Manufacturing is transforming. It is not a single company that builds everything in one place. It is more reminding a network of entities working together. A network of suppliers, contractors, off-the-shelf parts manufacturers, and OEMs are building products these days. As much as manufacturing advanced, data management and product lifecycle management systems are still lagging behind. Legacy PLM systems are built for a single company rather than for a network. At OpenBOM we’re developing a digital thread platform that solves the problem of manufacturing data management silos.

The digital thread is a concept in manufacturing and engineering that refers to the seamless integration of data and information throughout the entire product development and manufacturing process. It involves connecting all data and information related to a product, from design and engineering to manufacturing and maintenance, into a single, cohesive system. Check my earlier articles about the digital thread.

The digital thread is important because it allows for improved efficiency, collaboration, and decision-making throughout the product development and manufacturing process. By having all relevant data and information connected, it becomes easier for different teams and departments to access and use the information they need, leading to more streamlined processes and faster time-to-market. Additionally, the digital thread enables the use of advanced analytics and digital twin technology, which can be used to optimize product performance, predict and prevent failures, and improve overall product quality. Read more about digital thread in manufacturing and OpenBOM featured on Media Coverage.

Manufacturing Networks Modern Data Management

Manufacturing networks require scalable data management because they generate and collect large amounts of data at various stages of the product development and manufacturing process. This data includes information on product design, engineering, materials, manufacturing processes, and performance. This data must be stored, managed, and analyzed in a way that is efficient and effective and can be accessed by the different teams and departments that need it.

Scalable data management systems allow for the storage, management, and analysis of large amounts of data, and can adapt to the changing needs of a manufacturing network. These systems can handle the data generated by multiple sources, such as sensors and machines, and can store and organize it in a way that is easy to access and understand. Additionally, they can be integrated with other systems, such as simulation and modeling tools, to enable advanced analytics and decision-making.

In short, scalable data management is essential for a manufacturing network as it allows for efficient collection, management, analysis, and sharing of the large amounts of data generated across the product development and manufacturing process, which enables better decision-making, optimization of the manufacturing process and the ability to predict and prevent failures.

Digital Thread and Connected Lifecycle

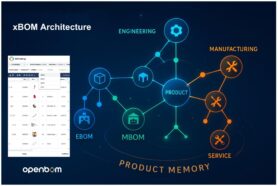

The digital thread represents and connects product information and allows companies to manage processes across multiple lifecycle stages and domains. The data can be managed in many places, but it is important to make it connected semantically and map/link with the right data sources. Such a model allows companies to build a set of connections between a variety of lifecycles regardless of where these processes go.

Multi-tenant data model

Legacy data management solutions, including PLM systems, have never been built to manage information that belongs to a specific company. It was always a “database” that contain information about a specific company. Connecting the data coming from the different lifecycle stages will turn it into a digital continuum that will replace monolithic PLM platforms.

Objects and Graphs

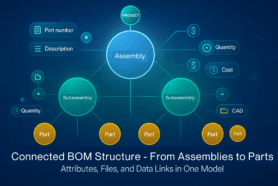

The foundation of the OpenBOM data model is a system of flexible objects. These objects represent the data (eg BOM, catalog, item, order), but in the near future, OpenBOM will expand the data model and will allow customers to create their own object types. Check for more here. I’ll be coming with more information and examples soon.

Conclusion:

OpenBOM data management foundation allows you to build a scalable information space to support product lifecycle and create semantic relationships between pieces of data belonging to different products, disciplines, companies, and processes. The flexibility of the OpenBOM data model allows you to map and connect information from multiple data sources. Multi-tenant architecture of OpenBOM allows the connection of information from multiple business entities. Such a foundation quickly became a scalable data management platform for a distributed network supporting the operation of multiple business entities connected together. This is a holistic model of the digital thread supporting manufacturing transformation and the building of intelligent web services.

REGISTER FOR FREE to OpenBOM, start your 14-day trial, and see how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.