A few decades ago manufacturing companies were developing products, building them, and shipping them from the docking lot. Now, manufacturing companies are shifting their business models into services. We used to buy products (actually we still do), and we can still go and buy a computer, sofa-bed, or refrigerator (you name it) but the business environment around these products is fast moving forward.

My first exposure to services was when I learned about Michelin Fleet Solution. Here is the case study about how Michelin moved from selling tires to providing services. Two decades later, we can see many companies moving from selling products to selling services (kilometers, hours, electricity, computer time, etc.).

Data Management for Service and Maintenance

What does it mean for manufacturing companies and how product development and service must be organized? We are hearing from many companies that they need to have better support to manage data about products that are sold to customers. It is needed to manage actual data about each customer product instance, what’s available, and the ability to manage revisions and changes for each of these product structures independently.

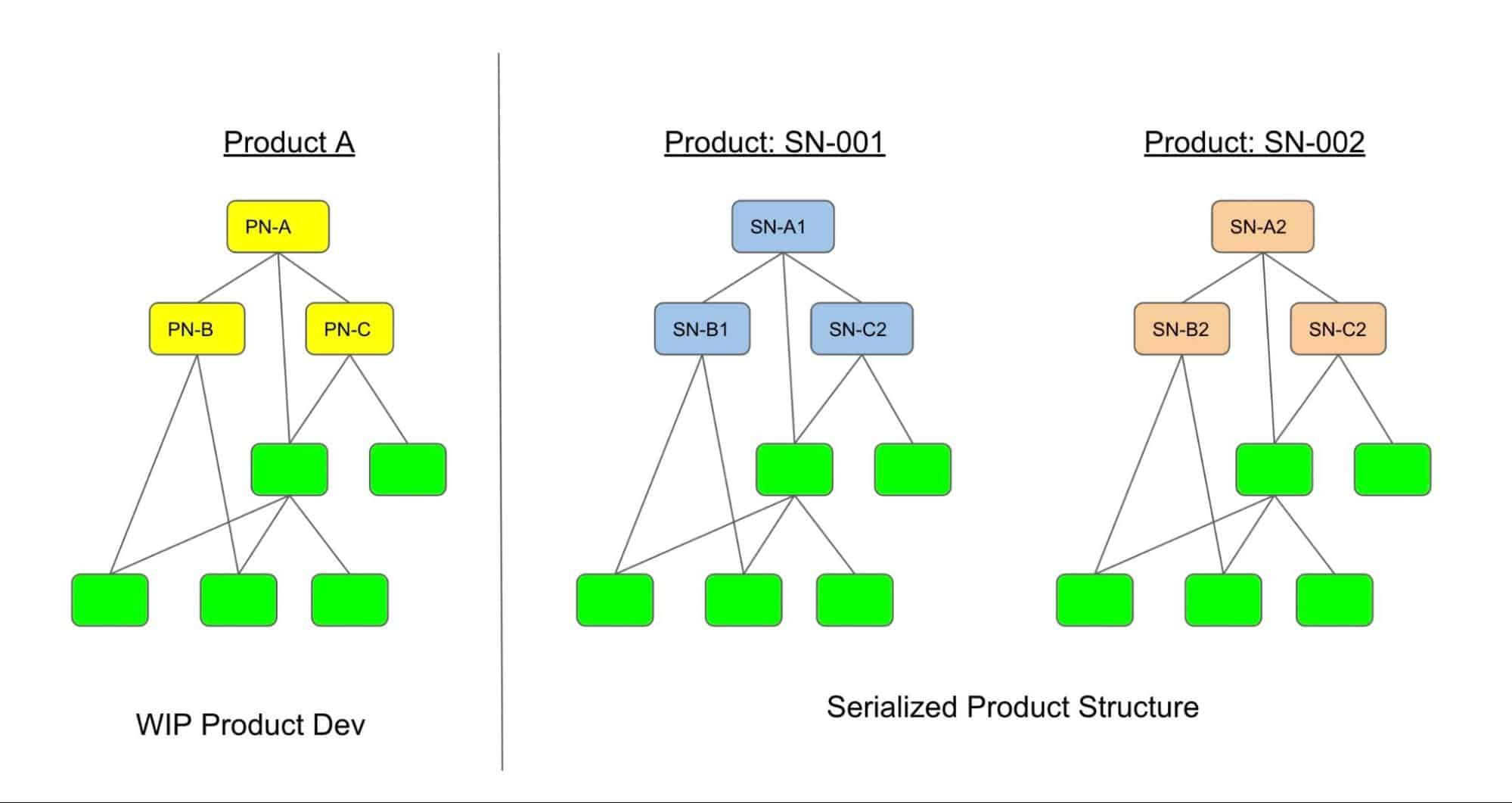

The following picture gives you an idea of how data structure can be organized. The left side of the picture shows as-planned (or engineering) product structure (Product A) and 2 structures on the right belong to two serial numbers of the product (SN-001 and SN-002).

