In today’s business environment, the pressure is on manufacturers to optimize the supply chain and keep production levels growing. One way to increase efficiency and reduce costs is to multi-source strategic items in the supply chain. By carefully evaluating supplier capabilities and cost structures, manufacturers can improve their overall competitiveness. In this blog post, I will talk about important OpenBOM enhancements that will bring new advanced capabilities to manage components sourcing.

Business Process – Design To Purchasing

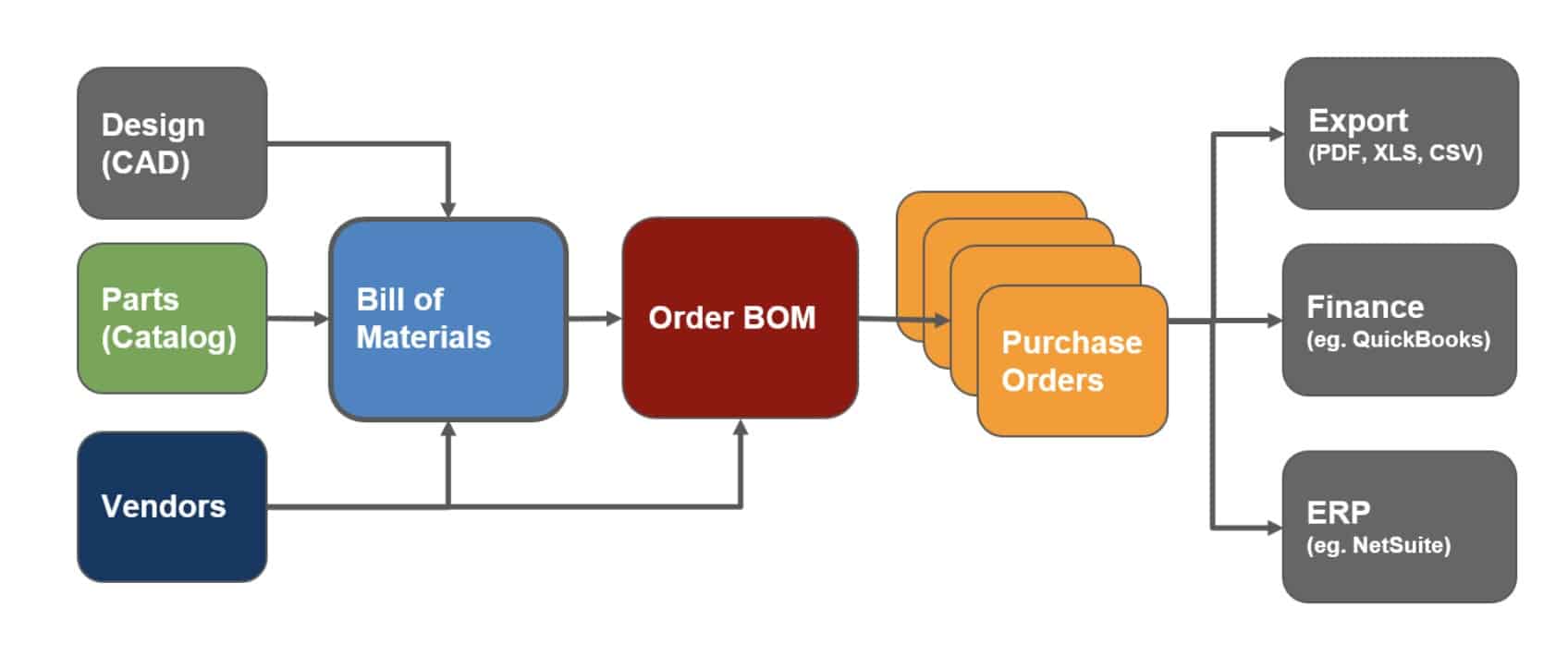

A very unique capability of OpenBOM is an integrated process covering the information flow, data management and transactions from design and engineering to order planning and purchasing. OpenBOM provides immersive integrations with design and engineering (CAD) environments, provides rich engineering Bill of Materials management capabilities, and provides support for inventory management, vendor management, and purchasing/procurement functions.

In the picture above you can see a schematic of the business process supported by OpenBOM allowing management items, vendors, CAD, Bill of Materials, Orders, and POs. Having all these functions fully integrated with a cloud-native collaborative environment provides a huge value to industrial companies, especially in SMB/SME segments for manufacturing and engineering teams with limited IT resources and significant pressure to deliver products in the realities of a global manufacturing environment.

