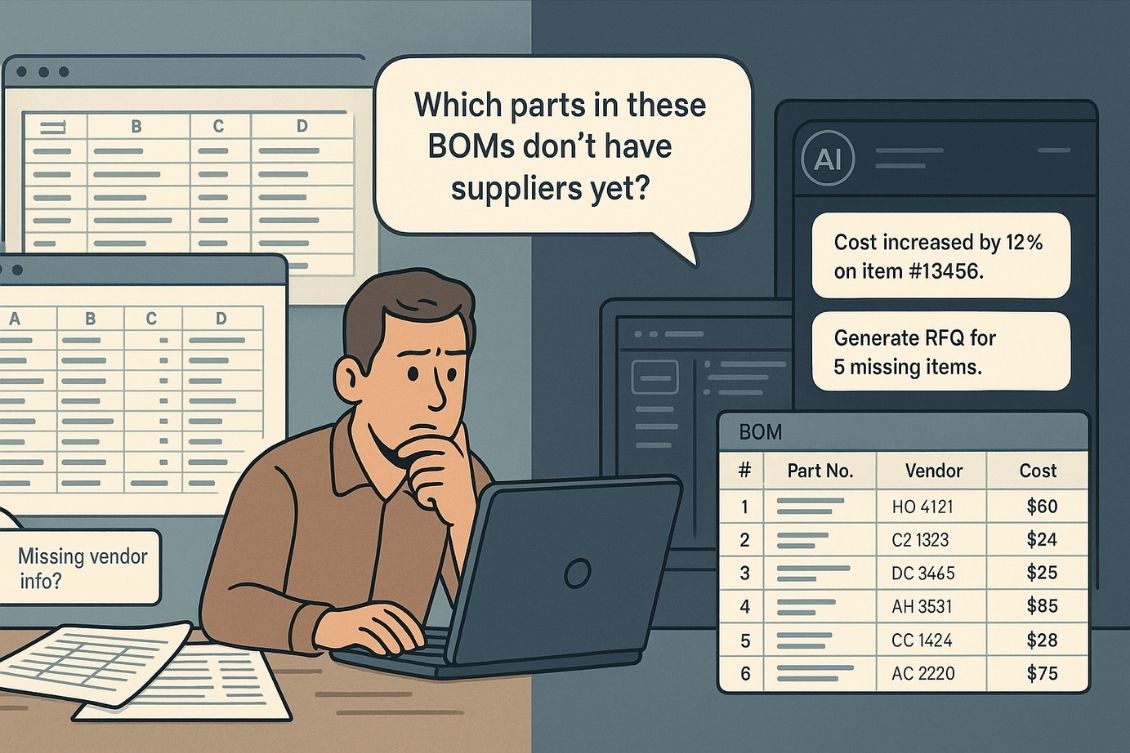

You’re staring at three BOMs – Excel sheets from different engineers. The formatting is inconsistent. Part numbers and columns don’t align. And your inbox just pinged with a fourth quote that’s zipped with PDFs and marked “Final_v3_MayUseThisOne.zip.”

The clock is ticking. You need to finalize an RFQ package, compare costs, select preferred vendors, and prepare internal approvals—all before your suppliers start disappearing for the holidays.

If you’ve worked in procurement or cost engineering, you’ve been here. It’s not about design anymore. It’s about chasing files, translating formats, stitching spreadsheets, and trying to make sense of fragmented sourcing data across disconnected systems.

But what if you could just… ask an agent to do this work for you?

“Which parts in these files have the highest cost delta across suppliers?”

“Are any of these vendors not approved?”

“Can you generate an RFQ draft for the missing components?”

And you get real answers—instantly.

That’s what happens when product data becomes memory—and that memory talks back.

The Procurement Puzzle (Without the Puzzle)

Traditionally, cost analysis and RFQ workflows meant juggling systems: PLM for product BOM structure, ERP for vendors, spreadsheets for pricing, and email for communication. Every task—no matter how small—required a context switch.

Find the part. Match the revision. Check the vendor status. Copy to Excel. Get STEP and Drawing files. Clean the data. Compare quotes. Build a cost breakdown. Then start a new round of emails.

With OpenBOM AI Agent, we plan to connect these pieces together.

Drop in a BOM and say, “Compare this with last year’s pricing and highlight increases over 10%.” (similar to how you compare bills for your cellular phone bill)

Or, “Which of these parts have no supplier assigned yet?”

You’re not building a pivot table. You’re starting a conversation.

Talk to the RFQ Process Like It’s a Person

With OpenBOM’s conversational model, procurement and sourcing professionals don’t have to learn new systems or navigate hidden menus. You interact the same way you talk to a colleague:

“What’s the total estimated cost for this assembly based on current supplier pricing?”

“Who quoted this motor in the last cycle?”

“Are any of these suppliers on hold or flagged for late deliveries?”

The Agent understands the files, matches the vendors, tracks the history, and gives you a clear response—with supporting detail, not just a number.

