In the complex landscape of product development, managing costs efficiently is paramount for success. Yet, traditional methods such as spreadsheets often fall short, lacking consistency, centralized data sources, and streamlined calculation processes.

This is where OpenBOM steps in, revolutionizing cost management with its comprehensive platform. Let’s explore how OpenBOM reshapes the cost management paradigm.

The Spreadsheet Complexity

Spreadsheets have long been a ubiquitous tool for managing various aspects of business operations. However, when it comes to cost management in product development, they reveal their limitations. Spreadsheets lack consistency, fail to provide a centralized source of cost data, and offer limited capabilities for rolling up values using formulas.

OpenBOM: Centralized Item Management

OpenBOM offers a solution that transcends the constraints of spreadsheets. It provides an intuitive platform for centralized item management, enabling users to add diverse attributes, manage files, revisions, supplier sources, and seamlessly share cost data with stakeholders.

The Power of Rollup Formulas

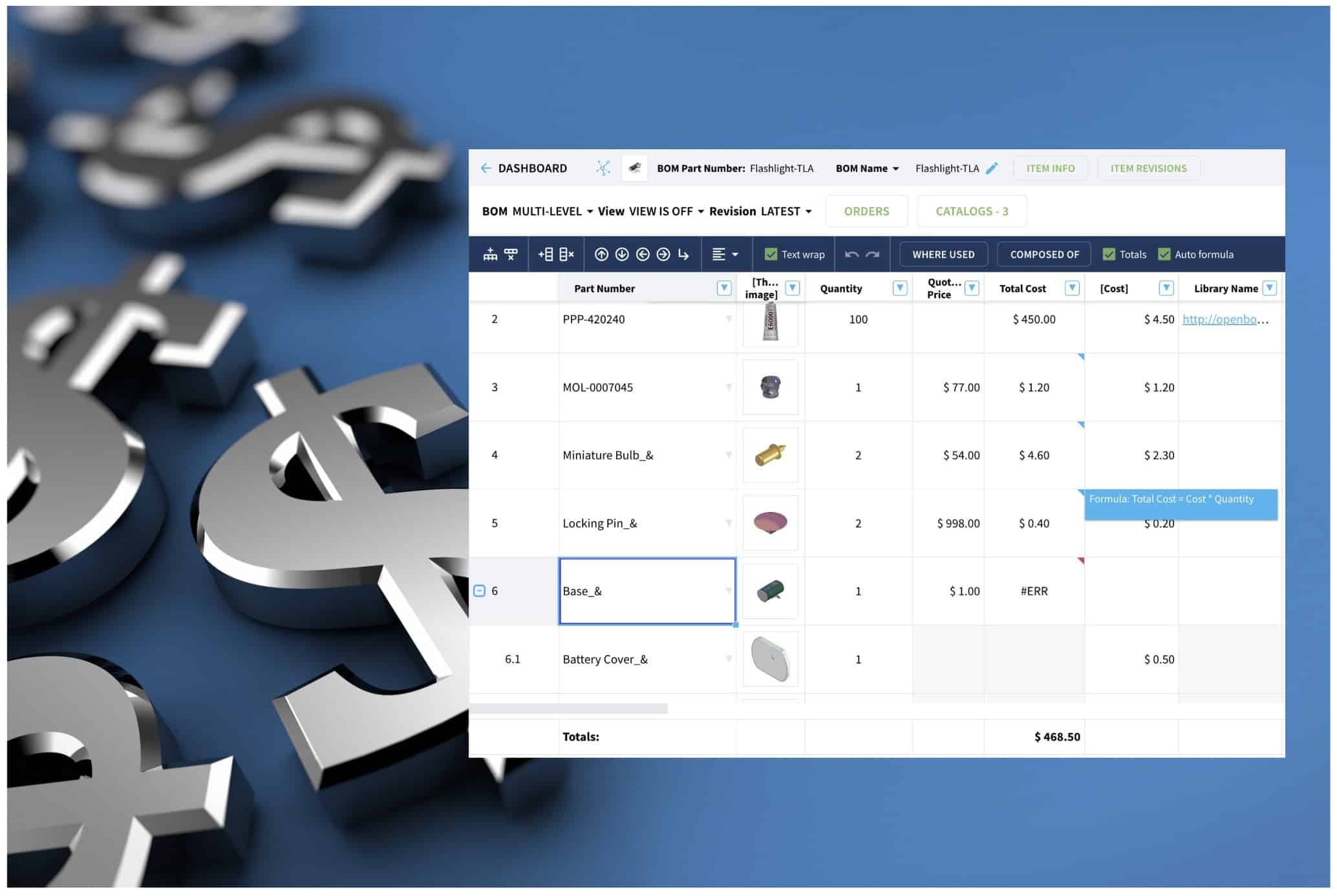

A very powerful feature of OpenBOM is its rollup formula mechanism, which empowers users to consolidate all cost information and perform complex calculations effortlessly. Unlike Excel, OpenBOM’s rollup capabilities streamline the process, enhancing efficiency and accuracy in cost management.

Integration and Data Accessibility

OpenBOM further distinguishes itself through seamless integration with CAD systems such as Solidworks. Moreover, its user-friendly interface facilitates easy import of existing Excel and Google Sheets, ensuring a smooth transition and connectivity with pre-existing data sources.

Live Demo: Witness the Process of How To Organize Cost Data

Experience the transformative capabilities of OpenBOM firsthand by joining our live demo. Witness how OpenBOM streamlines cost management processes, fosters collaboration, and drives innovation in product development.

Conclusion: Embrace Digital Transformation

In the digital age, relying on disparate spreadsheets for cost management is no longer viable. OpenBOM offers a compelling alternative, enabling organizations to centralize data, streamline processes, and gain early visibility into costs. By embracing OpenBOM, businesses can support agile new product development initiatives, driving growth and innovation.

Take Action: Explore OpenBOM

Don’t let outdated methods impede your progress. Register for OpenBOM today and embark on a journey towards streamlined cost management and enhanced productivity. Experience the future of product development with OpenBOM.

REGISTER FOR FREE and learn more about how OpenBOM can help.

Best regards,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.