In this video today, I want to talk about the fundamental elements of the Bill of Materials data model and how to manage it in OpenBOM.

There are 2 main elements of BOM model:

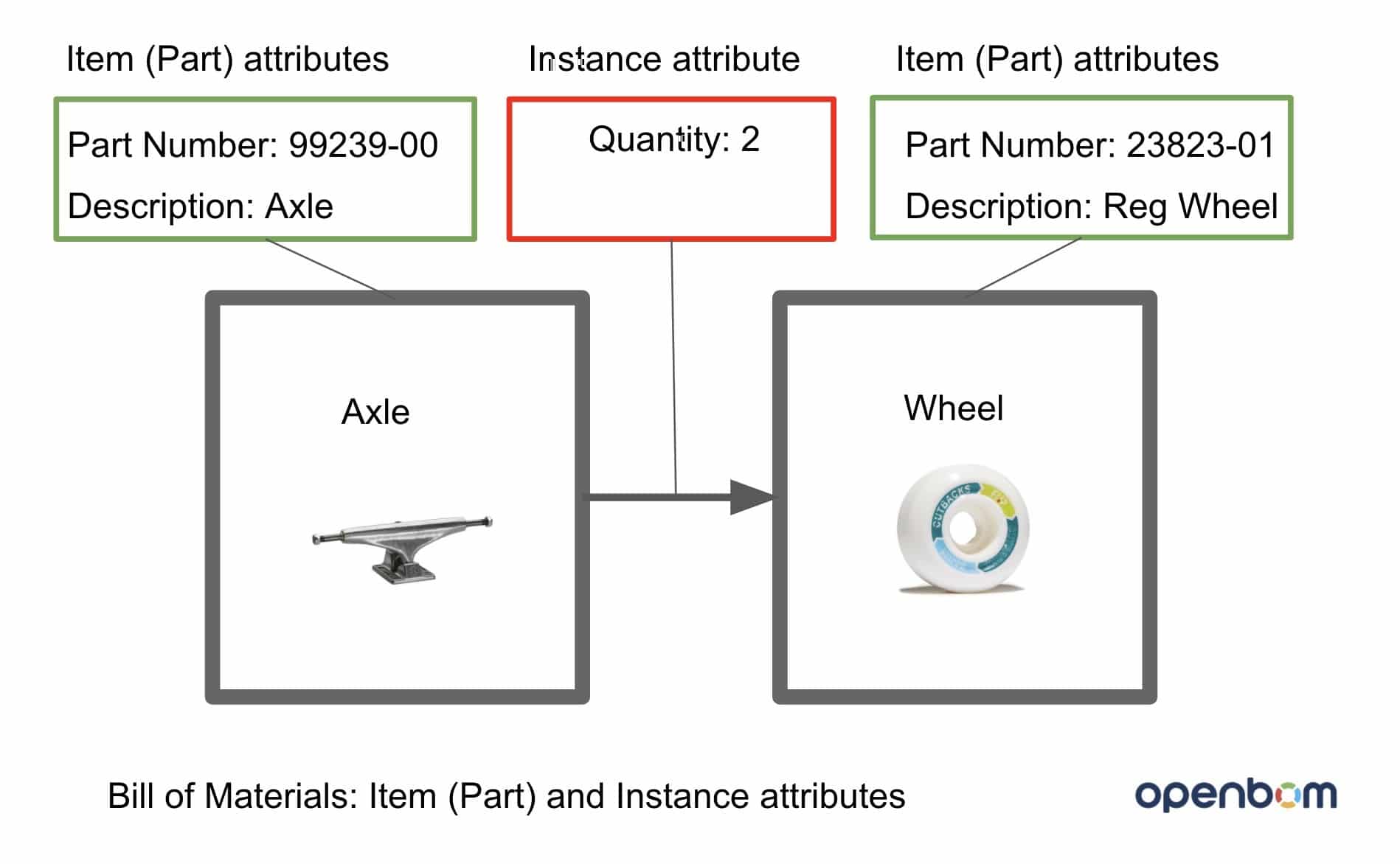

- Part (contains information about an abstract part including all attributes such as Part Number, Description, Manufacturer, Cost, Supplier, etc.) It is essential to have it in a single place centralized. Otherwise, you will have the same problem as you might experiencing with Excel when you forced to copy it from Excel to Excel).

- Part Instance (contains information about specific instances of the Part in a BOM). In such a case if I create an instance of the Part, the information about Part will be referenced from a single location, and information about the instance will be variable for each instance.

Check out the diagram below to get an idea of what I’m talking about.

At OpenBOM, we allow managing both part and instance information in the most flexible form. You can add any property (attribute) to a catalog. Any number of properties can be added at any time. Instance information is managed in BOM(s) and we can always add properties there to create “instance” properties.

Watch the video

Conclusion

OpenBOM gives you a flexibility to customize parts and part instance information on a granular level by defining properties for parts (in catalogs) and instances (in BOMs). In such a way, OpenBOM gives you the power to create the most sophisticated data models for products you’re developing.

Check OpenBOM now by registering an account here.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.