Manufacturing companies continue to face mounting pressure: products are getting more complex, supply chains remain volatile, sustainability is no longer optional, and regulatory scrutiny is at an all-time high. Cost optimization is becoming critical. At the foundation of cost is the organization of bill of materials (aka product data).

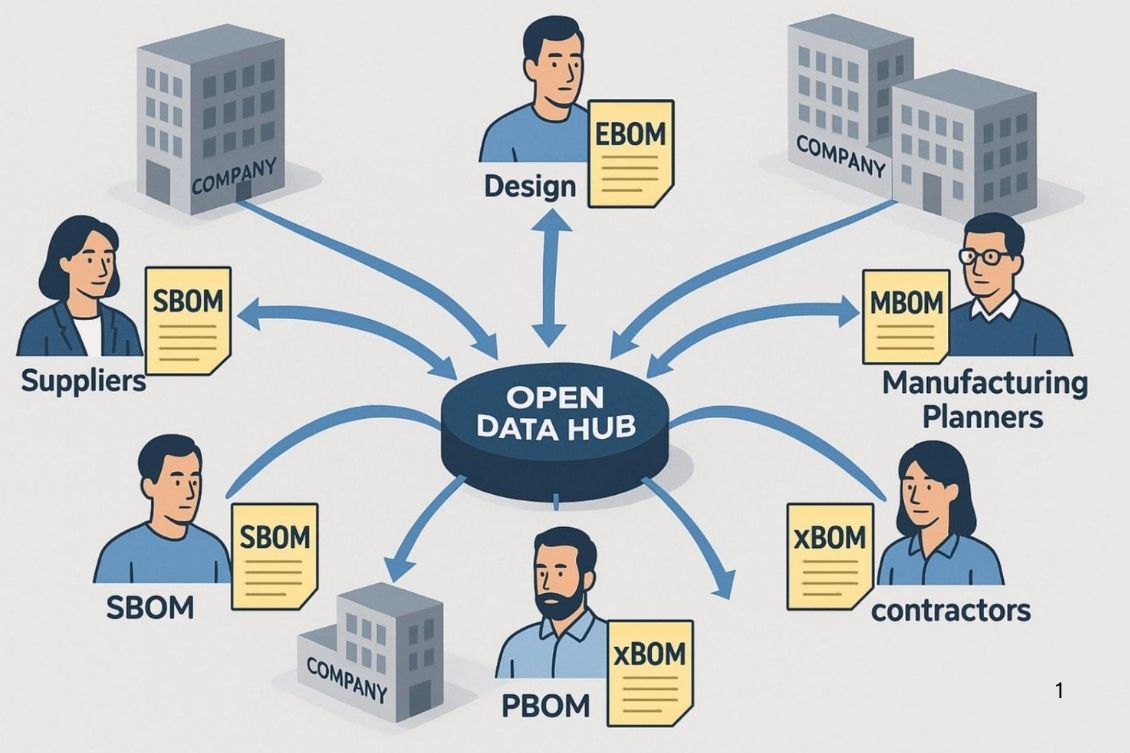

Historically, the data was thrown over the wall of manufacturing (dump CAD Excel to ERP) and engineering BOM was not significantly different from MBOM. These days, with suppliers, contractors, and factories, there are bigger differences between design, engineering, manufacturing, and factories.

Ten years ago, most Manufacturing BOMs (MBOMs) closely matched Engineering BOMs (EBOMs), but today, 65% of companies require MBOMs that differ significantly to meet specific production needs. Factory BOMs often vary 10–30% by site, reflecting local constraints and resources. Companies optimizing these differences report up to 15% cost savings by reducing errors and streamlining workflows. This shift underscores the need for a flexible, multi-view BOM system that supports various roles and processes across engineering, manufacturing, and supply chain.

This is why xBOM is becoming crucial. It’s about the xBOM—the extended Bill of Materials that includes multiple structures such as EBOM, MBOM, Factory BOMs, Service BOMs, and more. The xBOM is rapidly becoming the essential backbone of product development, manufacturing, and supply chain execution.

Why xBOM and why now?

So, why should engineering BOM, manufacturing BOM, maintenance BOM, factory, and other BOMs be top of mind for manufacturers in 2025? Here are five compelling reasons:

1. Digital Transformation Requires Data-Driven Infrastructure

Digital transformation isn’t just a buzzword—it’s a survival strategy. As companies modernize their operations with smart factory technologies, cloud-native tools, and AI-driven insights, a comprehensive and integrated xBOM becomes a foundational element.

An accurate, multi-view xBOM ensures that systems from engineering, planning, procurement, manufacturing, and service are all working from the same source of truth. This enables better coordination, fewer errors, and faster decision-making.

2. Supply Chain Resilience is a Must-Have

The fragility of global supply chains has become painfully obvious. From semiconductor shortages to geopolitical disruptions, manufacturers need to be proactive rather than reactive.

xBOMs give companies deep visibility into the materials, components, and suppliers that make up their products. With detailed data at hand, companies can quickly identify risks, source alternatives, and improve supply chain agility.

