At OpenBOM, we’ve always been focused on how to provide the most flexible solution for data management understanding that no one manufacturing company in the world is the same and to be able to adapt and support design and manufacturing processes is important without coming with a “one big bang” solution.

The Importance of Part Numbers

There are very few things that touch engineering minds working in product development and manufacturing more than Part Numbers. Speaking with thousands of customers – engineers, contractors, suppliers, procurement people, and many others, we always found how the topic of Part Number comes up as a core issue to decide and agree about. It comes with no surprise because everything else is relying on how processes will be working – BOM will be generated, procurement will be done, new revisions will be created, and many others. The question of using meaningful part numbers vs just numbers is just one example.

Flexibility and efficiency are the key elements of OpenBOM architecture and solution. I’m very excited about the upcoming enhancements of OpenBOM CAD Add-ins to support the automatic generation of part numbers as part of the process of saving data from CAD System to OpenBOM. We found it to be a fundamental step in taking data under control and making it available downstream.

Automatic Part Number Generation

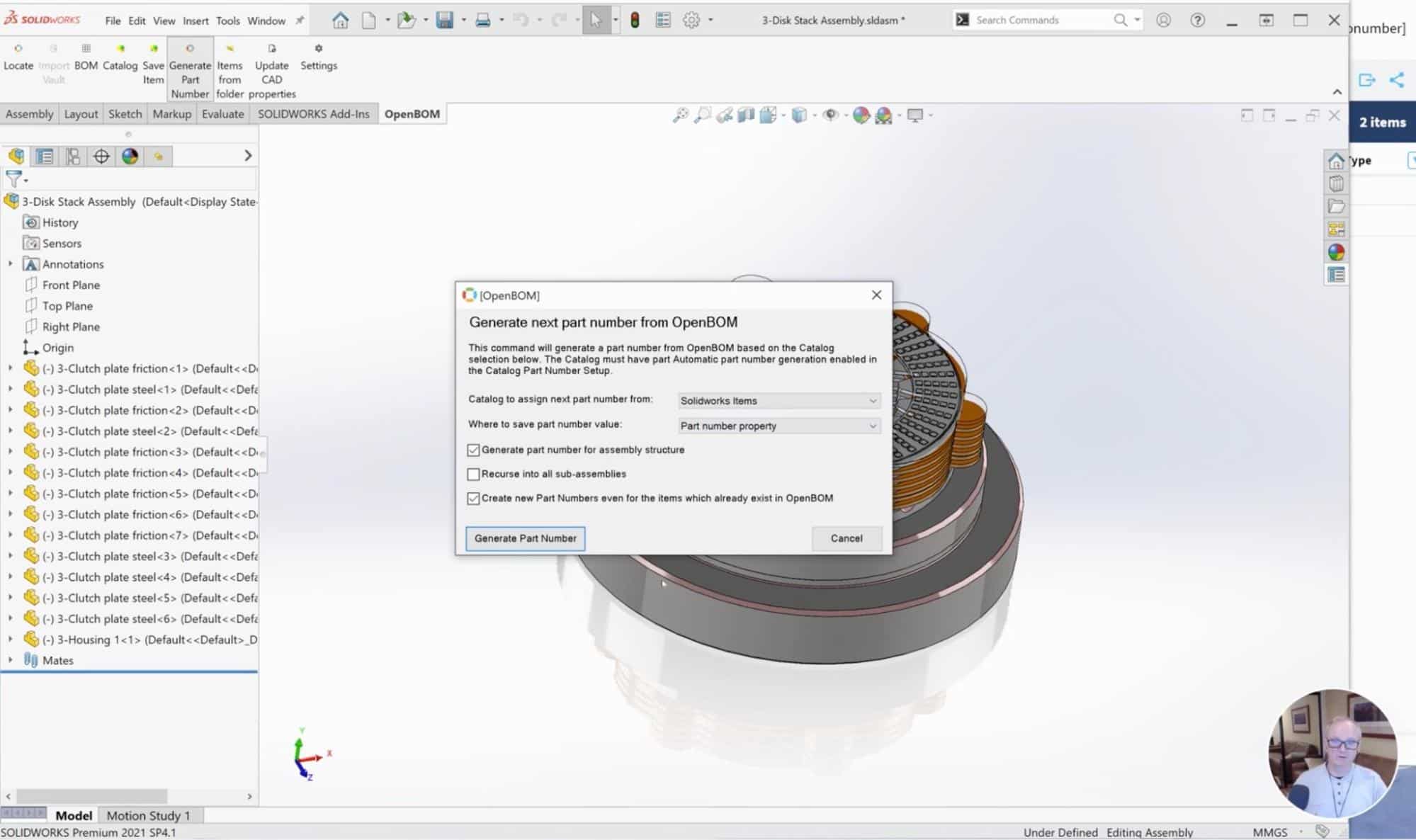

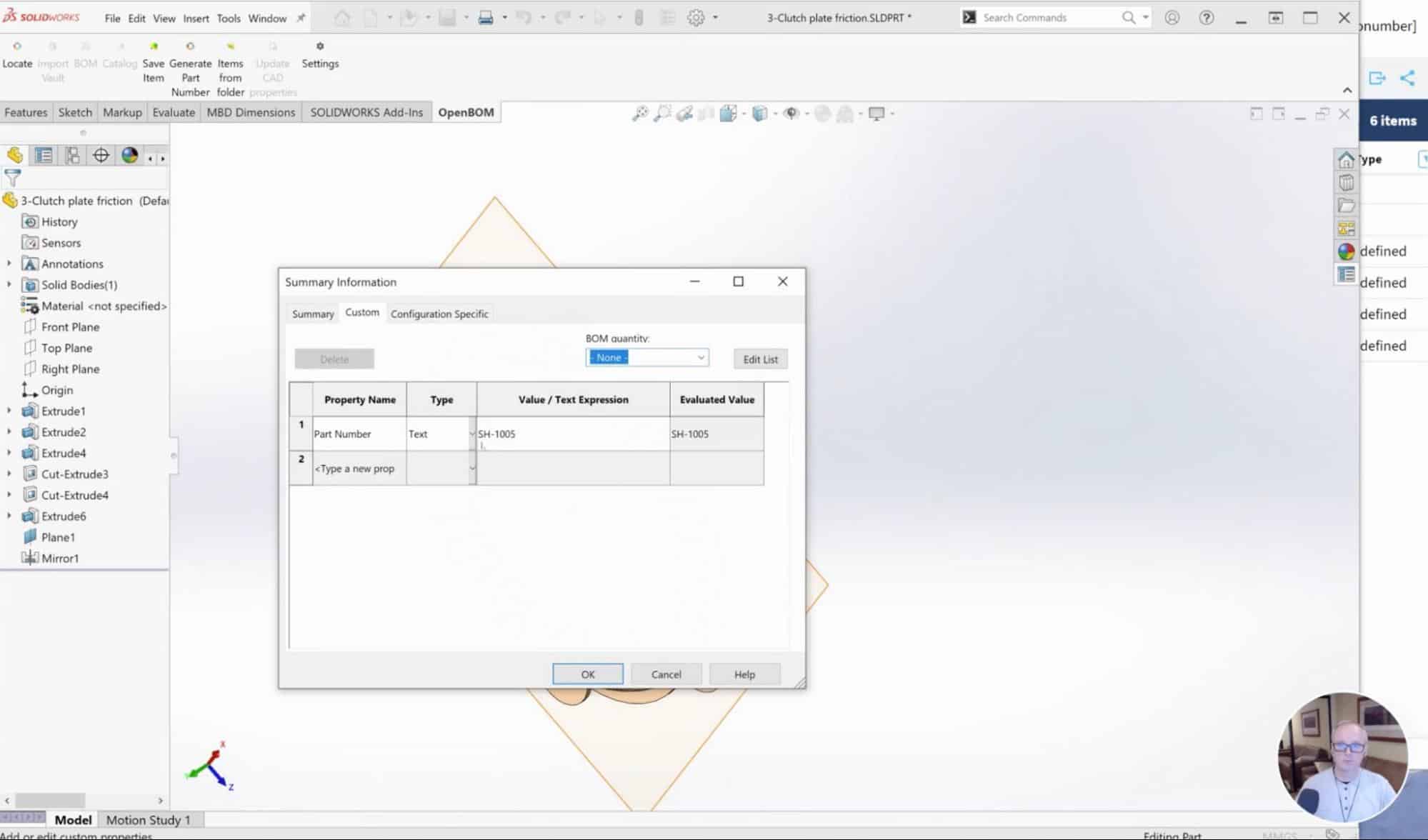

In this article, you can see an example of how the new feature is implemented in SOLIDWORKS Add-in. The existing Get Part Number dialog will have new options – to generate Part Numbers to all parts and sub-level assemblies. It will ignore it in the case that assembly or component is already saved in OpenBOM.

Once the Part Numbers are automatically generated, you will see them saved in all CAD files belonging to the assembly, parts, and sub-assemblies.

Watch the video below to get a better idea of how it will work once it is released.

Conclusion

Automation is very important in data management. After all, everyone needs the data, but nobody wants to manage it. So, by taking a step and automating the process and, at the same time, keeping it flexible, we can achieve the desired results – OpenBOM can take any CAD assembly and generate a complete product structure, while making an automatic reservation of part numbers and then saving the metadata, CAD files and derivatives (PDF, STEP, DXF) files to OpenBOM cloud. The data becomes available for downstream usage in an entire organization which makes everyone happy!

Check out what OpenBOM can do for you, REGISTER FOR FREE and start your 14-day trial today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.