The BOMs on the right side are called serialized BOMs. An important point about serial BOM is that they might have a subset of information that is serialized and another subset of information that is remaining the same. In the picture, 3 items in the product have serial numbers and other items don’t.

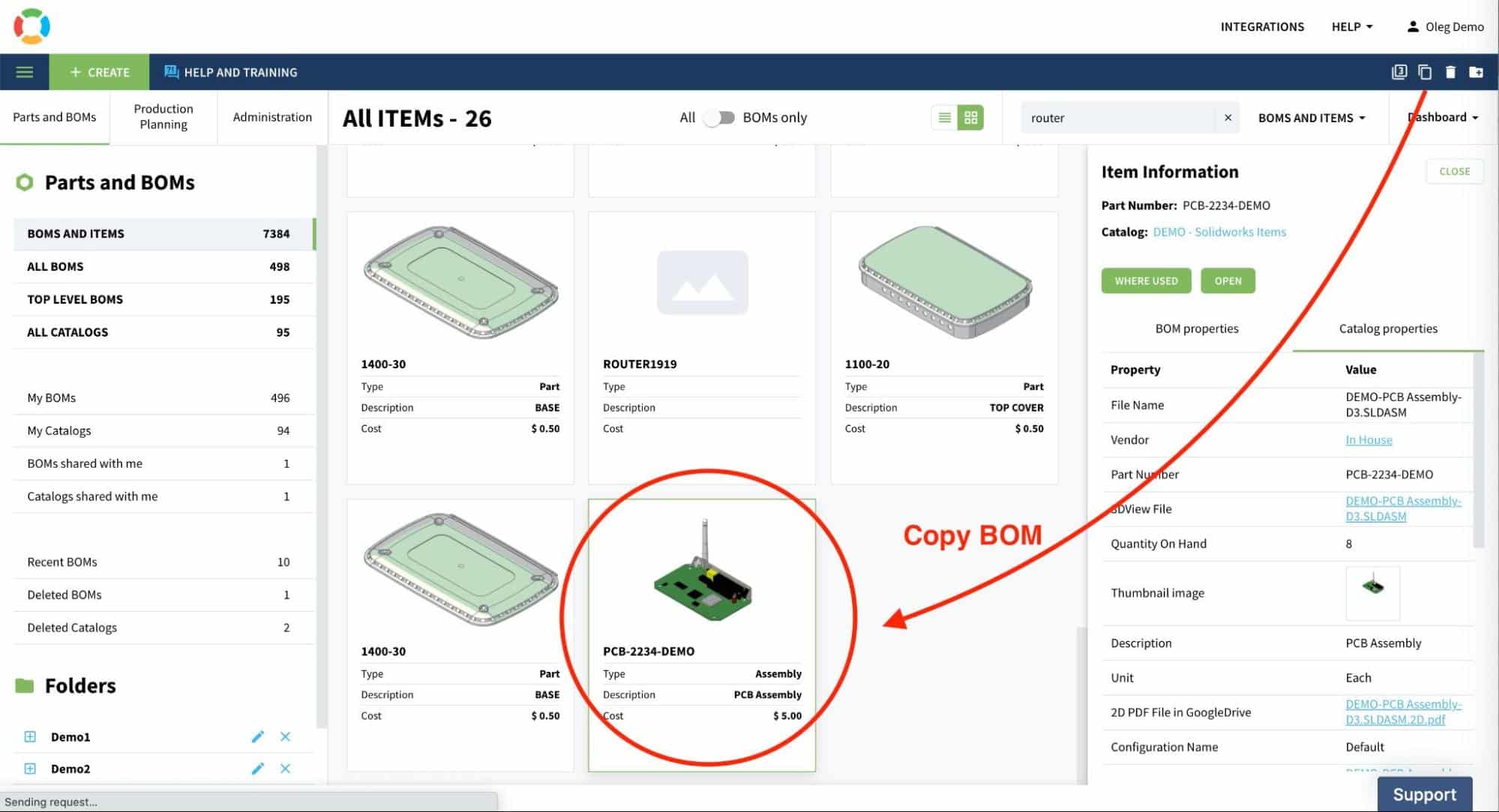

Copy BOM Function

The way to serialize BOM in OpenBOM is to use the “Copy BOM ” function available via the dashboard. Each multi-level BOM is represented by a hierarchical structure of single-level BOMs. Copy (serialization function) works for each level independently. So by using the copy function you can control how many levels to synchronize. REST API can be used to automate these functions for the moment.

Once the BOM is copied you can remove all Items that you don’t want to have in serialized BOM.

