In modern manufacturing, tracking data is more critical than ever. From virtual engineering to physical information captured from products in the field, having a robust system to manage and trace data is essential. OpenBOM’s powerful xBOM architecture enables you to seamlessly manage engineering, manufacturing, support, and maintenance data by connecting multiple data sources and systems.

How OpenBOM Does It

OpenBOM’s powerful capabilities for tracing physical information lie in three key features: its flexible data model, integration capabilities, and calculated properties. These features empower manufacturers to organize, capture, and analyze data across the entire product lifecycle, ensuring traceability and optimization at every stage.

Flexible Data Model

OpenBOM’s flexible data model is at the core of its capability to manage diverse product information. This model allows you to:

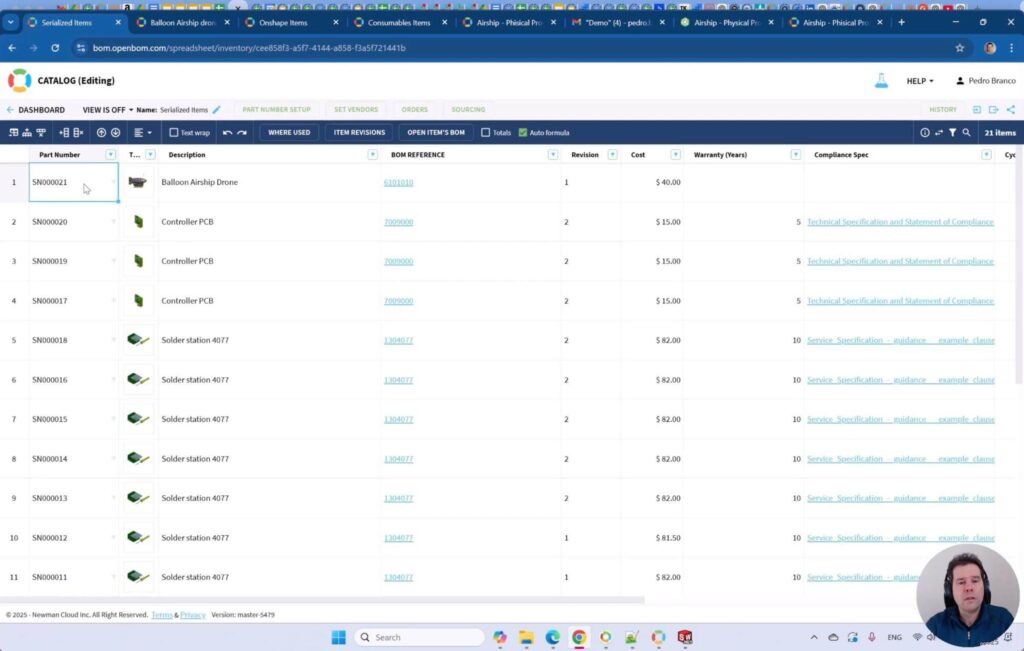

- Define Multiple Item Types: Whether it’s engineering items during the design phase or serialized product items for maintenance and field operations, OpenBOM’s data model supports the creation and organization of distinct item types.

- Create Multiple BOMs: Using OpenBOM’s xBOM architecture, you can generate various Bill of Materials (BOM) types to suit specific needs, such as:

- Engineering BOMs for product design and development.

- Maintenance BOMs for post-sales support and field operations.

Import Functions

To ensure seamless data capture, OpenBOM provides robust import capabilities. These include:

- Manual Entry: For quick and straightforward data entry.

- API Integration: To automate the capture of data from various systems and sources, including CAD, ERP, and IoT platforms.

These import functions make it easy to aggregate data from disparate sources, providing a comprehensive view of both virtual and physical product information.

