Part Number is a topic that usually generates a lot of discussions in engineering and product development teams. Historically, manufacturing companies were inventing a complex system of part numbers to reflect on a variety of topics – component type, version, the specific number, revision, and many others. Modern software changed the paradigm of work by bringing new cloud-based software that can automate tedious data management tasks while keeping things simple.

At OpenBOM we create a system that helps to automate the part number creations process. Each OpenBOM catalog has a pattern on how to generate part numbers and keep them unique. OpenBOM company features allow keeping track and uniqueness of part numbers for an entire company.

For the last few months, we’ve been focusing on how to simplify the process of part numbering in OpenBOM CAD integrations by allowing users to get the next available part number and assign it to CAD files or components.

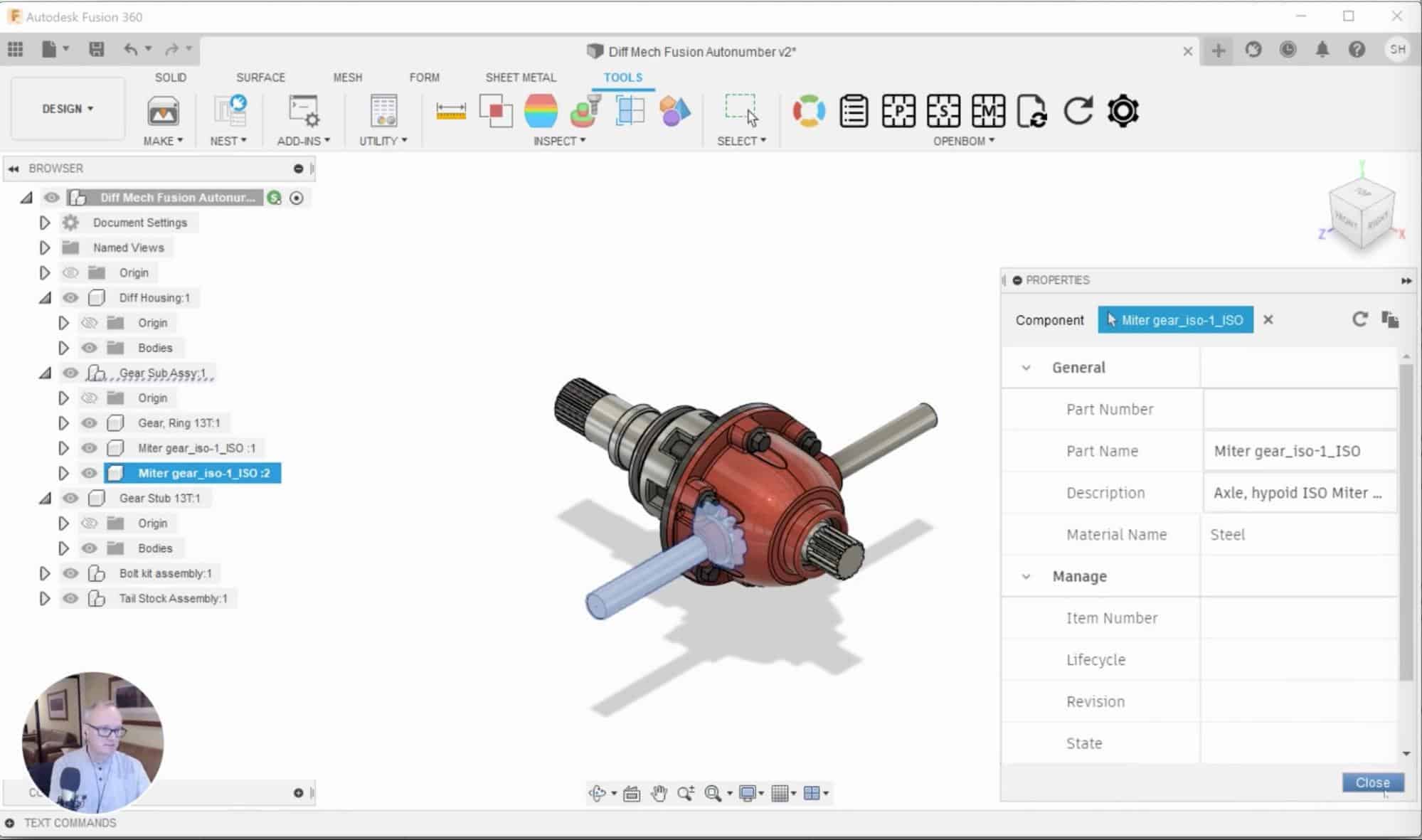

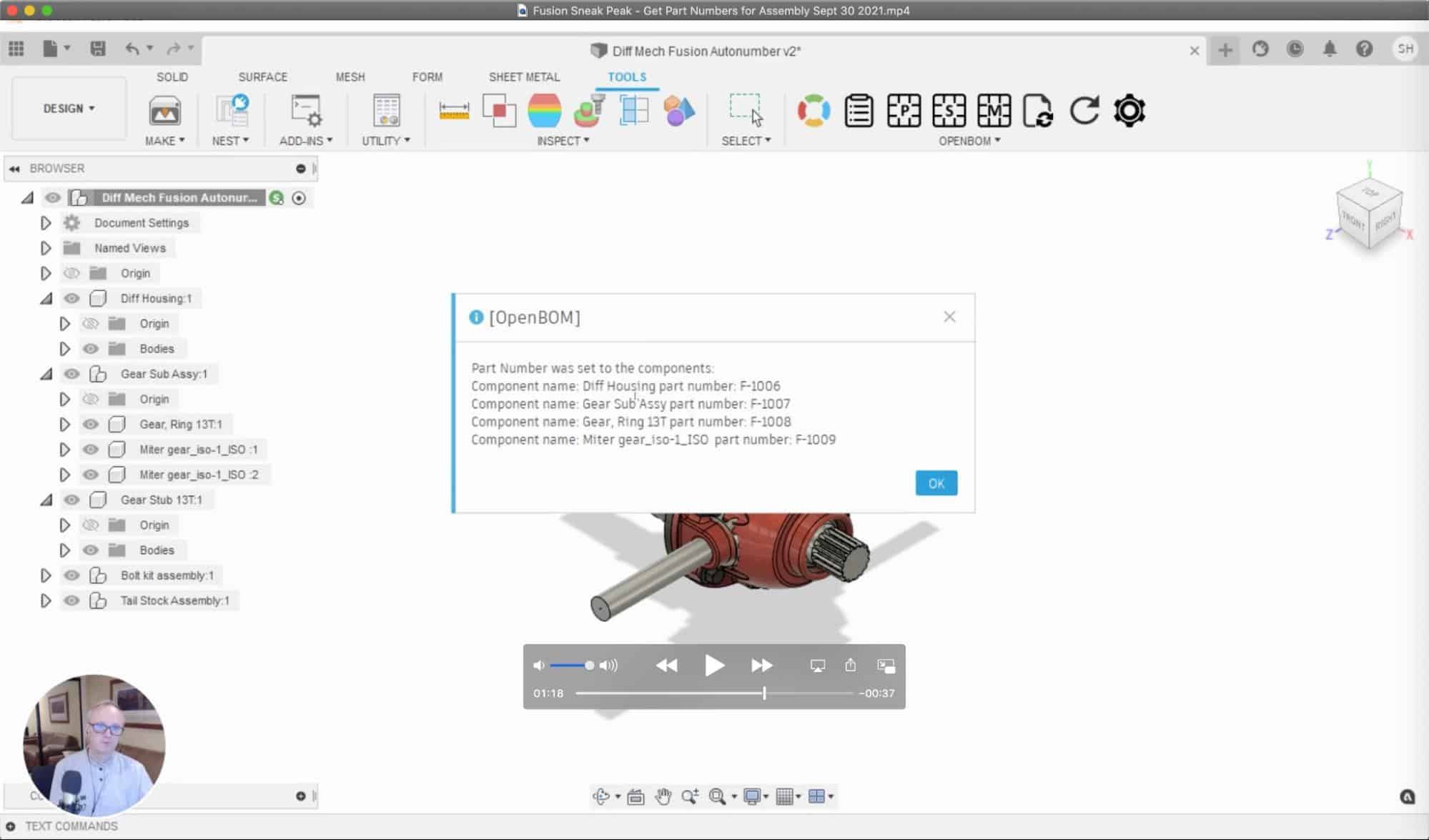

In this coming release, we take it to the next level and bring automation to this process by allowing users to assign part numbers automatically to an entire assembly. A few days ago, I published a Solidworks example here. Today, I want to show how similar functionality will become available in Autodesk Fusion360.

A very specific characteristic of Autodesk Fusion 360 is total flexibility on names. Fusion 360 keeps the data in the cloud and doesn’t use file names, so you can create components with any name which usually leads to high difficulties in data identification. Exporting these names doesn’t give much help, manual assignments of names are also hard.

