Have you heard about Conway’s Law? I found it to be a very interesting and important topic for most product development and manufacturing organizations these days. Here is a general wording of Conway’s Law. It is named after computer programmer Melvin Conway, who introduced the idea in 1967. His original wording was: Any organization that designs a system (defined broadly) will produce a design whose structure is a copy of the organization’s communication structure. Read some of my thoughts about Conway’s Law and how it impacts product development and more specifically BOM management for each company here.

The Number of BOMs managed by Enterprise PLM will be equal to the number of organizations and sometimes teams involved in the design, production, maintenance, and support.

Here is how Conway’s law is coming into a play with product development. The time when product development was mostly dedicated by MCAD design is over. In the past, MCAD was the foundation of everything and therefore first PLM systems were heavily dependent on the MCAD role. But its time is coming to an end. We’re moving to systems combined by multiple disciplines.

System Lifecycle Management and Multi-Disciplinary Collaboration

Back in the days of early PLM, MCAD was a dominant force, but these days product development is shifting towards a broader recognition of the importance of systems in product development. In my earlier article System Lifecycle Management, I reviewed modern approaches developed by researchers working on what is the next step for PLM. The biggest challenge of System Lifecycle Management remains the same – organization of information flows and data interoperability. Companies, products, and services are getting more connected. But the same cannot be said about PLM tool developments. The openness and interoperability between the tools is the key to make the PLM industry move to a system lifecycle approach.

So, what can be done to create a foundation for information interoperability and streamline information flow and data sharing? At OpenBOM we take data collaboration to the next level by developing a set of tools and technologies to bring data from multiple sources (design silos) and combine it together. Multiplied by the OpenBOM collaboration tool, it is a foundation for new multi-disciplinary product structures and design collaboration.

Here are 3 elements of OpenBOM technology that enable such collaboration.

Flexible Data Model

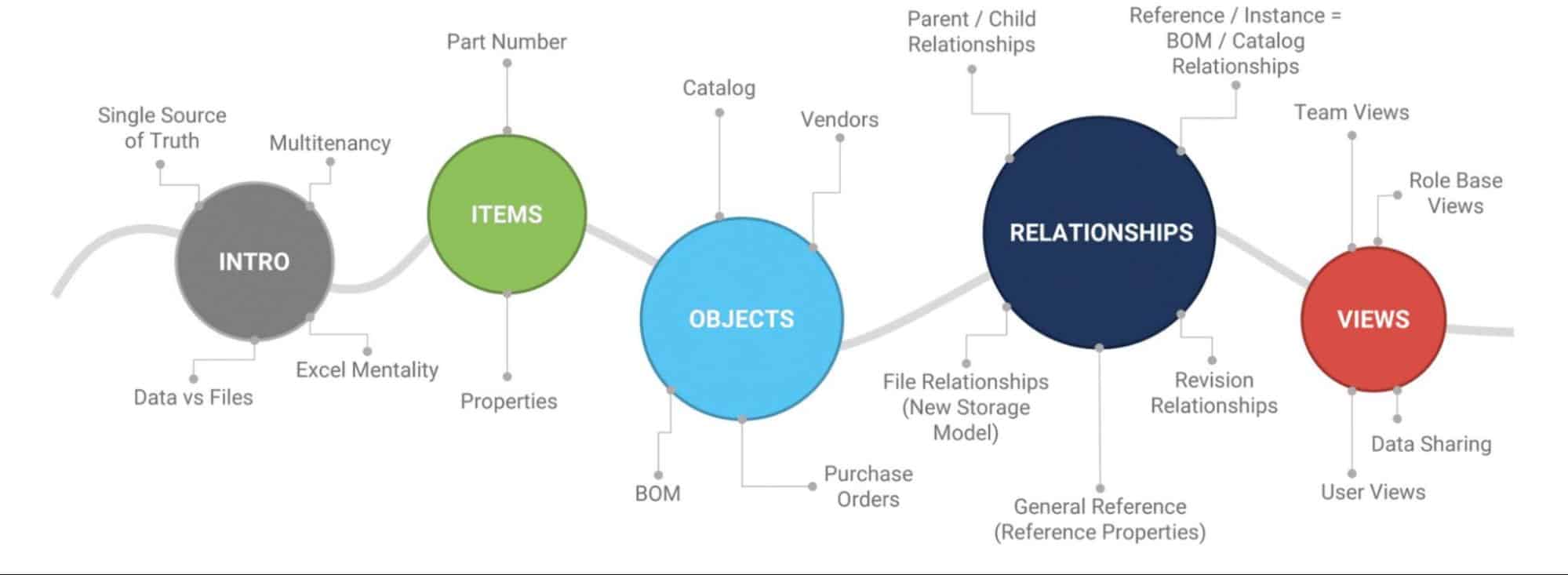

The foundation of OpenBOM is a flexible, multidisciplinary, and dynamic data model capable of holding the data about the product, each siloed data source, and connect it together in the most flexible way. You can learn more about OpenBOM Data Model in OpenBOM Training Library – Data Management.

Integration with design tools (MCAD, ECAD, PCB, etc.)

Data is a key element in every product development process. Acquiring the data is a key element of each data management and collaboration tool. Manual data import is very inefficient and the product development process relies on many data sources. The major data sources are coming from CAD tools (MCAD, ECAD, PCB, etc.). OpenBOM provides integration with many CAD tools – check out more information on the OpenBOM website integration page.

Real-time BOM collaboration tools

Tools that allow people to collaborate is the third element to facilitate design collaboration and product engineering. OpenBOM developed unique patented methods of helping people to collaborate in BOM management and product development. Check out more about OpenBOM BOM Collaboration Patent Award and how it helps engineers working on different systems in the product to coordinate and work together using OpenBOM.

Watch this video to learn more about OpenBOM’s Data Sharing and Collaboration.

Conclusion

OpenBOM provides a set of tools and technologies that can connect people in the organization regardless of their roles, functions, and responsibilities. The foundation of this connection is product data. OpenBOM’s flexible data model and patented collaboration tools allow creating a data representation of the product that can be dynamically shared between multiple people in the organization responsible for different aspects of the product development (mechanical, electronic, PCB, software).

The data connecting people serves as a collaborative middle-ground to connect everyone’s activities to streamline product development and other related activities. Seamless integration with MCAD, ECAD, PCB, and other tools is a foundation of this process.

Check out what OpenBOM can do for you today. REGISTER FOR FREE and start a 14-day trial of all our features.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.