In this video, I explain the basics of the OpenBOM purchasing process. Check out our website to learn more about RFQ and Purchasing.

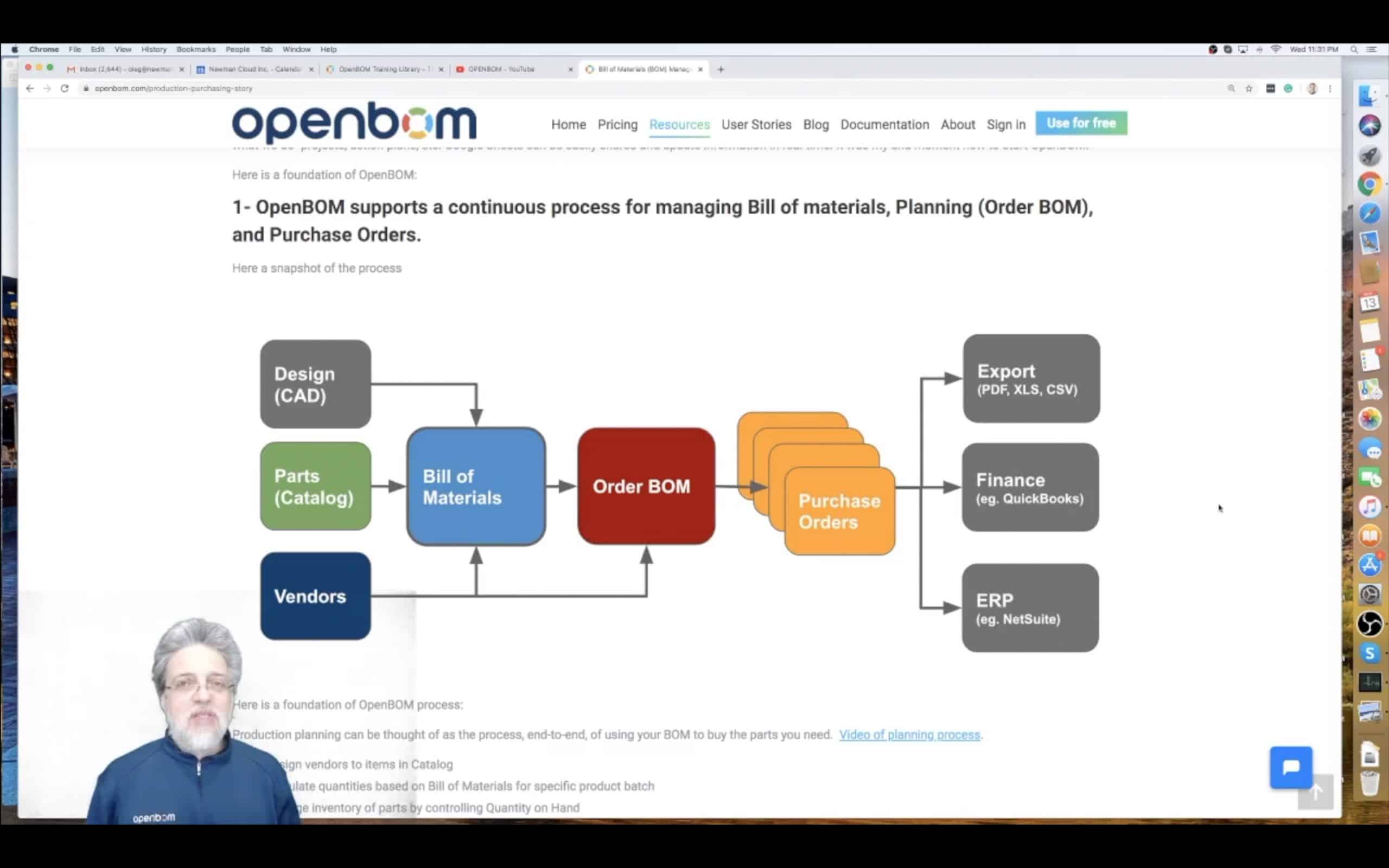

OpenBOM helps to connect design and purchasing and streamline the process of ordering based on accurate product information. There are 3 main inputs in the purchasing process (1) Design; (2) Catalog and (3) Vendor lists. OpenBOM connects them together and creates a Bill of Materials, which contains information about all parts and assemblies that need to be purchased.

Order BOM is a central element of purchasing or RFQ process. It is a shopping list scaled to the number of units you need to order.

And there is the video:

Conclusion

Bill of Materials is a tool to support the purchasing process. Without the Bill of Materials, an organization cannot fulfill the process of purchasing. BOM contains information about parts, correct description, manufacturers, packaging, suppliers, cost, and many others. Order BOM produced from the Bill of Materials, scaled to the number of units is a foundation of RFQ and purchasing. POs can be generated automatically at any time and can be sent via email or automatically transferred to financial applications such as QuickBooks. PO can be also exported to Excel or PDF format to include your company logo and additional supplier or contractor information.

Give it a try. Check OpenBOM now by registering an account here.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.