You can then follow up:

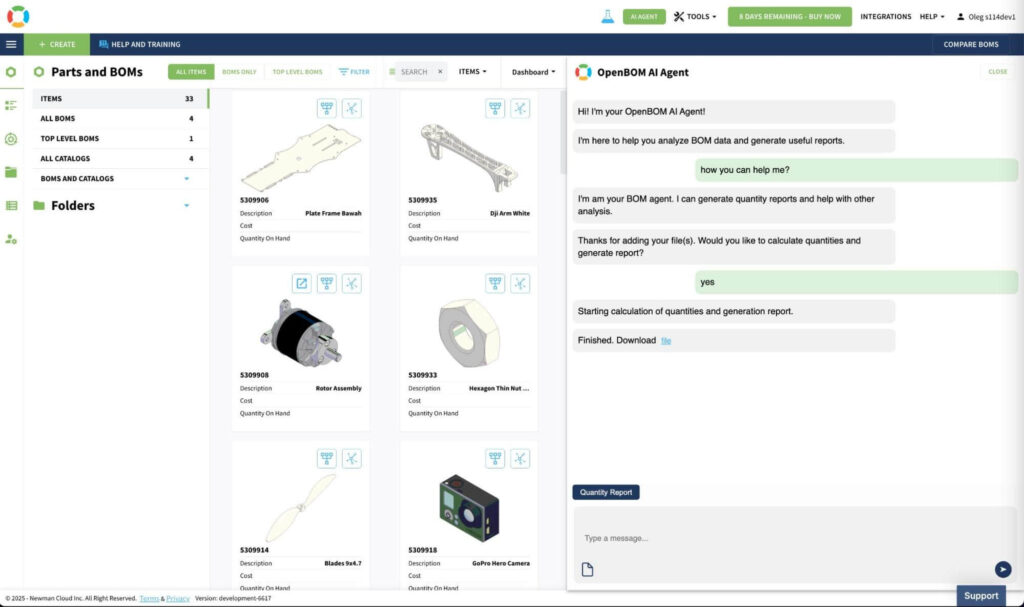

“Create a quantity report for procurement”

“Generate a cost report by the supplier.”

“Create an RFQ template for the five unquoted items.”

“Add Steve from purchasing and share the summary.”

No switching systems. No exporting. Just a natural flow of decisions supported by conversation.

Cost Data That Understands Context

Let’s say you’re reviewing sourcing options for a critical subassembly.

You ask the Agent: “What’s the cheapest vendor combination that meets delivery requirements?”

It responds with three scenarios: lowest cost, fastest lead time, and balanced value. It even flags a supplier that historically missed shipments and highlights a part with volatile pricing.

Or you ask: “What changed since our last cost estimate?”

The Agent replies: “Four items increased in price—two due to vendor switches, and one due to material change. One new item added.”

This is cost analysis, not as a report—but as a conversation. One that understands the story behind the numbers.

The Memory Behind Every Quote

Imagine asking:

“Why didn’t we go with Supplier B last time?”

The Agent recalls the 2023 sourcing round. It pulls up the RFQ notes, reminds you that Supplier B failed to meet packaging specs, and shows the vendor review summary with procurement’s feedback.

That’s not just data retrieval—it’s organizational memory surfaced in seconds.

When sourcing is this contextual, you make decisions faster—and with more confidence.

From BOM to Action in One Conversation

Let’s walk through a common workflow.

You upload three Excel BOMs from different subcontractors. Formats vary. Some have cost, some don’t. You say:

“Create a unified BOM and flag duplicates.”

Seconds later, it’s ready.

You follow up: “Add vendor info from our approved list and estimate total cost.”

The Agent cross-references your vendor catalog, matches parts, and fills in pricing.

Then: “Generate an RFQ document with items still missing pricing and attach supplier part numbers.”

Done.

Finally: “Send to procurement and add last year’s pricing as a reference.”

It’s one continuous interaction—no dashboard configuration, no exporting to Word, no juggling files.

Just questions and actions, seamlessly connected.

Beyond Intelligence: Operational Velocity

This is what changes when you combine conversational input with structured product and sourcing data.

Procurement no longer operates downstream from engineering. Cost analysis is no longer static. RFQs aren’t cobbled together in spreadsheets.

You’re not reacting. You’re orchestrating.

And every answer the Agent gives you is built on:

- Structured product models that understand BOMs, revisions, and suppliers

- Contextual memory that tracks past decisions, vendor history, and pricing

- A conversational interface that eliminates friction and respects how teams actually work

This is more than automation. It’s augmentation.

Conclusion

The complexity of product development, engineering, manufacturing and procurement tools is growing these days. These teams are buried under tools they didn’t choose, processes they didn’t design, and data they don’t fully trust.

At OpenBOM, we want to change the way data and process is orchestrated by building a product memory that can be used contextually together with the process. The OpenBOM AI agent will help you to make the product memory to speak. Now you can ask what matters:

- What are the three most critical suppliers

- What components are still not delivered

- Why did we decide to change the supplier for this component

The system will use the memory to assist you with these answers..

Because product data isn’t just documentation—it’s a digital memory of your organization and context to produce an intelligent prompt for the results. experience. It is an approach to unlock the new way of managing product information and engineering workflows.

Interested to learn more about what we do? REGISTER FOR FREE and check with our support team.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.