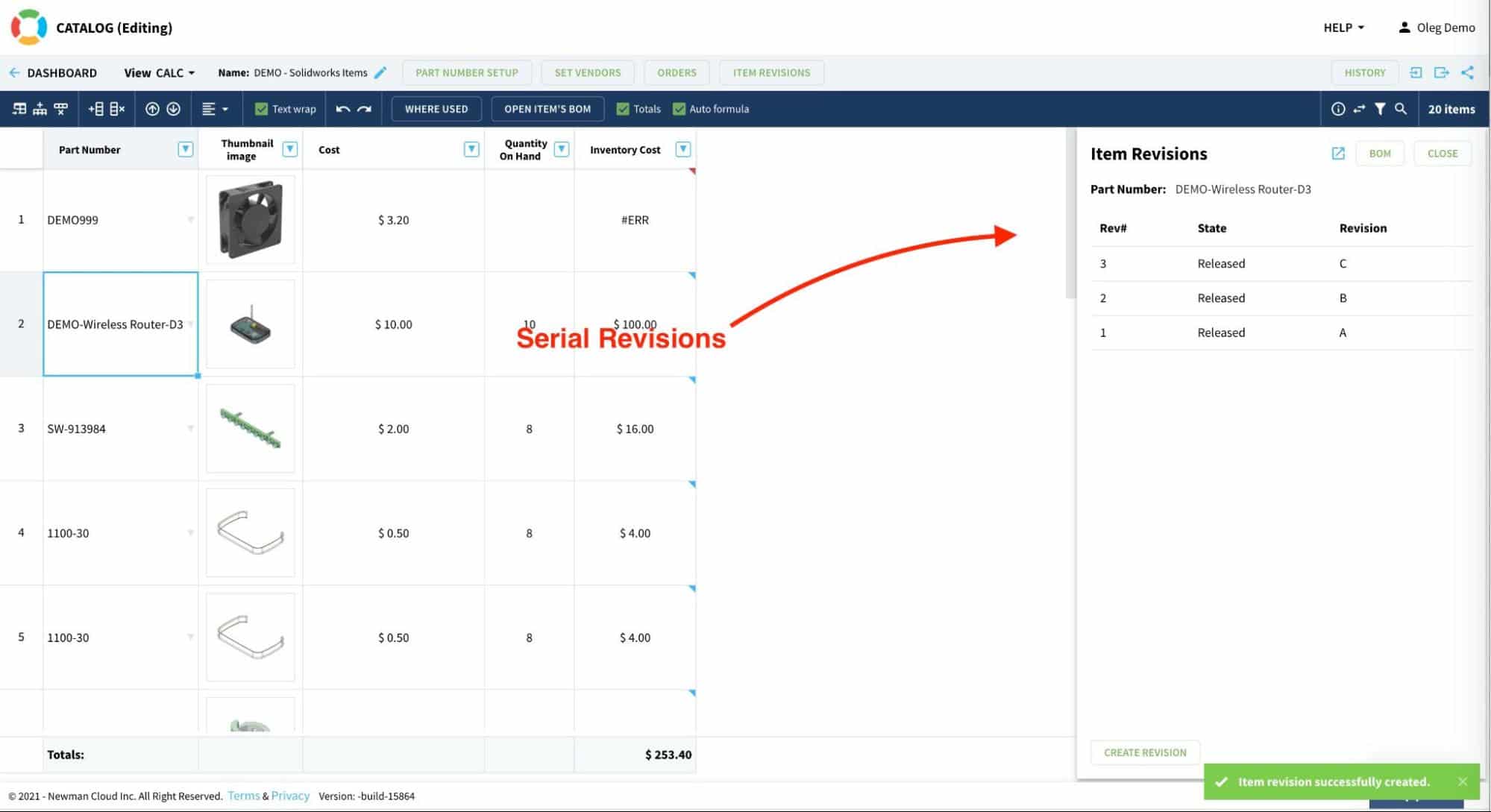

Revisions and Changes in Serial BOMs

Once BOM is serialized, it is a fully functional BOM that allows you to manage revisions and keep the history of all revisions.Conclusion

OpenBOM’s flexible and cloud-based data management architecture allows it to organize Bill of Materials separately for engineering, planning, and serial BOMs. But separating them is only one part of the solution.

OpenBOM Revisions allows you to manage changes in serial BOMs independently of the engineering and planning BOMs. By doing so, you can manage the lifecycle of the customer’s product and record each change and maintenance performed on that product. Even more, getting access to all these customers’ BOMs gives you control over an entire set of products that allows you to plan how to repurpose and dispose of these products in the future.

Want to try OpenBOM? Then Register FOR FREE and start your 14-day trial to test all of OpenBOM’s Features.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.