Back in 2020, we announced a partnership program at OpenBOM for consulting and online services.

Every day since COVID19 has disrupted our lives, work is moving in a new direction. Online and remote work is becoming more of the norm these days which has led to an uprise of SaaS use in order to optimize business processes without the need to leave home offices.

Usage of legacy data management systems for all engineers and manufacturing companies is one of the biggest showstoppers in their ability to work smoothly in remote locations. By introducing OpenBOM SaaS applications we found that there is a strong need to provide online services by connecting complex systems and making custom integrations.

Therefore we decided to start the OpenBOM partnership program and involve partners in our work with customers. Check this list of our partners and certified consultants here.

Razorleaf and Custom Integration

Today, I want to introduce a story of custom integration that was done by OpenBOM partner – Razorleaf.

Razorleaf was founded in 2000 with a goal to provide deep technical expertise that helps design engineering teams develop better products faster, cheaper, and more efficiently. We have been a driving force in the evolution of CAD as it has become a set of broader applications called Product Lifecycle Management (PLM). With thousands of projects under our belt, we’ve learned the pitfalls and nuances of the various platforms. We take exceptional pride in how we help bridge the gap between tough business problems and the technologies that support them.

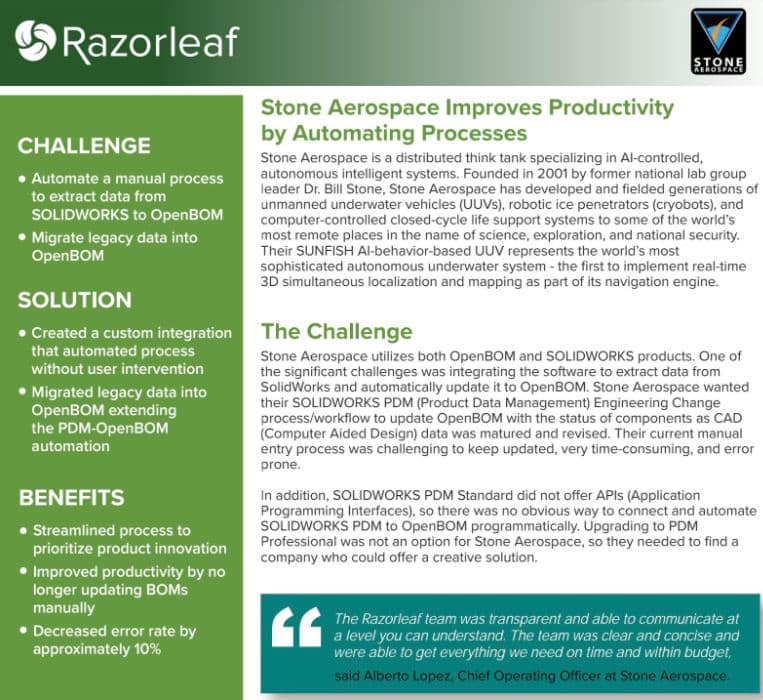

For the last several months, Razorleaf has been working directly with OpenBOM customer – Stone Aerospace to develop a custom automatic process between OpenBOM applications and SOLIDWORKS PDM Standard. The PDM standard is a system developed years ago and the customer has the demand to automate processes and connect dots to streamline the information flow.

Stone Aerospace is a distributed think tank specializing in AI-controlled, unmanned underwater vehicles (UUVs), robotic ice penetrators (cryobots), and computer-controlled closed-cycle life support systems to some of the world’s most remote places in the name of science, exploration, and national security. Their SUNFISH AI-behavior-based UUV represents the world’s most sophisticated autonomous underwater system – the first to implement real-time 3D simultaneous localization and mapping as part of its navigation engine.

Read more about what Razorleaf developed for Stone Aerospace.

Conclusion

At OpenBOM we focus on how to provide the most innovative solution for our customers. Our goal is to not limit ourselves but instead make it a priority to collaborate with our customers to develop solutions to unique problems.

The example of Razorleaf is a great demonstration of how modern SaaS services (eg. OpenBOM) can extend existing legacy solutions (eg. SOLIDWORKS PDM Standard) to connect dots and bring information online and streamline the process.

Congratulations Razorleaf team on these accomplishments!

Check out what OpenBOM can do for your business by registering for FREE and starting a 14-days trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.