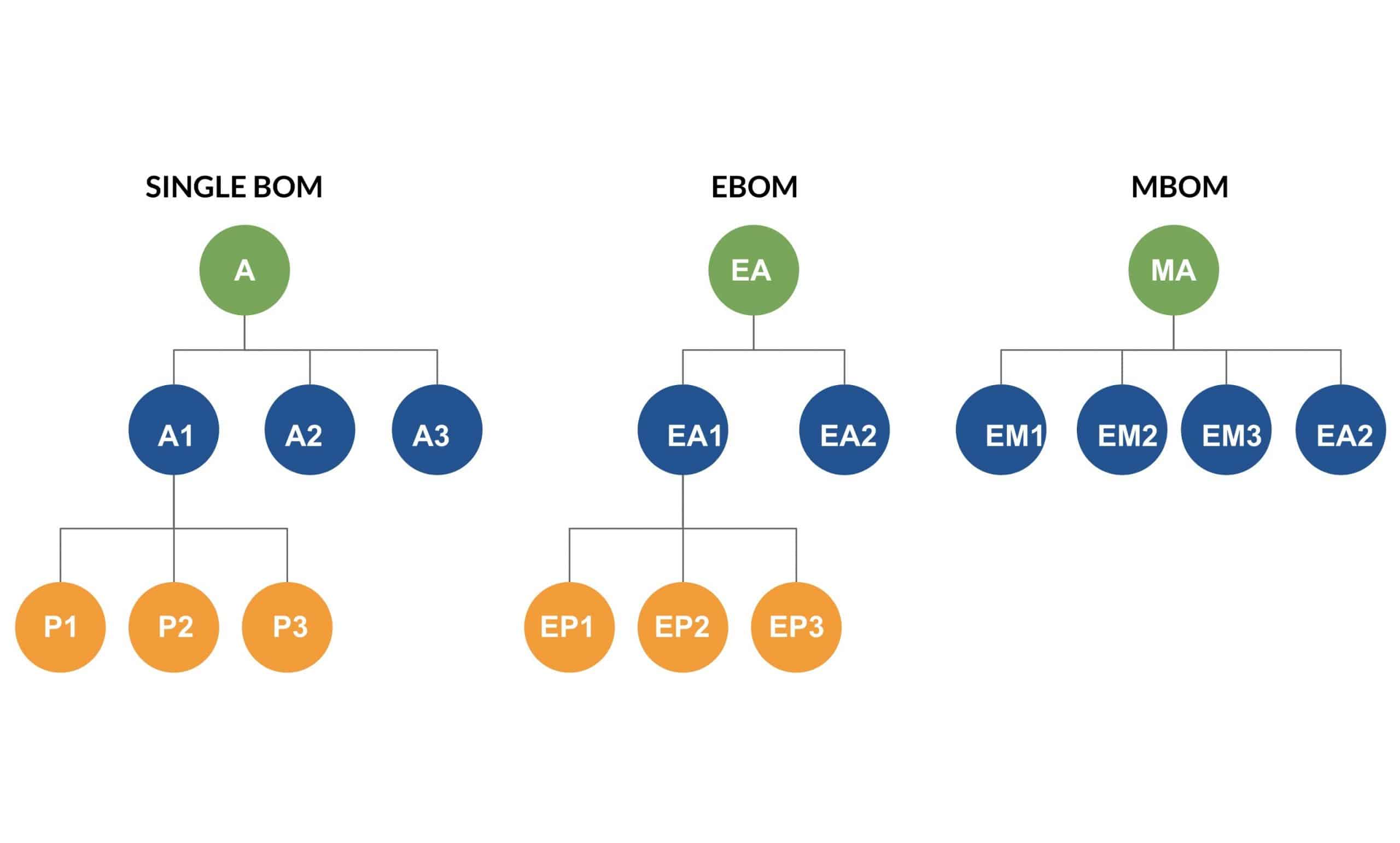

One of the most complex things in engineering data management is to coordinate two BOMs – engineering BOM (EBOM) and manufacturing BOM (MBOM)… Oops. Did I just say we need to coordinate two BOMs? Does it mean we must have two BOMs? Or maybe we can have a single BOM? These few sentences above can lead to tons of endless debates in manufacturing companies. Today, I want to discuss both and also give you some ideas on how OpenBOM can help you to deal with EBOM and MBOM regardless of how you decide to manage it.