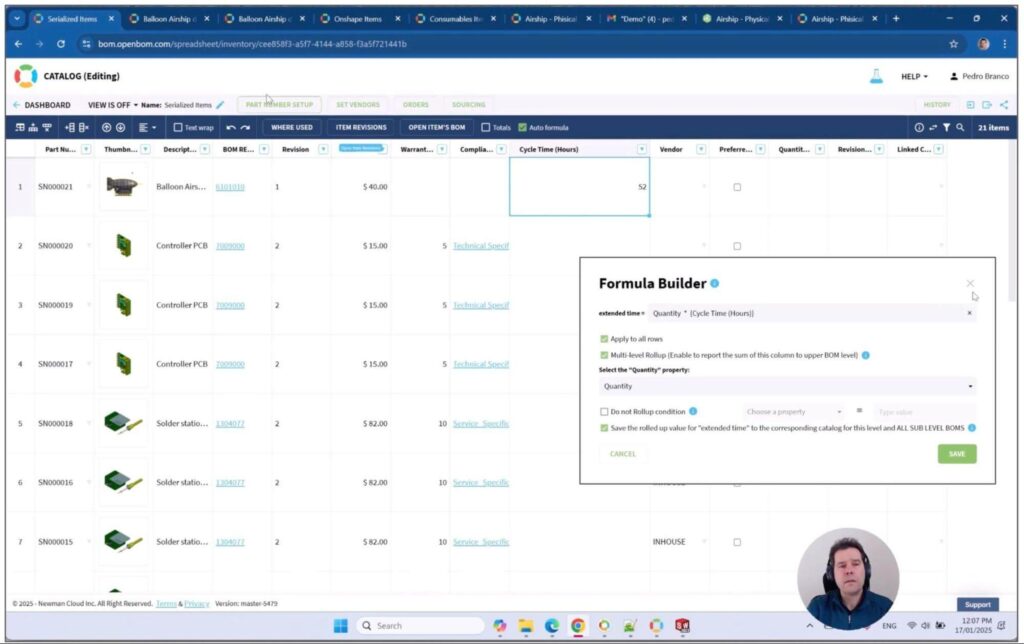

Calculated Properties

Calculated properties in OpenBOM take data management to the next level by automating data aggregation and rollups. This feature enables you to:

- Roll Up Specific BOM Data: Automatically calculate and consolidate information for all BOM types, ensuring accuracy and consistency across engineering and maintenance data.

- Track S/N and P/N Data: Maintain traceability for serialized and part-numbered components, crucial for maintenance and customer-focused operations.

Video: Managing Drone Flight Time Data

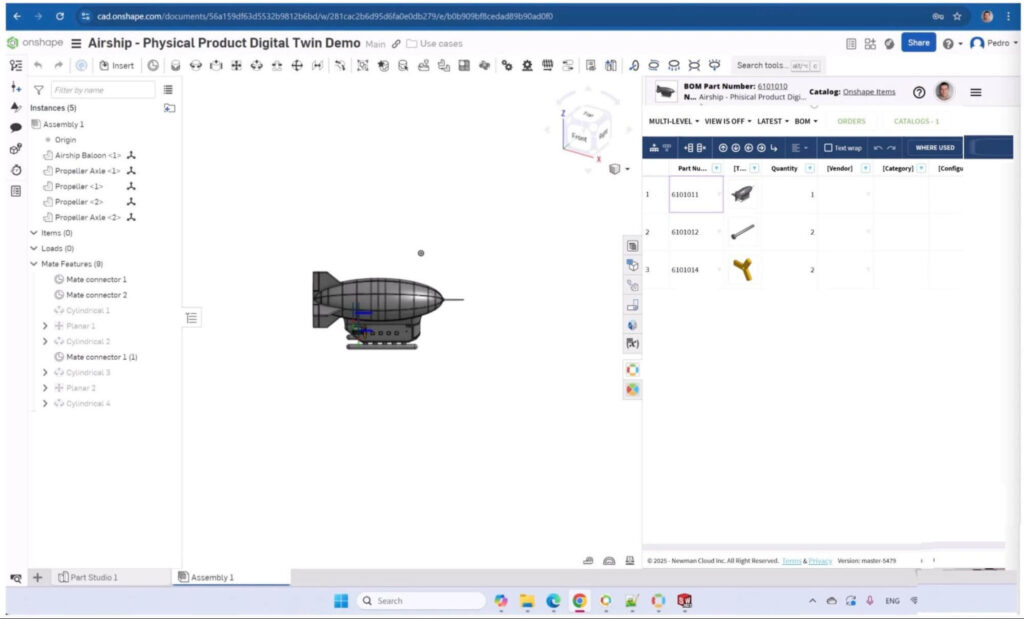

In the accompanying video, we demonstrate how OpenBOM’s flexible PLM data model facilitates the capture and management of physical information using the example of a drone.

This includes tracing serialized components, creating maintenance BOMs, and utilizing calculated properties to streamline data management. Imagine extending these capabilities to complex products like vehicles, high-tech devices, or medical equipment!

Conclusion

OpenBOM’s robust data management infrastructure provides the tools needed to organize and capture diverse information types throughout the lifecycle of a product. By seamlessly integrating engineering and operational data, OpenBOM enables manufacturers to manage maintenance BOMs and ensure traceability with engineering data—an increasingly critical aspect of optimizing product development and enhancing customer-focused business processes.

Watch the video to see how OpenBOM can transform your data management practices and drive efficiency in tracing physical information from engineering to field operations.

REGISTER FOR FREE and check how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.