Collaboration is the focus of many people in engineering and manufacturing companies these days. Even before COVID started, companies started to look at how to make collaboration and communication more efficient. These days collaboration is imperative for many companies that switched to completely remote work. In this remote working environment, CAD files can literally slow you down.

CAD Files

CAD files are historically the main media to store design information. At the same time, CAD files are one of the major factors making collaboration hard. Check my recent article about – Who wants to kill the CAD file? to learn about trajectories of CAD companies working how to remove CAD files blocking inefficient data management.

The files are here, but I can see some cracks in the way files are used, which can indicate changes that are coming. Although they know about files, the whole idea of using a file as a piece of information is becoming foreign to many kids (I’m not speaking about computer geeks). Instead, they use website paradigms and online documents (a-la Google docs) to refer to the information. The same about the applications. The idea of running an app as a “.exe” file is something that seems to them as strange and, instead, the app is something that either available on the mobile device or goes via the browser.

Going back to engineering and manufacturing software, things are divided into two major groups – (1) Files; (2) Databases. For a very long time, the first group was a clear winner. All CAD systems were storing data in CAD files. The same CAD files used to transfer information, data sharing between people, and different applications using the data. It is still the case and I believe a majority of product design data is managed in CAD files today. But, the changes are on the horizon. Because I can see CAD companies that are strategically focused on how to kill CAD files.

Downstream Collaboration

While CAD files are still representing the majority of design information today in production, we’ve been thinking about how to simplify the collaboration and improve data transparency in downstream processes. Think about costing, production planning, procurement, work with contractors and suppliers.

At OpenBOM, we’ve been thinking about how to help companies to collaborate, but at the same time not to demand a complete switch from CAD files.

OpenBOM CAD Add-ins and Collaboration

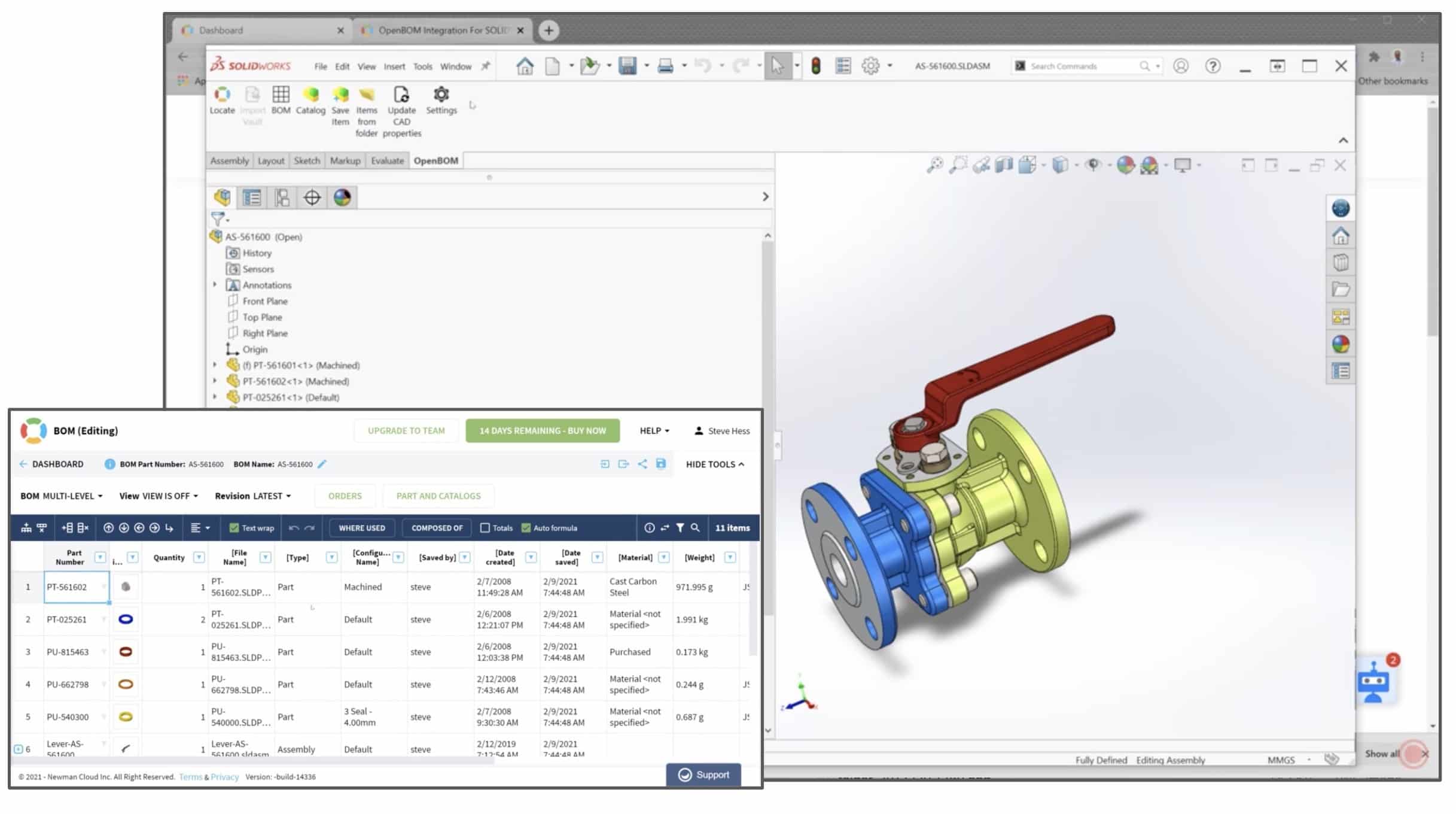

OpenBOM is a platform that captures the data and helps you to collaborate in a most seamless and easy way. OpenBOM captures data from CAD using our integrations and uploads all information on the cloud. OpenBOM share functions allow multiple people to be on the BOM and make communicate efficiently.

Here is one example that demonstrates how you can get started with OpenBOM and Solidworks under 5 min including OpenBOM registration and starting the trial. Watch the video and tell me what do you think.

Conclusion

Modern cloud services are capable to capture information and make it instantly available for collaboration between teams and companies. OpenBOM developed unique collaboration technologies and CAD integrations. It captures engineering data and provides you instant access to a very flexible and intuitive spreadsheet-like collaboration environment for seamless engineering collaboration.

Register today for free and start a 14-day trial to experience OpenBOM.

Best, Oleg

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.