For decades, PDM meant file vaults, check-in/check-out, and revision control. But today’s products span mechanical, electronic, and software domains, with supply chains demanding real-time collaboration and traceability—challenges legacy PDM can’t meet.

A new era is emerging: cloud-native, multi-disciplinary, and AI-ready. In this article, we explore how OpenBOM redefines PDM as a flexible digital framework, connecting design data, BOMs, and processes into an engineering digital thread.

In my article earlier last week, I covered 30 years of PDM history—what we learned, what has changed, and what remains the same.

Today, I want to share more details about the evolving OpenBOM PDM strategy and how it is going to evolve in the next 3-5 years.

PDM Is Evolving

Product Data Management (PDM) has been a central part of engineering software for more than 30 years. For decades, companies relied on PDM systems to keep CAD files organized, control versions, and prevent accidental overwrites. At its core, PDM solved a practical problem—“who saved last?”—by providing vaults and check-in/check-out workflows for engineering files.

But the world of product development has changed. Supply chains are global and distributed. Products themselves are far more complex, combining mechanical systems, electronics, software, and connected services. Manufacturing environments demand agility, compliance, and traceability across every step of the lifecycle.

In this new reality, traditional PDM approaches are no longer sufficient. Engineering teams are being asked to collaborate across disciplines, suppliers, and tools in ways that were unimaginable when legacy PDM systems were first designed. PDM is evolving, and the question is not whether change is needed, but how quickly organizations can adapt.

The Current Transformational Stage

The transformation of PDM is not happening in a single leap. Instead, the current landscape is best described as a coexistence of three generations of PDM architecture. Most companies today are navigating a mix of these approaches, sometimes even within the same organization.

1. Aging File Vaults and Databases (Legacy PDM/PLM)

The first generation of PDM was centered around file vaults. These systems—often built on relational databases and installed on-premise—focused on storing, indexing, and protecting CAD files. Systems like SmarTeam, Intralink, and early versions of Teamcenter or Windchill became staples in many enterprises.

While reliable, these solutions are now aging. They require heavy IT infrastructure, VPN connections, and specialized support. Integrations are limited, and expanding them to cover modern disciplines like ECAD, software, or cloud collaboration is either extremely costly or impossible.

2. Maturing Online/Cloud-Based Solutions

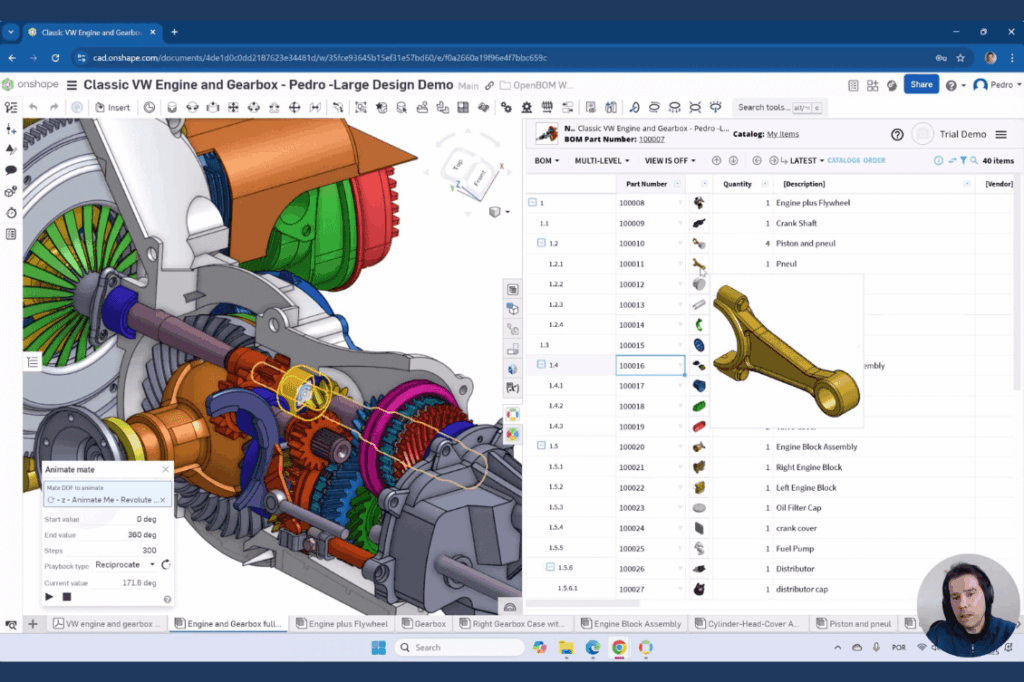

The second generation reflects the rise of cloud computing and SaaS. Tools like Autodesk Fusion, Onshape, and a new wave of PDM/PLM vendors redefined expectations by delivering collaboration through the browser.

