Efficient data management and integration are crucial for modern manufacturing companies. Engineering and manufacturing processes need to be connected and multiple applications must interplay together to support fast engineering to manufacturing turnaround.

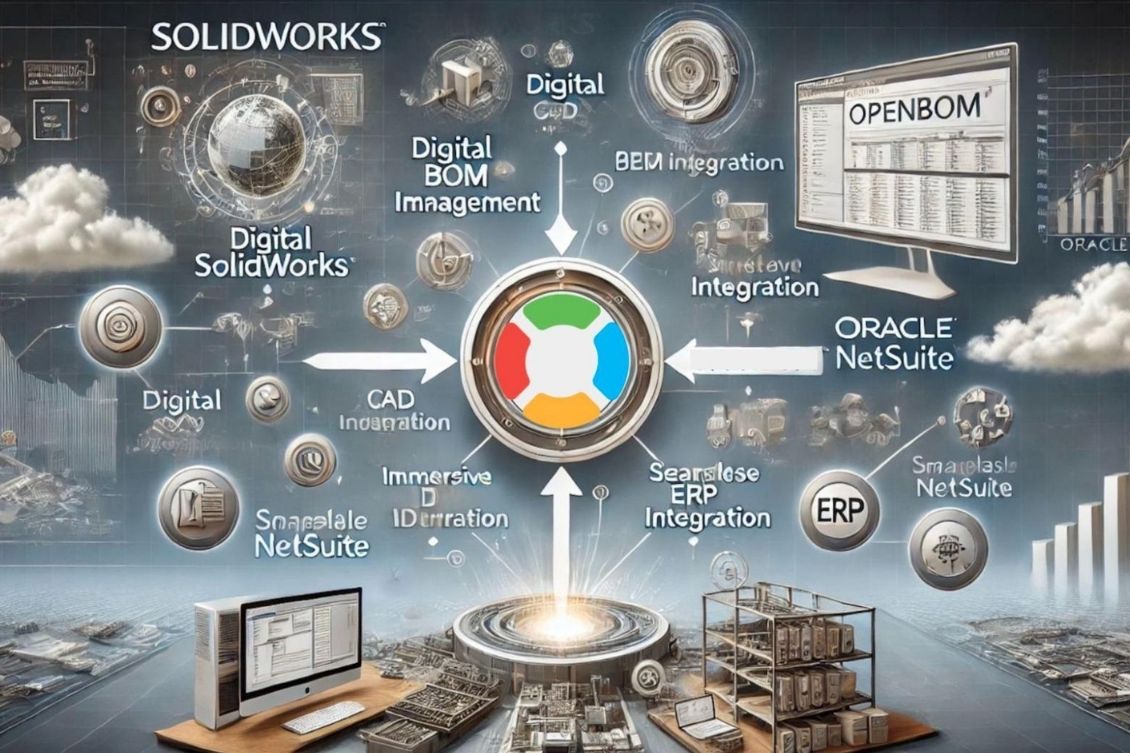

OpenBOM’s flexible model is designed to capture and organize product information across design, engineering, manufacturing, and finance. At the heart of OpenBOM is a three-point strategy that drives its success: (1) Digital BOM Management, (2) Immersive CAD Integration, and (2) Seamless Inventory and ERP Integration. Each of these pillars plays a critical role in enabling companies to manage engineering data effectively and connect it seamlessly with ERP systems. This strategy empowers companies to manage their engineering data effectively and seamlessly connect it with their ERP systems, creating an integrated and connected lifecycle process.

In this article I’ll share more Digital BOM Management, Immersive CAD Integration, and Seamless ERP Integration.

Capturing Product Data with OpenBOM

OpenBOM’s unique data model empowers users to capture product information at every stage of development. From detailed design data generated in SolidWorks to engineering bills of materials (EBOM) and manufacturing bills of materials (MBOM), OpenBOM acts as a central hub for organizing and sharing information. By bridging the gap between engineering and business systems, OpenBOM ensures that critical data flows freely and accurately throughout the organization.

Integration for a Connected Lifecycle Process

OpenBOM’s integrations are key to enabling a connected lifecycle process. By linking SolidWorks and Oracle NetSuite, OpenBOM allows teams to manage their workflows more effectively and reduce delays caused by siloed systems. The integration supports real-time data synchronization, streamlining the process from engineering design to manufacturing and finance.

