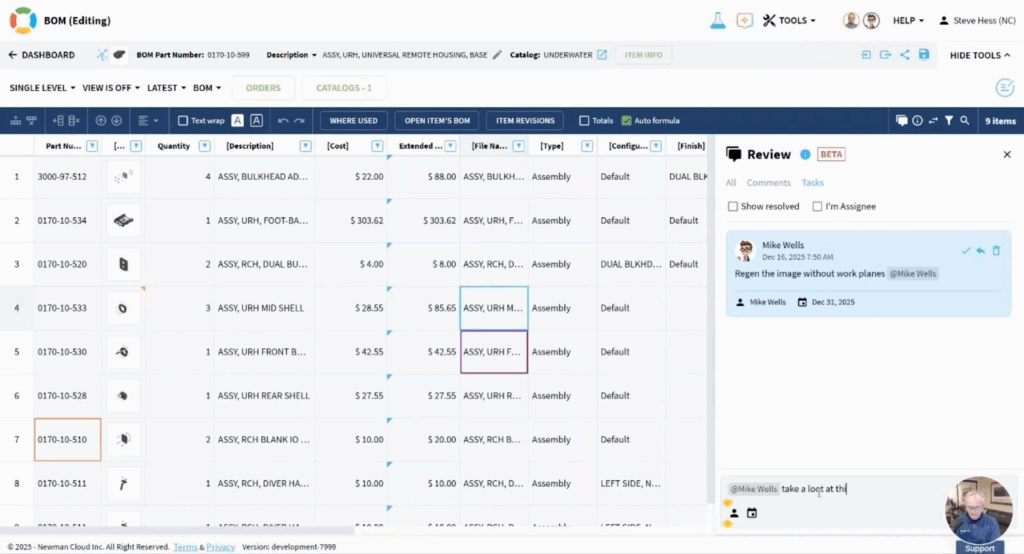

Someone has a bill of materials open on their screen, or a product structure that is close to being ready, but not quite. A few people still need to look at it. Some questions are open. There are a couple of alternatives on the table. And before anyone pushes this work forward, the team wants to be confident that nothing important is missing.

This moment is familiar, and it’s not a sign of dysfunction. It’s a sign that the work matters.

That everyday tension of needing to move forward while information is still incomplete has been driving much of my recent thinking and writing.

In one article, I reflected on where OpenBOM is heading in 2026, and why a new concept “product memory” is becoming foundational for engineering and manufacturing work. It is not a feature, but a response to how decisions actually happen across teams.

In another article, I stepped back from the “AI-native” noise and focused on what really needs to change next, especially the intention to enable collaborative work for humans and AI, rather than adding intelligence on top of fragmented workflows.

Those articles talk about direction and intent.

Today, I want to talk about what that direction looks like in the middle of real work — when a team is reviewing, questioning, and deciding, and when clarity matters more than speed.

The Review Moment

Most multi-person reviews start with the right mindset. Someone asks for input. Others want to contribute their perspective. Engineering is thinking about design intent, manufacturing is thinking about feasibility, procurement is thinking about availability and cost, and sometimes compliance or service has questions of their own. Mechanical engineers, electronic engineers, production and supply chain managers – all need to work together.

The problem is not the diversity of perspectives. The problem is that the review itself often has no single place to live.

So the work gets exported. A spreadsheet appears to capture comments. Screenshots are shared to explain context that didn’t survive the export. Conversations move to chat and email. Meetings get scheduled to reconcile different interpretations of the same data.

None of this is irrational. These are coping mechanisms teams use to get through uncertainty. But every step away from the product structure weakens the connection between decisions and the work they affect. By the time a decision is made, part of the reasoning already lives somewhere else.

The product keeps moving forward, but shared understanding struggles to keep up.

Unclear Change

When people say that change feels risky or unclear, they are often describing something very specific. They are not afraid of making a decision. They are trying to evaluate multiple possible futures at the same time.

What happens if we choose this component instead of that one? What does it do to cost, lead time, manufacturability, or supply risk? What assumptions are we making, and which of those assumptions might break?

These questions don’t fit neatly into an approval checkbox. They require comparison, explanation, and context. When there is no shared place to evaluate these “what if” scenarios together, teams either delay decisions longer than they want to, or they move forward with unresolved uncertainty that resurfaces later in much more expensive ways.

The issue is not speed. It’s a clarity.

“Product Memory” in Practice

A product memory-enabled workflow does not eliminate uncertainty. It gives uncertainty a place to exist while work continues.