These systems offer multi-tenant environments, real-time data access, and easier sharing beyond the firewall. They are less IT-intensive and scale better for distributed teams. However, while cloud PDM is maturing, many platforms remain siloed around specific CAD ecosystems, limiting their ability to connect multi-disciplinary product data.

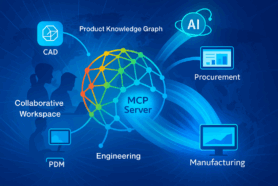

3. Emerging AI-Driven Capabilities

The third generation is only beginning to emerge. Powered by AI and machine learning, these systems move beyond storing and sharing data to actively understanding and reasoning over it. Intelligent agents can answer questions like:

- “Where is this component used across all designs?”

- “What has changed between these two revisions?”

- “Which design alternatives will reduce cost given supplier constraints?”

AI also enables automated classification, anomaly detection, and decision support. While still early, the direction is clear: the future of PDM is intelligent, proactive, and embedded in the workflows of engineers and manufacturers.

How OpenBOM PDM Solves the Problem

At OpenBOM, we believe that modern PDM must move beyond the limitations of vaults and CAD-centric silos.

Our strategy is built on three key principles:

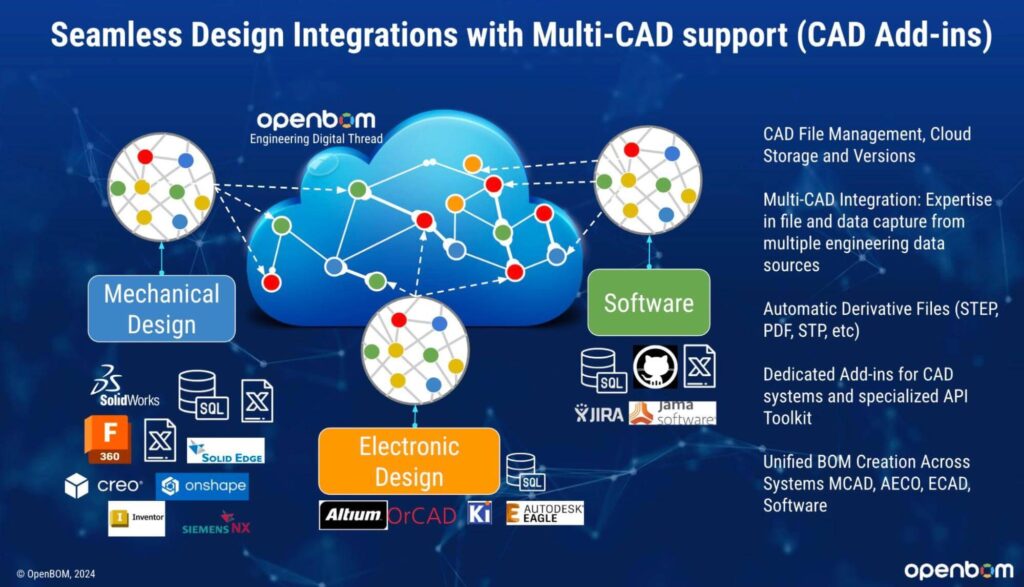

- Flexible Data Management – Instead of rigid schemas tied to a single CAD tool, OpenBOM provides a graph-based, multi-tenant data model capable of representing mechanical, electrical, electronic, and software elements together.

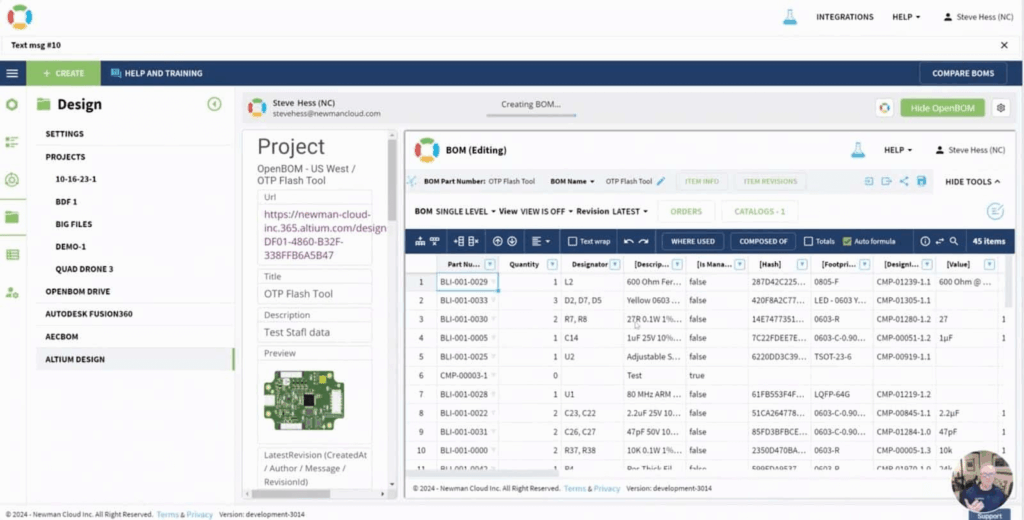

- Seamless Integrations – OpenBOM connects directly to leading CAD systems (SOLIDWORKS, Autodesk Fusion, Altium, Onshape, and others), as well as downstream systems like ERP and procurement. This ensures that engineering data flows smoothly across the lifecycle.