3. Sustainability Starts with the BOM

Sustainability is now a core requirement—not just a marketing differentiator. To drive real impact, companies must track the lifecycle of every material and component they use.

An xBOM helps organizations monitor environmental factors like material sourcing, energy consumption, recyclability, and carbon footprint—creating a digital thread that spans from design to end-of-life.

4. Product Complexity is the New Norm

Modern products are hybrids of hardware, software, and electronics, with increasing dependencies between physical and digital components. Think EVs, medical devices, robotics, or connected consumer goods.

To manage this complexity, companies need a BOM structure that goes beyond simple hierarchical lists. xBOM enables modular, multi-disciplinary design with clear visibility across mechanical, electrical, and software systems.

5. Regulatory Compliance Demands Traceability

As governments tighten regulations—particularly in industries like aerospace, defense, healthcare, and electronics—the ability to trace components, materials, and processes becomes mission-critical.

xBOMs provide the framework for compliance documentation, audit readiness, and product certification across global markets. With xBOM, you can ensure that you always know what’s in your product and where it came from.

What Do You Need to Support xBOM in 2025?

Ten years ago, the strategy was to “sync” data between siloed systems—PDM to PLM to ERP, using point-to-point integrations or custom middleware. That approach is no longer sufficient.

In 2025, the game has changed. You need a Digital Thread as a Service (DTaaS) platform—one that doesn’t just move data between systems but connects and consolidates it into a unified, open, and queryable format. Here’s what that infrastructure looks like:

- Open, federated data architecture: Eliminate data silos by supporting multiple data sources and BOM structures in real-time.

- Composable architecture: Let different teams and systems interact with product data without being locked into one vendor or monolithic platform.

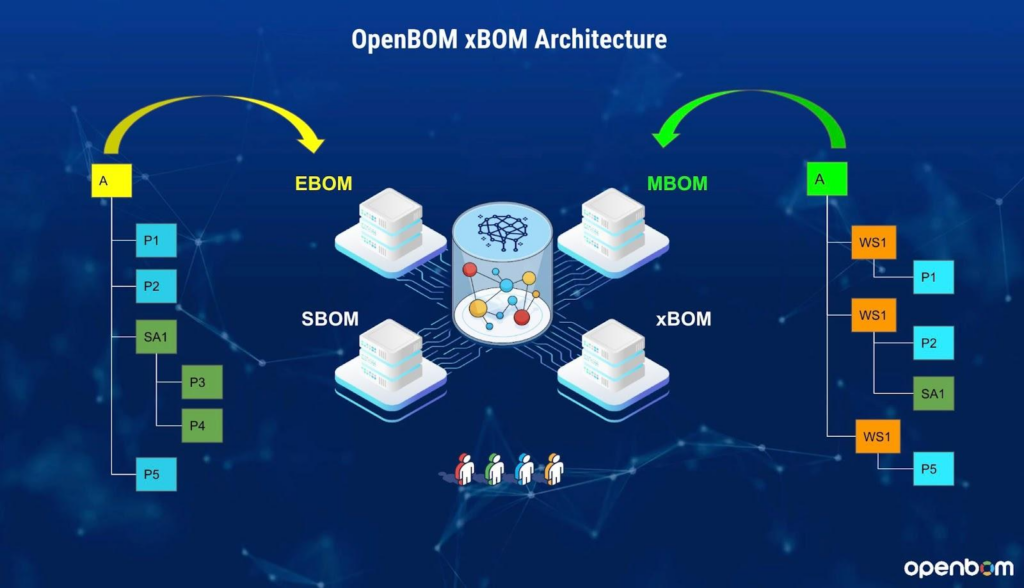

- Graph-based data modeling: You need scale, flexibility, and data science. Move beyond rigid tables and enable flexible relationships between parts, assemblies, processes, and documents. Brings data queries to support the complexity.

- Multi-tenant cloud-native platform: Enable scalability, collaboration across teams and partners, and easier maintenance.

- AI- and API-ready services: Make your data available for automation, analytics, and AI agents by using modern APIs and semantic access layers.

OpenBOM xBOM Architecture

I’d like to invite you to check OpenBOM xBOM architecture and to learn more about how OpenBOM’s graph-based multi-tenant architecture can support your xBOM efforts to seamless connection of design, engineering, manufacturing planning, and factory BOMs.

Conclusion and Final Thoughts

The next wave of manufacturing innovation relies on how well companies can manage and connect their product data. xBOM is no longer a “nice to have”—it’s the digital backbone of modern manufacturing. By investing in the right infrastructure now, you’re setting the stage for innovation, resilience, and agility in 2025 and beyond.

It’s time to move beyond syncing files and start building your future on connected, open data.

Interested in learning more about how OpenBOM supports open data sharing and connecting multiple applications – REGISTER FOR FREE and check it out.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.