Instead of treating questions, assumptions, and alternatives as side conversations, they become part of the work itself. When someone asks why a certain option was chosen, the answer doesn’t require reconstructing a meeting from memory or searching through email threads. The reasoning is already there, connected to the product structure that decision shaped.

This is not documentation created after the fact. It is thinking captured as it happens, while it is still relevant and before it fades.

In this kind of workflow, review stops being a gate you pass through and becomes a shared thinking process that moves the work forward.

A Shared Decision Flow

Imagine a product structure that is evolving toward release. It is not final yet, but it is visible to everyone who needs to contribute. Early visibility doesn’t mean chaos; it means that questions surface sooner, when they are easier to address.

At some point, a concern appears. A part may become unavailable. A cost target may be at risk. A manufacturing constraint raises a red flag. Instead of disappearing into a private spreadsheet or a side conversation, that concern becomes explicit, attached to the part of the structure it affects.

Alternatives are discussed in context. One option might be cheaper but harder to source. Another might be more available but require a design adjustment. These tradeoffs are not abstract. They are tied to real data and real consequences, and they are visible to everyone involved.

Before anything is finalized, the team reviews the situation together. Not to check boxes, but to make sure the implications are understood and that no critical perspective is missing. When a decision is finally made, it is not just a choice. It is a conclusion reached with shared understanding.

That decision is remembered. Not as folklore, but as context that stays connected to the product.

Revision with Context

Revisions are often treated as snapshots, a way to say “this is the new version.” But without context, a revision only tells you that something changed, not why it changed.

In a product memory-enabled workflow, revisions carry more than structure. They carry intent. They reflect which alternatives were considered, which assumptions were accepted, and why this version exists in the first place.

This doesn’t slow work down. It makes future work calmer. When change is needed again, the team starts from understanding instead of from scratch.

Downstream Confidence

The impact of this kind of workflow becomes most visible downstream. Manufacturing no longer has to interpret intent from static data. Procurement doesn’t need to guess which alternatives are acceptable and which were already rejected for good reasons.

When questions arise, they don’t trigger panic or rework. They trigger understanding. The team can see not only what the current structure is, but how it came to be.

Progress becomes smoother, not because mistakes disappear, but because decisions are no longer disconnected from their reasoning.

AI as a Participant

Once product memory exists, something else becomes possible. AI agents can participate in the workflow without inventing context.

They can analyze structures to surface inconsistencies or unresolved questions. They can validate whether a product is actually ready to move forward based on what has been reviewed and decided. They can recommend options by looking at past decisions and similar situations, not just at raw data.

This does not replace human judgment. It reduces the manual checking and mental load that teams carry today, because the system finally understands the work in the same way people do.

AI becomes useful not because it is smart, but because the workflow has memory.

Conclusion: From Documents to AI-enabled Collaborative Workflows

The question of how to organize engineering workflows for faster AI adoption is on the top of our minds. AI does not struggle in engineering and manufacturing because the algorithms are weak. It struggles because the workflows it is asked to assist are fragmented, incomplete, and disconnected from the reasoning that produced the data.

When decisions live in meetings, emails, and side spreadsheets, AI has nothing solid to reason on. At best, it can analyze static artifacts. At worst, it guesses intent that was never captured in the first place.

This is why transforming the workflow matters more than adding intelligence.

An AI-enabled collaborative workflow starts by changing how teams work together before any AI is introduced. It creates a shared space where uncertainty is visible, alternatives are discussed in context, and decisions carry their reasoning forward. Product structures are no longer just outputs of work; they become living records of how decisions were made.

Once that foundation exists, AI adoption becomes much faster and much more practical.

AI can analyze work because the assumptions are visible.

It can validate readiness because reviews and decisions are explicit.

It can recommend next actions because past choices and tradeoffs are preserved.

Most importantly, AI no longer needs to replace judgment or shortcut thinking. It supports the workflow by reducing manual checking, surfacing gaps early, and helping teams move forward with confidence.

In that sense, AI is not the starting point. It is the outcome.

Teams that want to adopt AI faster don’t need smarter tools first. They need workflows that remember what happened, why decisions were made, and how uncertainty was resolved.

When engineering workflows are transformed this way, AI stops being an experiment and starts becoming a natural participant in everyday work.

That is what an AI-enabled collaborative workflow really looks like.

Want to discuss the new OpenBOM Collaborative Workflows and how they can help your organization? Contact us by email—we’d be happy to talk.

In the meantime, REGISTER FOR FREE to see how OpenBOM can help you.

Best,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.