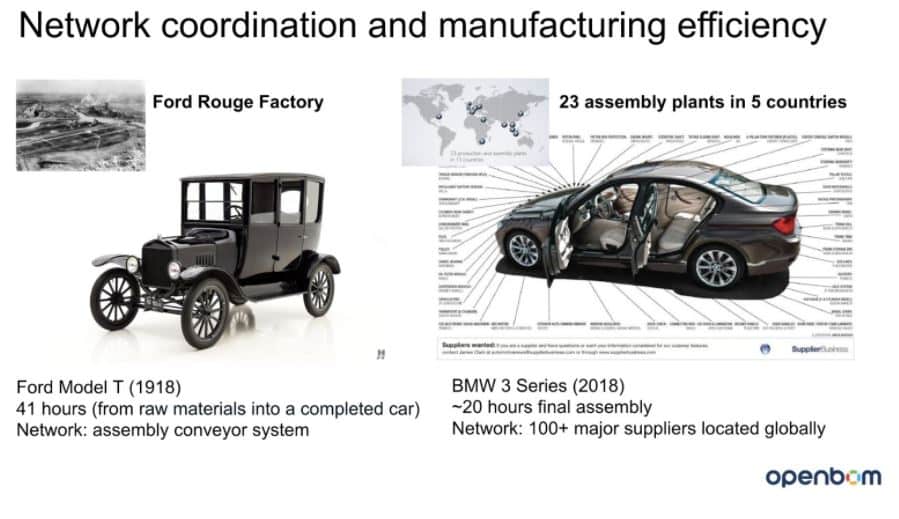

The manufacturing industry is in dire need of new technology to enable better connectivity between users and companies.

Times have changed and the tools used in the production process need to reflect these changes. Modern companies are working out of multiple locations and are working directly with an extensive network of suppliers and contractors.

Such an environment creates a tremendous challenge for manufacturing companies to solve their global collaboration problems. Check this picture out to see how different manufacturing companies are now compared to those companies that we’ve seen in the past. This is the reality of modern manufacturing.

What Makes OpenBOM Different?

Data management, data sharing, and collaboration are the three fundamental parts of OpenBOM technology that differentiate it from many other systems.

The foundation of OpenBOM is a multi-tenant data management system built on top of modern cloud computing microservice architecture capable of scaling and providing global service to companies worldwide.

This data management architecture provides a flexible data backbone and also builds a network of companies, contractors, and suppliers working together.

OpenBOM supports instant data sharing with a flexible user-defined dynamic view (Team View), so every user, team, contractor, or supplier will have access to the portion of the data they are supposed to see.

The third element is simultaneous real-time collaboration, which allows multiple users in different companies to work together and perform changes based on a set of rules and restrictions.

What’s The New OpenBOM U.S. Patent About?

We are happy to share that the United States Patent and Trademark Office has issued a patent, covering a system and method for a collaborative bill of materials management.

The Invention (US Patent No. 11,037,103) enables collaborative BOM management using data architecture and communication technologies between people and companies, which is changing the way companies can work together in this modern product development and manufacturing environment.

The majority of existing PLM and BOM management software was developed for a single company without even thinking about how companies can work together and organize the networks. New technologies and network-based global collaboration platforms are absolutely necessary for future innovation in product design and manufacturing.

Inside Look On Companies That Have Found What They Needed With OpenBOM

Here are a few examples of companies and use cases that are relying on OpenBOM to bring their collaboration and product development process to the next level.

A Fortune 500 Global Electronic Manufacturing company is using OpenBOM to accelerate their new product development and connect engineers, procurement teams, and manufacturing planners. Here is how the head of the engineering team describes the advantages of OpenBOM and its collaborative functions:

The existing legacy PLM environment is too complex and too costly, cannot deliver an easy model to collaborate, and fails to provide an agile environment for production planning, which is typically handled by a super sophisticated corporate ERP system.

For agile new product development, these two existing systems (PLM and ERP) were like a heavyweight that was slowing the NPD process down.

And here is a huge time saver…

“This time last year I personally spent 5 hours per week on BOM maintenance. It’s now 10 minutes a week. We see that same improvement with many of the lead engineers on the team. OpenBOM frees the team to do the other things that are important.”

FF Robotics is developing a super-intelligent artificial intelligent robot capable of picking a better apple (or any other fruit) from the tree and placing it in the container in a fully automatic way. FF Robotics started to use OpenBOM to solve their data management problem to manage 16K parts in their machine. However, a huge unexpected value was collaboration. Check the user story on our website. Here is a passage.

“Something we didn’t anticipate was the ease of sharing the BOM with the rest of our team. We have a property for Make or Buy which we set in the Catalog. FF Robotics purchasing department gets the BOM and knows exactly what to do. We could have done it before but it demanded more work and sometimes it just didn’t get done or we made some mistakes.”

Conclusion

The industry is moving towards better connectivity, communication, and collaboration. The proper data management and collaboration tool is the foundation of this new connected manufacturing world. OpenBOM innovation makes communication and collaboration easy.

Check OpenBOM today – REGISTER for FREE and start your 14-day trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.