The manufacturing industry is rapidly evolving as businesses adopt digital transformation strategies to improve productivity, efficiency, and competitiveness. However, many manufacturing organizations are still reliant on legacy systems and processes that are slowing them down. In order to keep up with the latest trends and stay ahead of the competition, manufacturers need to embrace new technologies and innovative approaches to doing business. One way to do this is by utilizing online services that can help automate your operations and improve communication among team members and other companies. By using these services, manufacturers can streamline their workflows and optimize their processes, resulting in a more efficient and productive organization.

The Manufacturing Industry is Transforming

According to CIMdata research, about 70% of industrial companies in the CIMdata survey indicated that they are searching for new SaaS (services) and other digital technologies and applications that can replace existing legacy software to optimize their product development, supply chain, and operation efficiency. However, the process is not that easy and many manufacturing companies are looking for strategies and specific steps they can follow to transform their businesses into a new digital reality. In this article today, I will share our perspective on what is the role of online BOM services in the improvement of product development and manufacturing processes.

Digitalization and Digital Transformation

The process of using digital information to make your regular stuff work simpler and more efficient is digitization efforts. It is about keeping your business faster and better. It is about the accessibility of the information – to make it instantly accessible and not trapped into local Excel files or dusty PDF drawing archives. Think about sharing CAD drawings with your manufacturing contractor to make an order. Before you were sending paper drawings using FedEx service to your contractor and order to manufacture 20 pieces of widgets. By transforming the data in the digital format, you can find data much easier, access it instantly, and share it with a corresponded Bill of Materials to perform the order. Everything is moving faster, but the process is fundamentally the same.

As digital technologies evolved, the manufacturing industry started generating ways for using business technologies and computing services in a new way (not only to run it faster). This is where digital transformation starts.

Digital transformation is fundamentally changing the way manufacturing businesses get things done and sometimes creates even a new form of business and business models. With digital transformation, companies can step back and revise what they do – from their internal processes to interacting with customers and business partners. The fundamental transformation change comes at the point when companies are involved in a new process or change the existing one. For example, a manufacturing company can decide to make their online product information available online for their customer including all personalization of product (think of serial BOM) and use it for more efficient maintenance order management. Another example can be a cost reduction. A company can decide to run BOM cost analysis on all products they sell with all variations and, as a result, find a more optimal set of contractors and suppliers.

Both examples demonstrate how businesses can change the model and run a different process, which can get them unprecedented improvements. In my first example, it would be the ability to communicate online with the customers and ensure that maintenance orders are more precise, based on the specific product information and, as a result, to save expenses on ordering wrong parts, saving maintenance time, and improve customer experience. The second example demonstrates how you can use modern information access levels combined with online data analytics to calculate the cost, compare variants and recommend the best sourcing and contract manufacturing option.

Online (Web) Services

These days companies demand full-web service and offer a solution to enable communication between applications over the web. The services provide a standard way to communicate and exchange information. Companies are using web services because they can provide a platform-independent way to communicate. Web services are available as a “service provider” mode developing applications (think web services like AWS ML service and Database as a Service). Those are examples of web services, which can be available over the internet (web). Clients can consume these services for different purposes such as managing data or developing their own applications and processes.