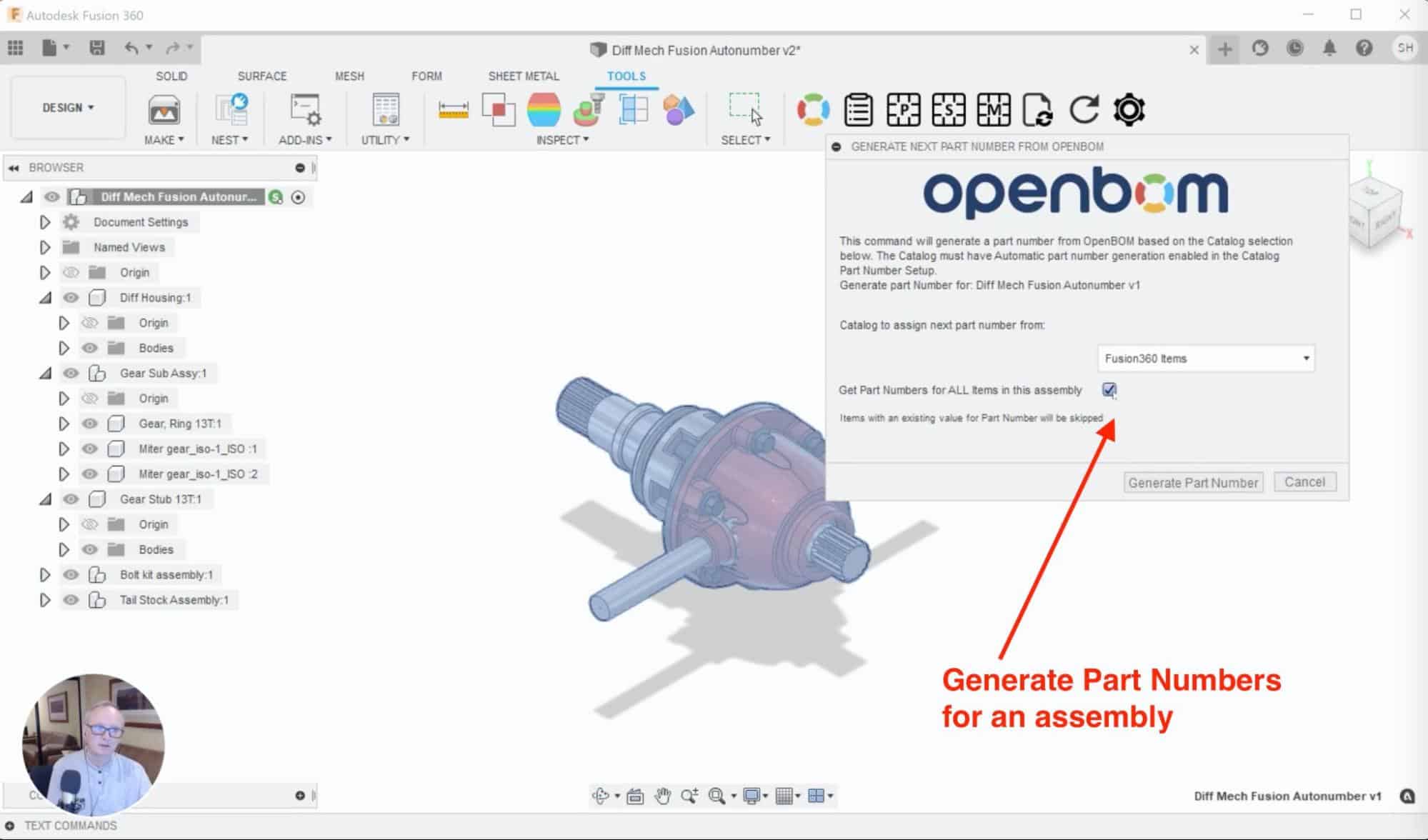

This is how you see it with empty Part Numbers.

OpenBOM’s new feature allows generating Part Numbers based on the catalog settings automatically.

Once data is generated, you can save the BOM and get all Fusion360 data aligned with newly assigned part numbers.

Check out the video below for a preview of the feature to see how it works.

Conclusion

Managing Part Number is a topic that raises tons of questions and debates in engineering organizations. It is also a tedious task in a CAD environment, which is flexible and doesn’t force users to assign them upfront. Autodesk Fusion 360 is a great example. You can literally name all components by any name. But once the design is done, you need to create a Bill of Materials and this task takes tons of time. OpenBOM gives you full end-to-end automation that literally takes 2 clicks – to generate part numbers and save the BOM to OpenBOM.

Check out what OpenBOM can do for you. REGISTER FOR FREE and start your 14-day free trial to test all of OpenBOM’s functions.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.