Multi-sourcing for parts and components

An ability to procure from multiple sources is an extremely important function of business systems and we’ve been getting many requests recently to improve it. The reason is very simple – companies are struggling to source components and they need to have a robust and flexible mechanism to manage their supply chain relationships.

Earlier last week, I provided a sneak peek of the new OpenBOM partial PO receive mechanism, which is one element of OpenBOM improvement for the purchasing process. The second part is multi-sourcing support.

The new enhancements will be focused on the improvement of the OpenBOM data model and new user experience for sourcing flyout and sourcing objects. The significance of data modeling enhancements goes much further than sourcing because it introduces new relationship types between objects in OpenBOM that will be used in many new features we plan to bring later this year.

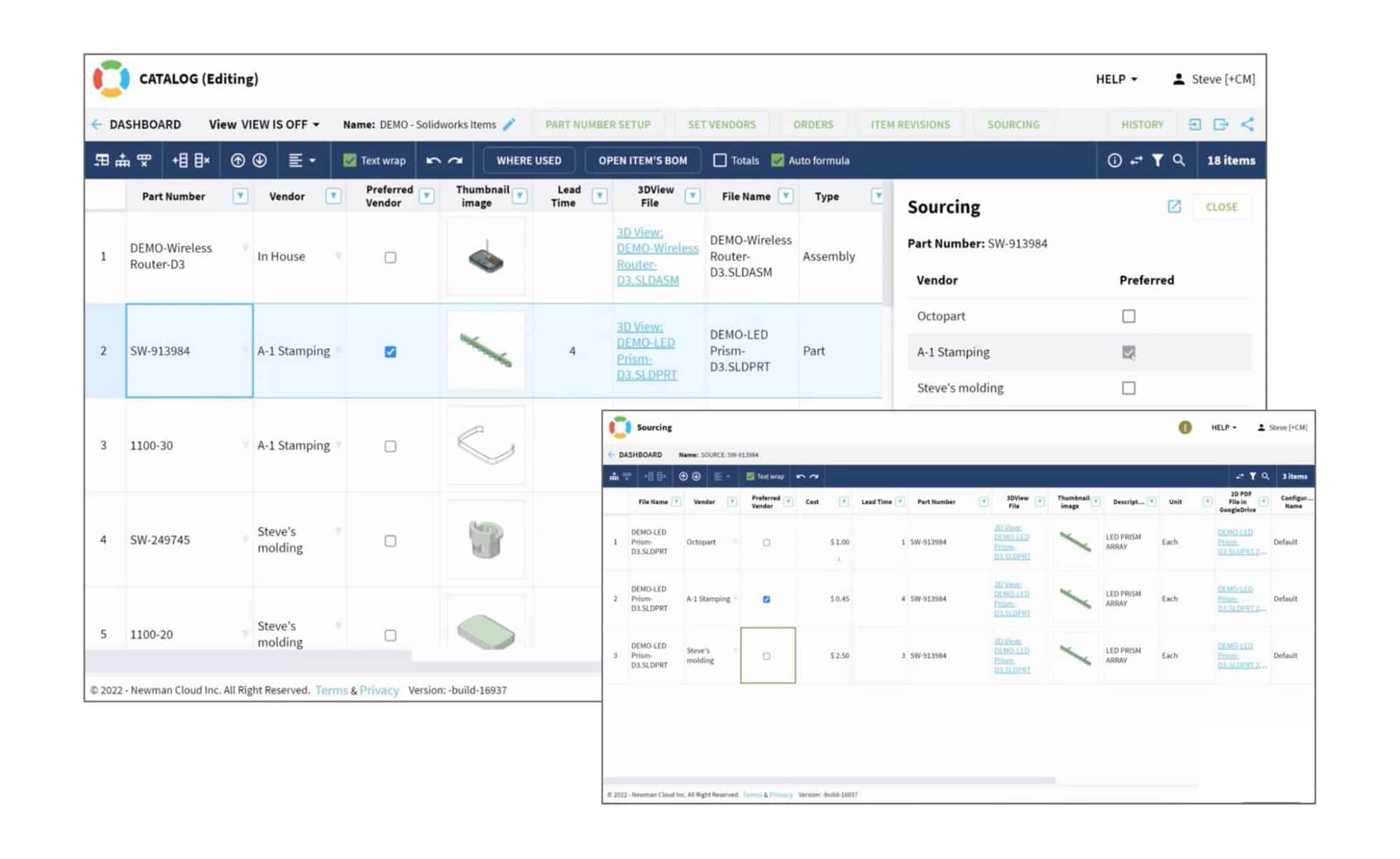

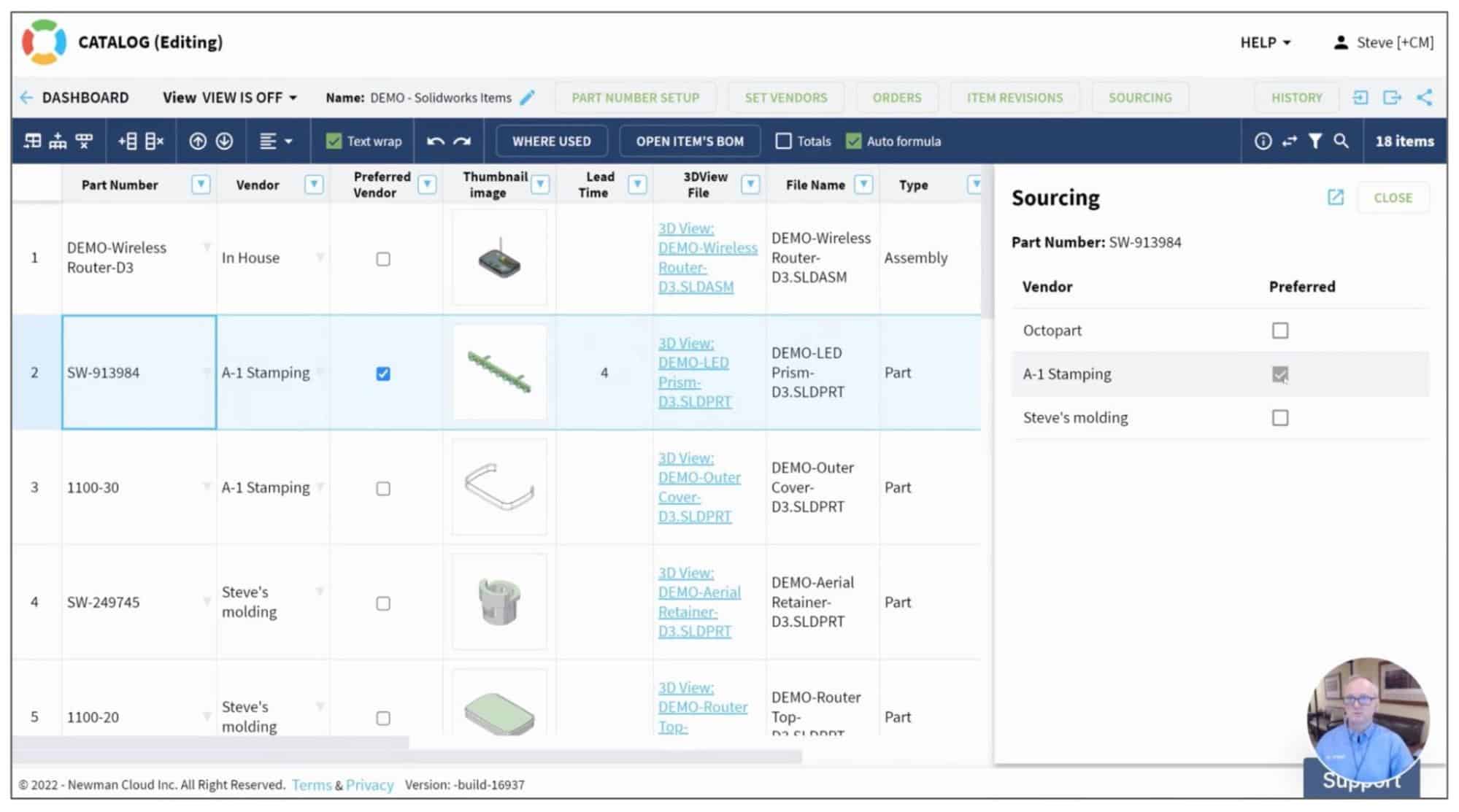

To select multiple sources for an item you can now use a new sourcing flyout that can give you an option to select the supplier of the component.