BOM Services For Manufacturing Industry

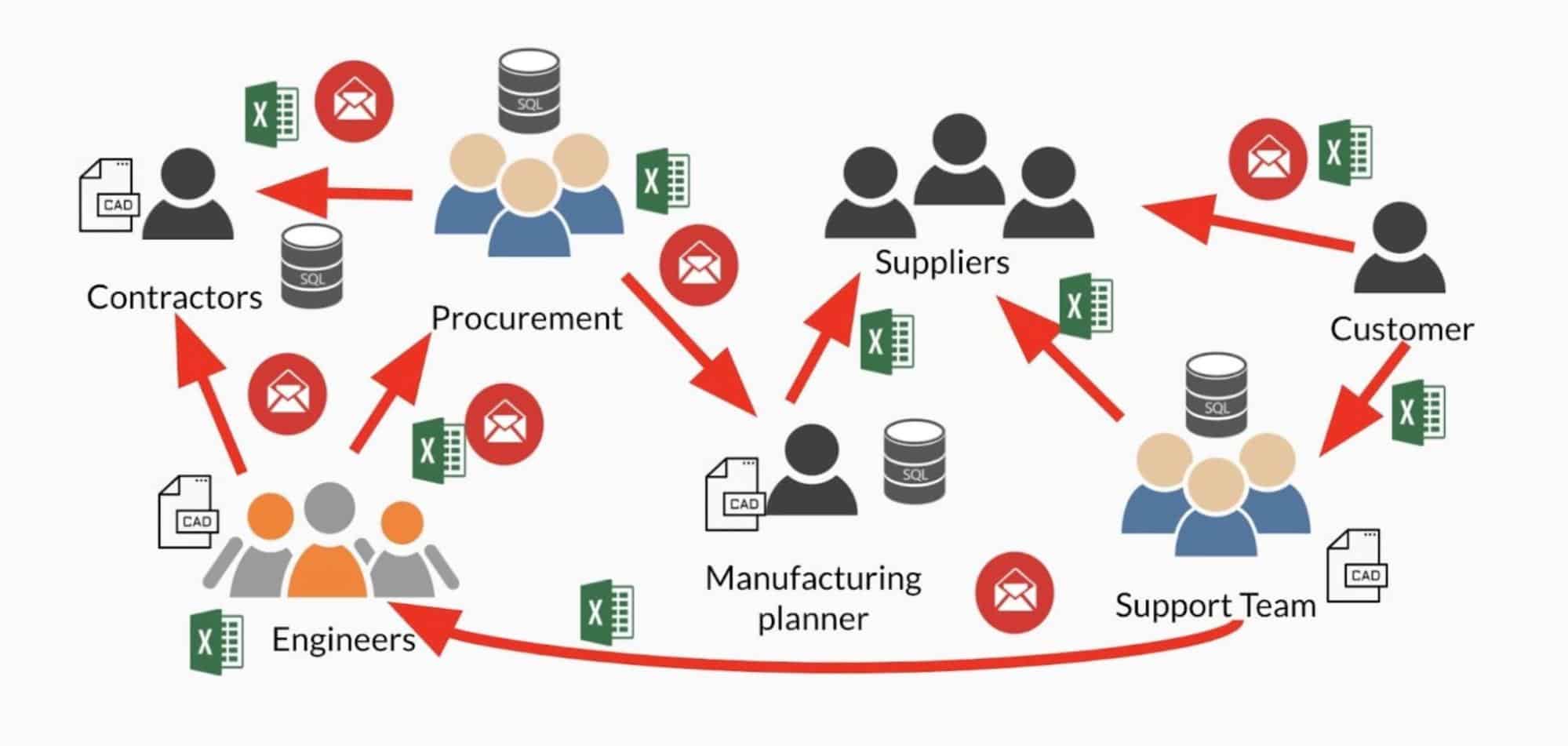

Manufacturing companies are facing substantial difficulties in running their businesses when it comes to the organization of data and processes. Most companies are using very mature point solutions for design, simulation, finance, and procurement. However, when it comes to connecting these pieces together, companies are not good and I’m continuously facing examples of digital chaos in the companies that can look something like the following picture.

The biggest problem in this chaotic communication is to have a persistent place where companies can manage product data information that can be easily integrated and shared among multiple product development, contractors, and suppliers organizations. The transformation is huge. In the past, companies were looking at how to get information under control to lock it in the company and to ensure the information is correct.

The new manufacturing world brings the next level of complexity – to have accurate information not only for the company itself but also to use this information to optimize their processes internally and externally. New business processes can involve a new generation of BOM services to perform optimization of these processes using new forms of digital assets and data.

Here are some examples of BOM web services:

- Item Catalog

- Bill of Materials

- BOM share

- Costing calculation

- (others)

These examples show you how much data assets and business functions can be available online to perform analysis, orders, and other processes using this data.

Conclusion

New manufacturing business models are the result of digital transformation in product development, procurement, supply chain, and production process. However, the improvement can not be done without making such data assets as “Bill of Materials” and related information online for business processes, analytics, and decision-making capabilities. At the first step, the manufacturing industry will establish BOM services to perform simple data representation and also speed up current processes (eg. revision control). However, within time, new BOM web services will be able to help manufacturing companies optimize the purchasing processes, optimize their work and decision making process with suppliers and contractors, and many others…

REGISTER TO OPENBOM for free and start a 14-days trial of all features and functions.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.