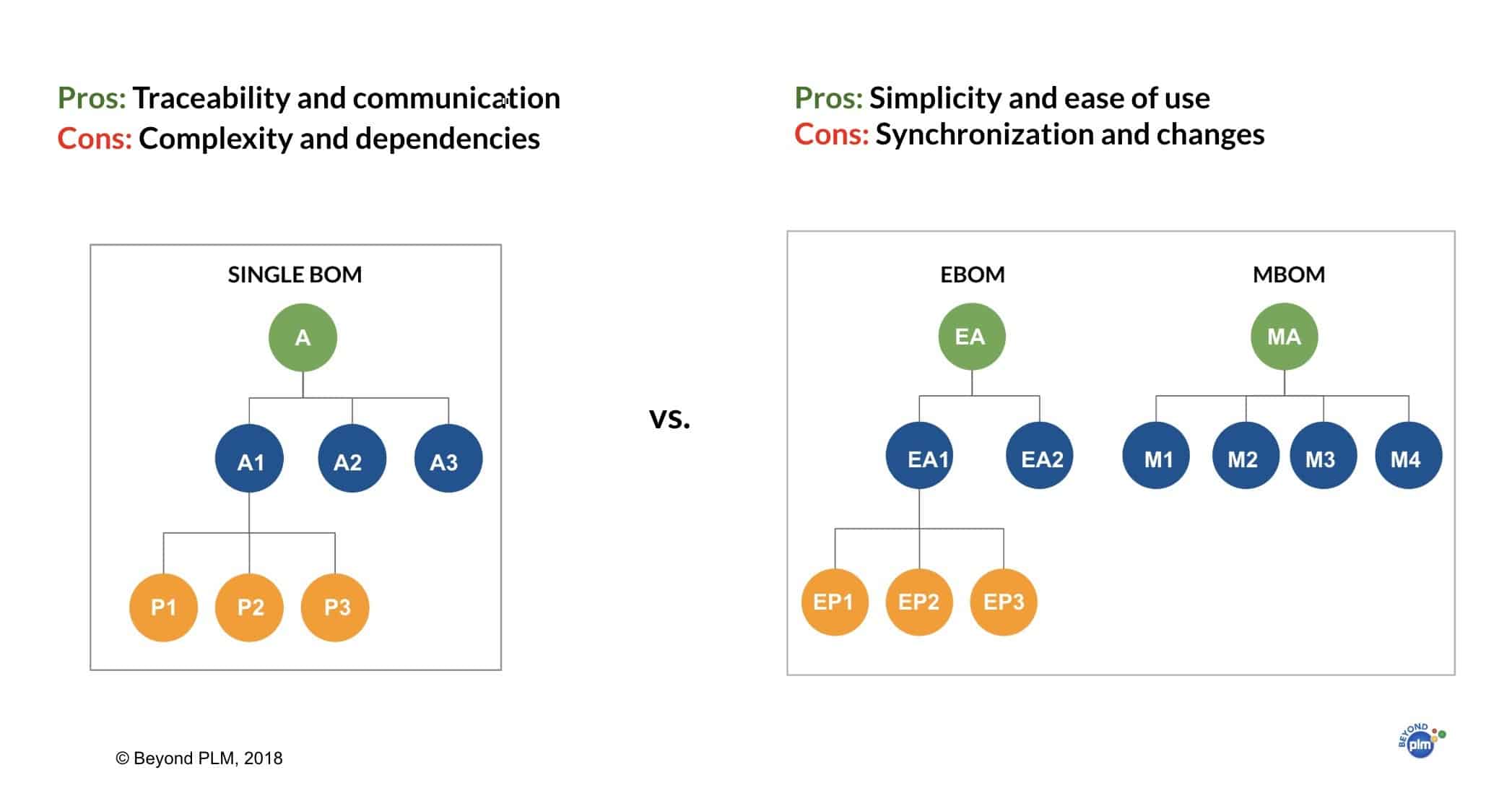

There are many reasons why a company would like to have two BOMs – EBOM and MBOM. The most obvious and important ones – these two structures can be really different, controlled by different people and therefore better be separated from each other.

At the same time, there are many good reasons why to have these two structures co-exist. Among many, I can point out the ability to have a single version of truth for the data, the ability to see data together and maybe even a better way to keep data in sync.

Historically, manufacturing companies were managing the Bill of Materials either by keeping it on the corkboards or storing them (later) in MRPII systems. Back in those days, it was no other BOM – engineers were working with the 2D CAD system, which technically was a drafting board. One of my favorite BOM management books – BOM for the lean enterprise by Dave Garwood will give you an idea of what is a single BOM. Introduction of 3D CAD systems and later PLM systems created another structure, which many companies started to call EBOM. There are tons or rational factors on why to keep this structure. This structure actually exists in 3D CAD, but then saved in PDM/PLM systems.

Last year, I created a video for my Beyond PLM blog describing both approaches, their pros, and cons.

Today, I want to give you a few ideas of how OpenBOM features can be utilized to manage both EBOM and MBOM regardless of what approach in EBOM/MBOM management you might have.

1- Structure (Parent-Child relationships)

OpenBOM gives you a simple, yet very powerful mechanism to create structures. You can derive structures from CAD systems and then you can adjust or modify it using OpenBOM editing features. Modification can be manually and also by copy BOM features

2- Single-level, Multi-level, Flattened BOMs

These three basic BOM types allow you to organize the data in hierarchical form, but also to provide an easy way to structure or flattened the information. The last one is the key when you need to push a flat BOM to manufacture and procurement planners.

3- User-defined views

OpenBOM user-defined views are like lenses that can be applied to the structure, but eliminating properties (columns), but also apply “filters”. By having these two mechanisms in place, you can think about organizing 2 structures that technically co-exist.

These three features of OpenBOM gives you a way to organize flexible management of data in both EBOM/MBOM as well as consolidated structures.

Currently, OpenBOM provides two out of the box mechanisms to manage EBOM and MBOM.

1- You can extract BOM from any CAD system (or systems) and organize it in the structure you might want to call EBOM (or BOM). The structure can be modified and OpenBOM will preserve the synch between CAD data and EBOM. The synchronization is completely automatic.

2- OpenBOM Order BOM is a way to plan purchases (procurement function). This BOM can be automatically generated from EBOM (BOM) and also OpenBOM will keep it in synch each time changes are made.

The automatic sync between BOM and Order BOM is a great way to keep engineers on the same page by helping them to separate the information. Although it is not prohibited, users can use a single BOM by including additional “manufacturing features” in the BOM created from CAD. Applying filters and view can help to differentiate between both EBOM and MBOM views.

Conclusion.

OpenBOM gives you a very flexible way to organize the information and manage both EBOM/MBOM as well as keep information centralized. The decision is yours, but some of the features will lean you towards one of the solutions. My recommendation to use BOM and Order BOM (including automatic sync). In addition to that, have a unified structure can be also beneficial.

In the next article, I will focus on the demonstration of both approaches using OpenBOM.

Check OpenBOM today – register to OpenBOM (Free) User Subscription.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.