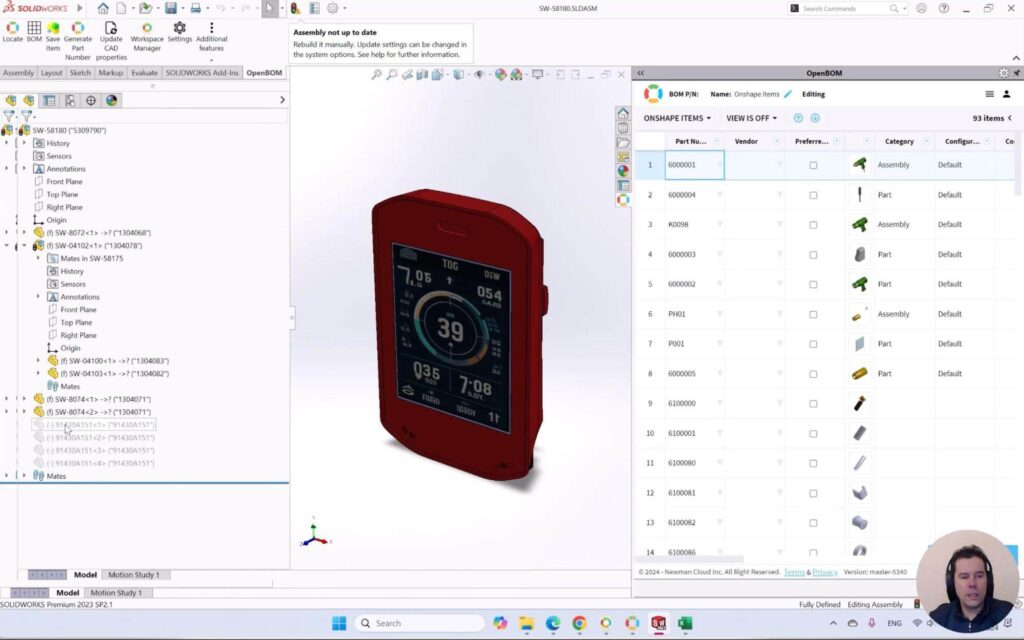

The Process: From Design to ERP

The process we demonstrate today highlights the power of OpenBOM’s integrations and includes the following steps. Starting in SolidWorks, OpenBOM captures design data and automatically generates an engineering bill of materials (EBOM), ensuring that all design-related data is documented and structured for downstream processes.

OpenBOM captures EBOM directly from Solidworks.

With tools for managing engineering changes, updates are reflected accurately across the lifecycle. OpenBOM’s embedded interface in Oracle NetSuite enables seamless access to engineering data, eliminating the need to switch between systems and improving collaboration.