- Engineering Digital Thread – By connecting design, BOMs, suppliers, and processes in one environment, OpenBOM enables an engineering digital thread—a unified system of record that keeps data accurate, traceable, and accessible to everyone who needs it.

The result is a PDM that doesn’t just manage files, but actively enables collaboration, decision-making, and product innovation.

Three Elements of OpenBOM PDM Integrations

Modern PDM cannot be one-dimensional. OpenBOM PDM provides a holistic integration strategy across multiple layers of engineering workflows.

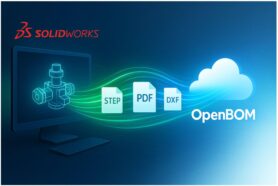

1. Design Project Items: Managing File Objects and Lifecycles

At the foundation, engineers still need to manage design files. OpenBOM introduces Design Project Items, a flexible object type for capturing files, revisions, and associated metadata.

- Lifecycle Management – From “In Work” to “Released” to “Obsolete,” OpenBOM supports configurable lifecycle states.

- Collaborative Locks & Check-in/Out – Engineers can safely work in parallel, with mechanisms to prevent overwrites and ensure controlled releases.

- File Synchronization – CAD files, PDFs, STEP, and other derivatives are synchronized automatically, ensuring that downstream teams always access the right versions.

This approach modernizes the classic vault concept but embeds it within a flexible, cloud-native framework.

2. Cloud Connected Systems

The next layer of integration comes from direct connections to cloud-based design tools. OpenBOM provides deep integrations with systems like Autodesk Fusion and Altium Designer, enabling real-time continuity of data.

For example:

- A PCB layout created in Altium can push its BOM directly into OpenBOM, where it is connected with mechanical assemblies from Fusion.

- Changes made in the CAD tool are reflected instantly in the BOM, ensuring procurement and manufacturing teams always see the latest design intent.

This eliminates the manual exports and error-prone spreadsheet merges that plague traditional workflows.

3. Cloud Integrated PDM Interfaces

Finally, OpenBOM takes PDM beyond simple file synchronization by embedding cloud CAD functions directly into its environment. Engineers can interact with design data, visualize structures, and run comparisons without leaving OpenBOM.

This creates a seamless user experience: PDM is no longer a separate “vault application” but part of the daily design and collaboration flow. The result is higher adoption, fewer errors, and faster product development cycles.

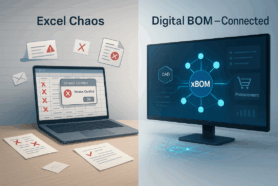

Digital BOM as a Framework

At the heart of OpenBOM PDM is the Digital BOM (Bill of Materials)—a framework that unifies data across disciplines into a coherent, connected structure.

Unlike static spreadsheets, the Digital BOM is dynamic and graph-based. It can represent multiple product perspectives:

- MCAD assemblies from SOLIDWORKS or Fusion.

- ECAD designs from Altium or Eagle.

- Software components and configurations.

- Suppliers, cost, and lifecycle information.

By weaving these branches together, OpenBOM provides:

- Traceability – Every part, file, and revision can be traced back to its source.

- Collaboration – Mechanical, electrical, and software engineers work in the same digital context.

- Decision Support – Procurement, compliance, and manufacturing teams can evaluate designs earlier and with more confidence.

In this way, the Digital BOM serves as the data backbone of modern PDM, extending well beyond the vault to become a true system of product knowledge.

Conclusion: From Vaults to Frameworks to Intelligence

PDM has traveled a long road since its origins as a CAD file vault. For decades, it was about preventing overwrites and managing revisions. But the demands of today’s engineering and manufacturing environment are forcing a new paradigm.

- Yesterday’s PDM: Aging file vaults and legacy databases.

- Today’s PDM: Cloud-native, collaborative, and multi-disciplinary data backbones.

- Tomorrow’s PDM: Intelligent, AI-enabled systems that reason, automate, and connect the entire digital thread.

OpenBOM PDM is designed with this trajectory in mind. By combining flexible data management, seamless integrations, and the Digital BOM framework, OpenBOM empowers companies to leave behind the limitations of legacy vaults and embrace a future where product data is not just stored, but actively leveraged for innovation.

The future of PDM is about data intelligence, connectivity, and flexibility. And OpenBOM is building that future—today.

Want to check how OpenBOM can help?

REGISTER FOR FREE and try it for 14 days/

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.