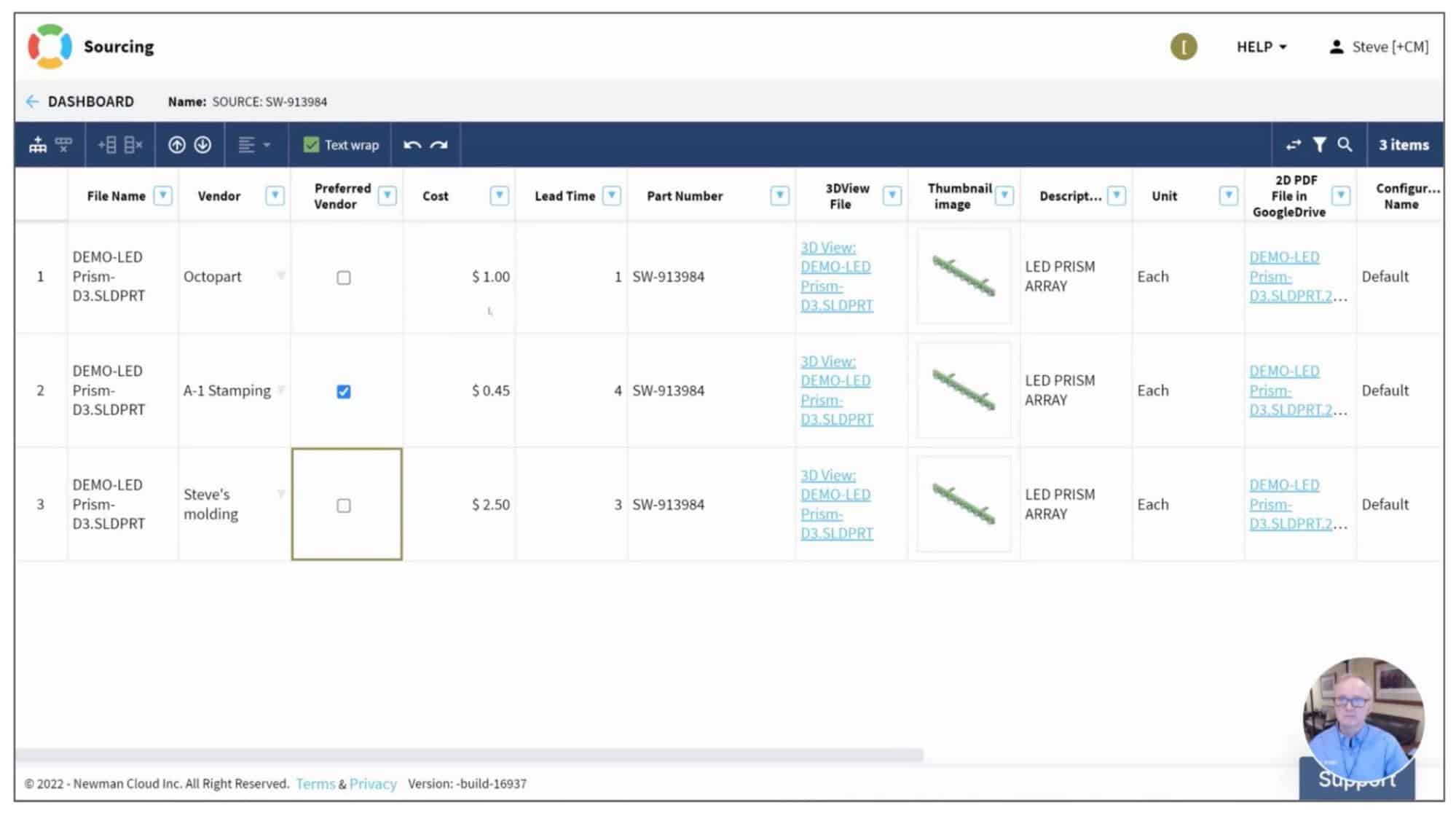

You can edit all sourcing options by navigating to the sourcing objects grid, which is similar to items in catalogs and has a fully flexible data model that allows you to define all attributes and characteristics of the supplier. This grid has real-time collaboration and simultaneous capabilities similar to all other OpenBOM objects using the same patented BOM collaboration methods.

A new multi-sourcing model allows you to define alternative suppliers for each item in the catalog and to define what is a preferred supplier. A preferred supplier item data will be used in all BOMs and will be used in the order that is created at the same time.

It is possible to switch between suppliers and create multiple orders to buy components from multiple suppliers at the same time.

Video Preview

In the following video, you can see a short preview of the functions. Stay tuned for more videos and detailed instructions on how to use the new multi-sourcing features.

Conclusion

A new OpenBOM multi-sourcing data model and user interface allows you to define multiple suppliers for the same item and use a preferred flag to choose a specific supplier at a time. Modeling items and suppliers (sources) in such a way provide an easy and flexible way to model item data for each different supplier (vendor) and use it in BOMs and catalogs for change management and orders.

The functions will be available soon in the next OpenBOM production update.

REGISTER FOR FREE to check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.