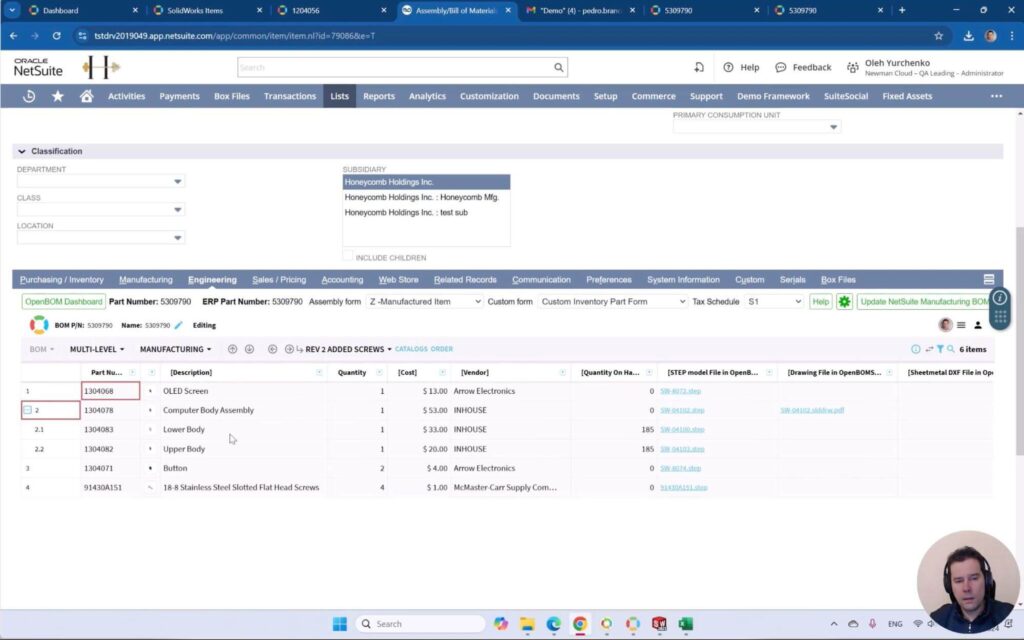

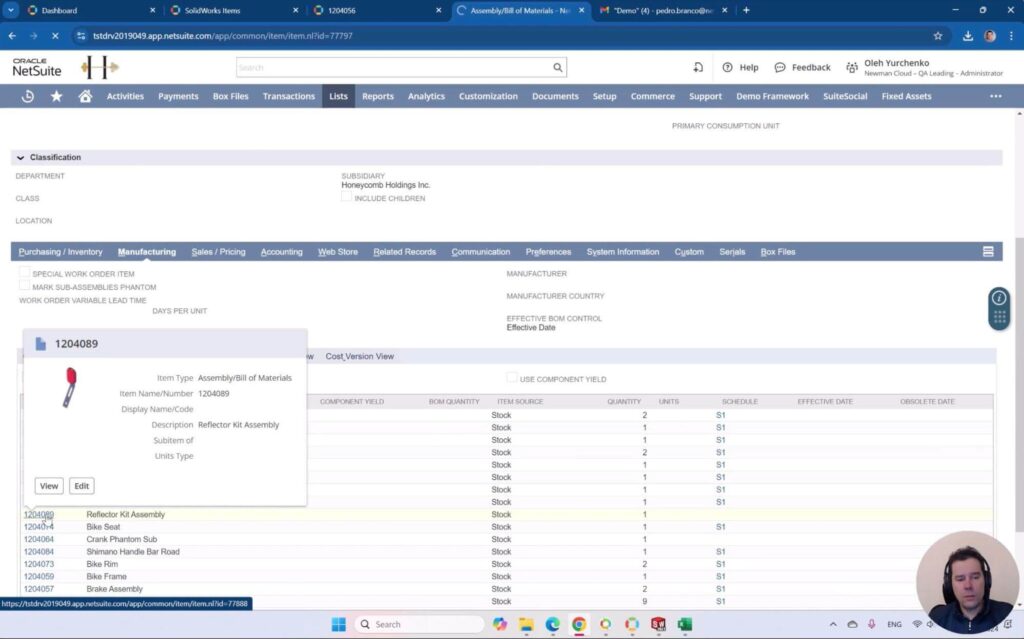

The EBOM created in OpenBOM is seamlessly integrated and available via the Engineering Tab in Oracle NetSuite allowing real-time collaboration between engineering departments working with EBOM and Manufacturing planning done in Oracle NetSuite.

Finally, OpenBOM synchronizes the EBOM with the MBOM in NetSuite, ensuring that manufacturing and supply chain teams have the latest, most accurate data.

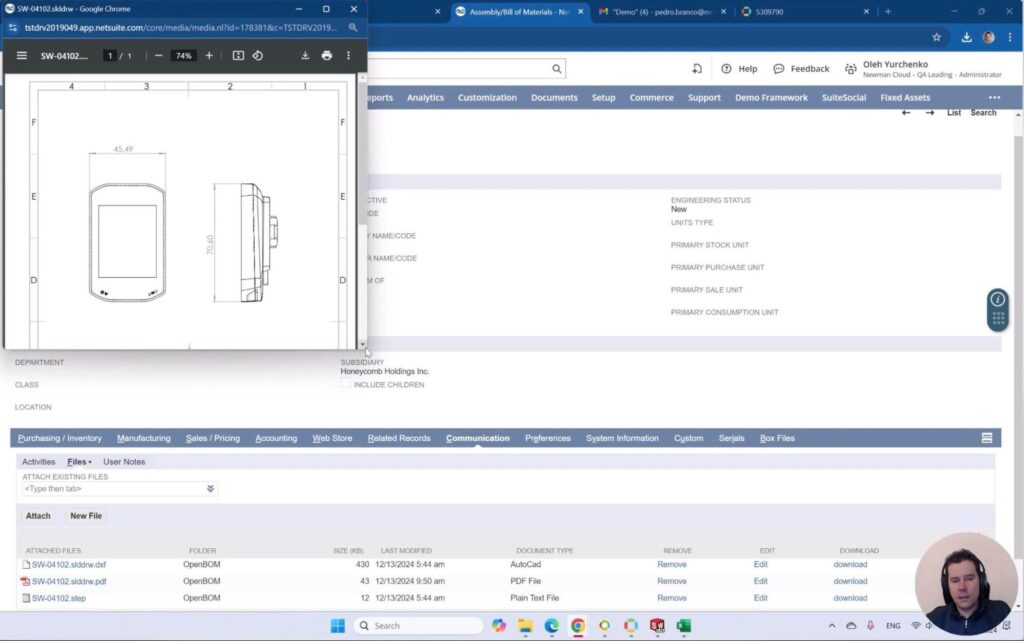

Manufacturing BOM in NetSuites includes metadata (BOM) including visuals (images).

Note, seamless integration to support CAD files transfer to Oracle NetSuite.

Video Demonstration

To see this process in action, watch our detailed video demonstration. The demo walks through each step of the integration, showcasing how OpenBOM captures design data, manages changes, provides direct access to engineering data in NetSuite, and synchronizes EBOMs with MBOMs. This hands-on walkthrough highlights the ease and efficiency of creating a connected lifecycle process.

Key Values of Integration

The integration between OpenBOM and Oracle NetSuite delivers several important benefits. By automating the flow of information, teams can reduce delays and make faster decisions with access to up-to-date information, improving collaboration and reducing errors. Additionally, automating data synchronization eliminates manual data entry, reducing risks and freeing up valuable time for strategic work.

Conclusion

Building a connected lifecycle process with seamless ERP integration is one of OpenBOM’s core value propositions. By connecting engineering and business systems, OpenBOM enables companies to coordinate faster, accelerate development processes, and make engineering data available to business teams early in the product lifecycle. This not only optimizes supply chain and ordering processes but also ensures a smooth transition from design to manufacturing and finance.

Whether you’re working in SolidWorks (or other CAD systems) and Oracle NetSuite, OpenBOM provides the tools to streamline your workflows and drive operational efficiency. Start leveraging the power of integration today and take your engineering and ERP processes to the next level.

REGISTER FOR FREE to check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.