How often you use Solidworks and have a situation where you model assemblies but later buy them as “purchased assembled” (bearings, pumps, etc). On average 70% of parts and assemblies in the product you manufacturing are either outsourced or purchased. Purchased and outsourced assemblies can be great to optimize cost and work optimization, but it can be a royal pain to manage.

The reason for the complexity is that in most of the cases, you would prefer to keep the assembly with all parts in your CAD design, but you need to exclude it from your BOM. Obviously, you don’t want all screws and other parts of the purchased assembly to mess up together with all other parts you actually need to buy and to bring to the shop floor.

Today, I want to show you an improvement in OpenBOM add-in for Solidworks that will help you to manage Purchased assemblies in Solidworks. It will allow you to keep them in Solidworks design, but exclude it from the BOM. It is useful when you use Solidworks and have a situation where you model assemblies but later buy them as “purchased assembled” (bearings, pumps, etc)

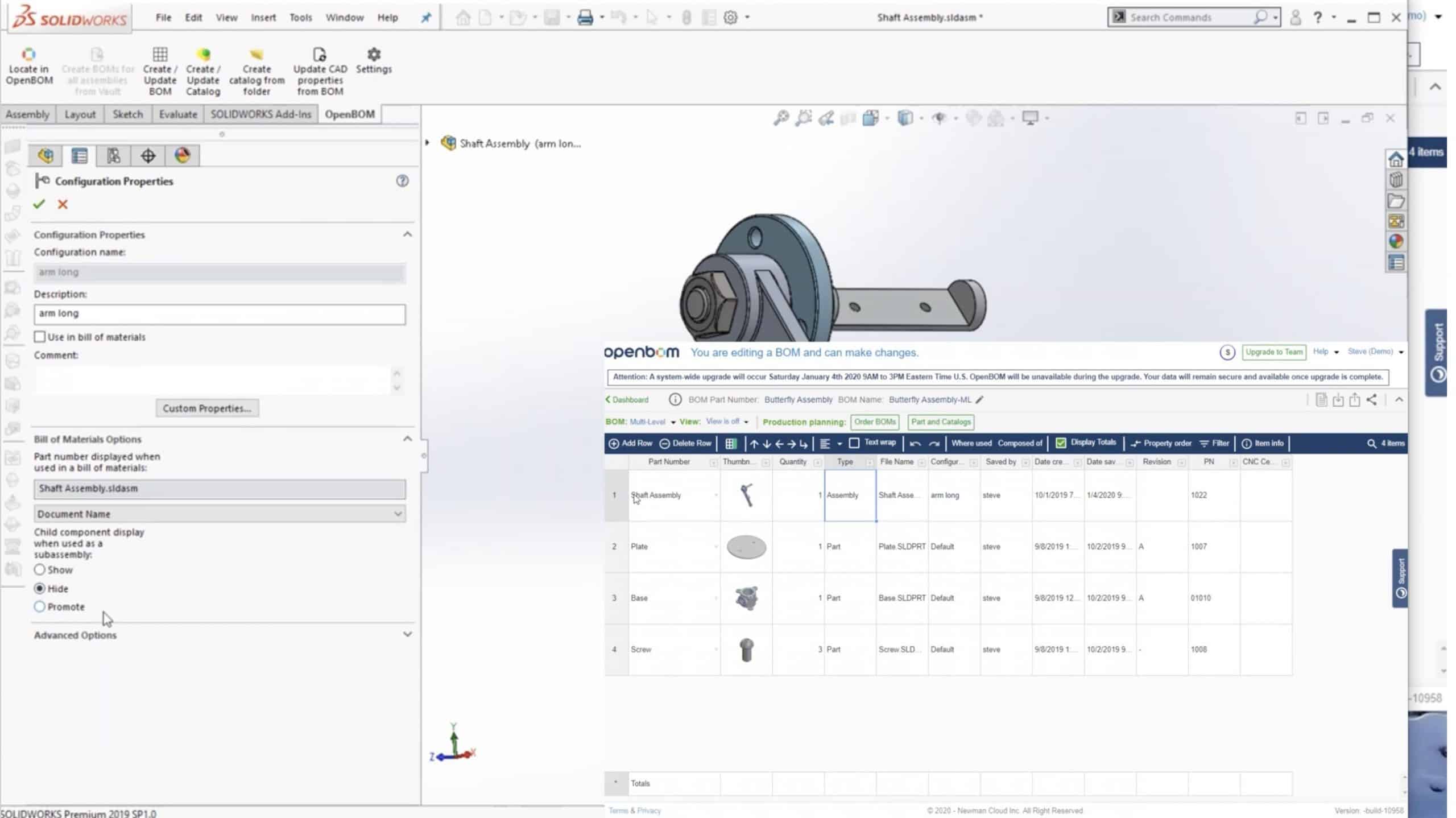

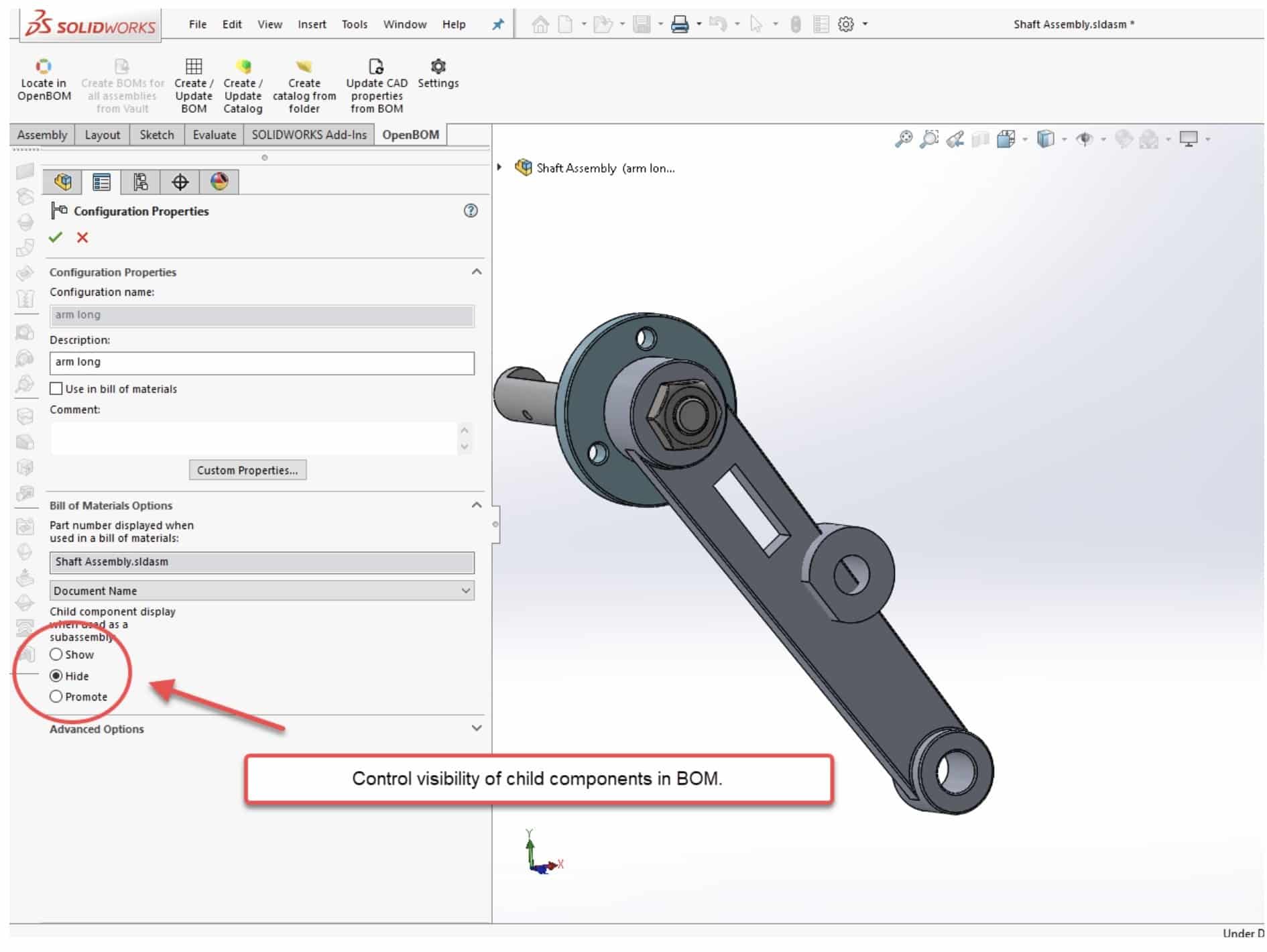

To do so, you can use Hide or Show configuration parameters in Solidworks. Check this out.

This parameter controls the visibility of child components in BOM. By setting it to “Show”, you will bring all sub-levels of the assembly to the BOM. By setting them to hide, you will bring an assembly, but all sub-levels will be gone.

This parameter controls the visibility of child components in BOM. By setting it to “Show”, you will bring all sub-levels of the assembly to the BOM. By setting them to hide, you will bring an assembly, but all sub-levels will be gone.

Check this video that demonstrates how it works.

Conclusion.

At OpenBOM we are trying to deliver the most intelligent set of options to extract data from your CAD assembly and convert it into the most useful Bill of Materials. All operations and synchronizations between the CAD system and BOM data are painful and can lead to many additional manual adjustments. OpenBOM eliminates this extra work and delivers the best results when you need to create a BOM for Solidworks assembly.

Check OpenBOM today – register to OpenBOM (Free) User Subscription.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.