One step of the manufacturing process is negotiating specific terms with your contract manufacturer (CM). When your CM sends you a contract or a quote with terms, you don’t always need to take it for what it is. You can negotiate with them.

Here are the 4 main parts that should be negotiated with your CM.

MOQ

When you first launch your product, you will not have large orders. You will want to slowly roll it out instead of ordering too much and spending money on holding inventory. Sometimes a CM will try to squeeze a bit more out of you and force you into ordering more than you need. They tell you that it will get you a lower cost/unit to convince you, but usually, this can be negotiated.

If the MOQ is too high then you can negotiate in two ways. First, you can negotiate a lower MOQ for this order and for all future orders. Or, secondly, you can negotiate a lower MOQ for just the first order. If your CM has some flexibility, they will allow you to order the first order with a lower MOQ at the same cost as the original MOQ. You just need to make sure you can have larger POs in the future.

Access to their Engineering and Technical Team

One of the biggest values of a CM is their value-added services, such as design for manufacturing (DFM). This is when the CM is able to take the product data from the manufacturer and turn it into something that can be replicated at high volumes, with low-quality defects, and at an affordable price.

The CM will support you to analyze each part and all of the processes that are dependent on that part, such as tooling. If your CM is not able to provide you with engineering support then they might not be the best fit for you.

Another reason access to their engineering team is important is that quality issues will come up. A CM without a technical team will not be able to solve and develop the root cause for these quality problems.

Payment Terms

The term most commonly negotiated with the CM is the payment terms. The goal of improving payment terms is to improve your manufacturing business financials.

Usually to establish favorable payment terms with a supplier you will need to have a positive credit history. On the first order of your new product, obtaining NET30 is most likely impossible. The common journey to develop favorable payment terms looks like this:

First Few Orders:

- Downpayment of 50% paid upon placing the PO

- Balance of 50% paid before shipment

After some trust is built

- Downpayment: 30%

- Additional deposit of 50% paid before shipping

- The final balance of 20% 30 days after shipment

The final goal is to have no downpayment but this takes time and credibility.

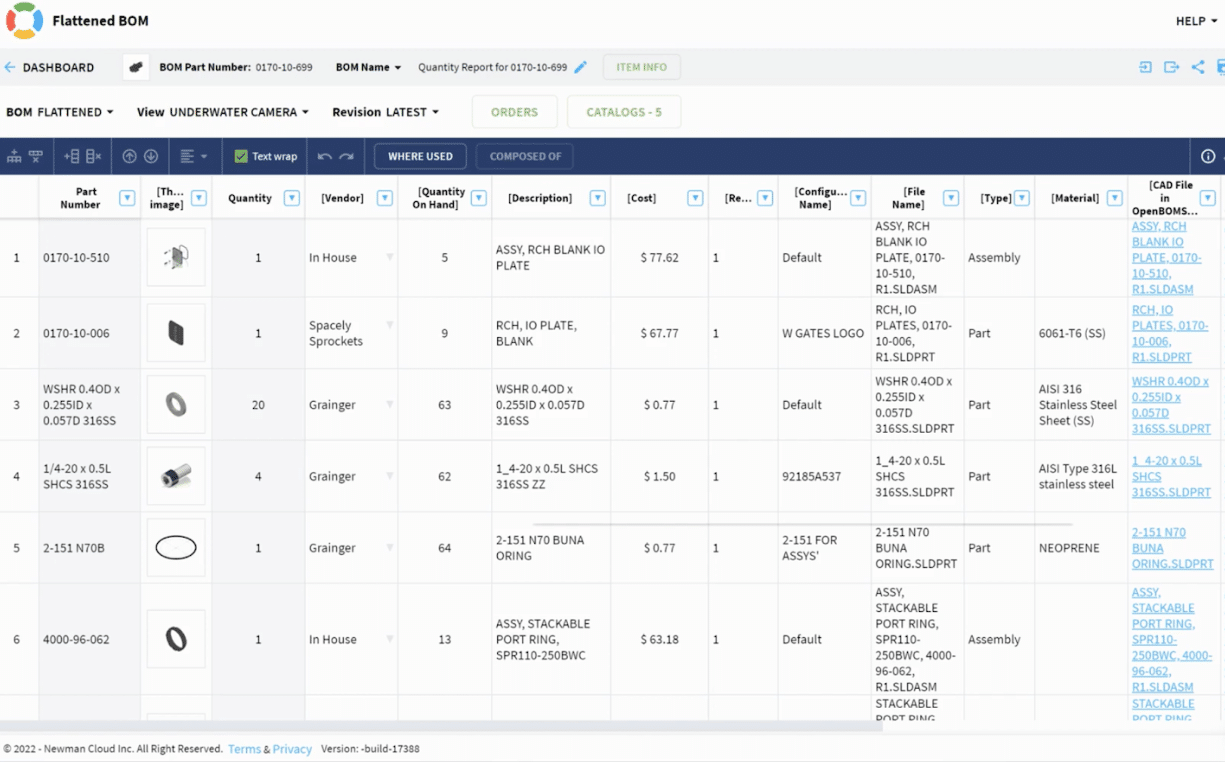

Pricing Through a Full BOM Quote

Your CM will provide you with your production costs in 2 ways. They will either give you one number that is for the full product, or they will break the cost down so you have a full BOM quote. The second option means that you have a quote for each individual line item on the BOM, including all of the parts, labor, quality control, and more. See the picture below as a reference.

Not having a full BOM quote will not provide you with the transparency you need in order to know the pricing structure. Having a full BOM quote will also help you to start any cost-down projects as well. You should also try to get a full BOM quote.

How Can OpenBOM Help?

OpenBOM improves the process of how you work with your CM, contractors, colleagues, and other team members. We provide you with the capabilities to seamlessly manage your parts, vendors, bill of materials, purchase orders, and change orders. All BOM, engineering, and manufacturing information is stored in the cloud which you can share with anyone.

If you need to improve the way you manage your data and processes, contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.