The importance of accessing the correct information has never been more critical than it is today. With many people in different roles, manufacturing companies are desperately looking for ways to seamlessly access information across the organization. Imagine you are engineering and manufacturing a product and need to buy components. Ensuring that engineering and manufacturing teams are looking at the same records is a must. However, many organizations operate in siloed systems, where procurement agents and design engineers view the same records in different databases or, even worse, in different spreadsheets. This disjointed approach leads to inefficiencies, errors, and costly delays.

OpenBOM’s Seamless Data Access Solution

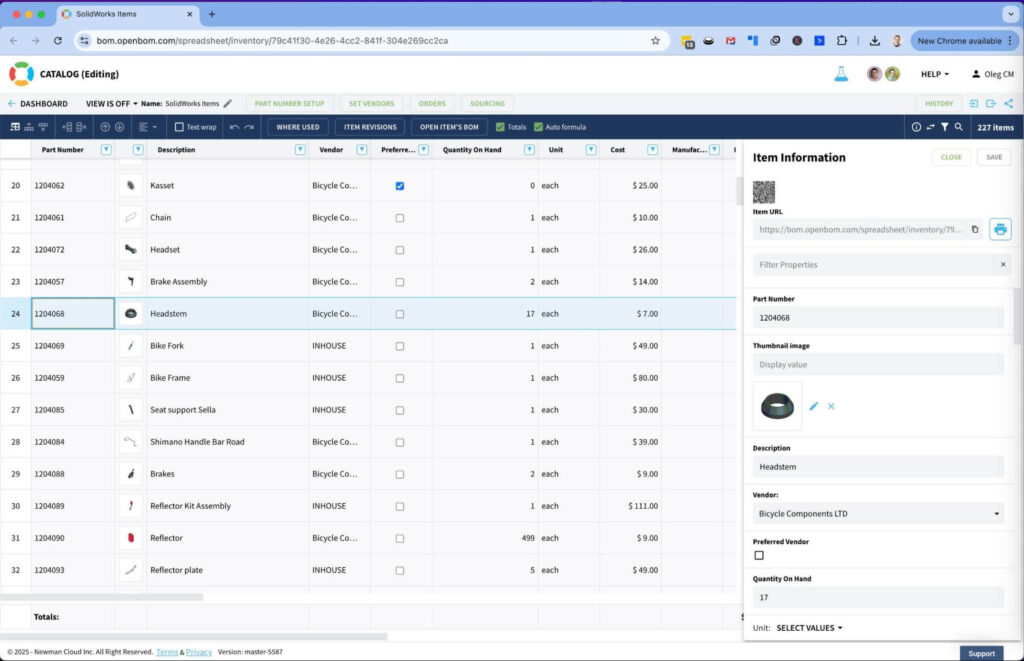

At OpenBOM, we provide a seamless yet robust and powerful mechanism to bring data from multiple sources into unified records, making them available to everyone in the organization. With a simple, flexible, and robust data model, OpenBOM makes it easy to develop highly tailorable models to fit all record (item) types while applying specific views (engineering, procurement, etc.). This ensures that every user gets access to the right information in the right context.

Approaches to Accessing Information

To illustrate how OpenBOM streamlines information access, let’s explore a few approaches that make part data available for procurement teams:

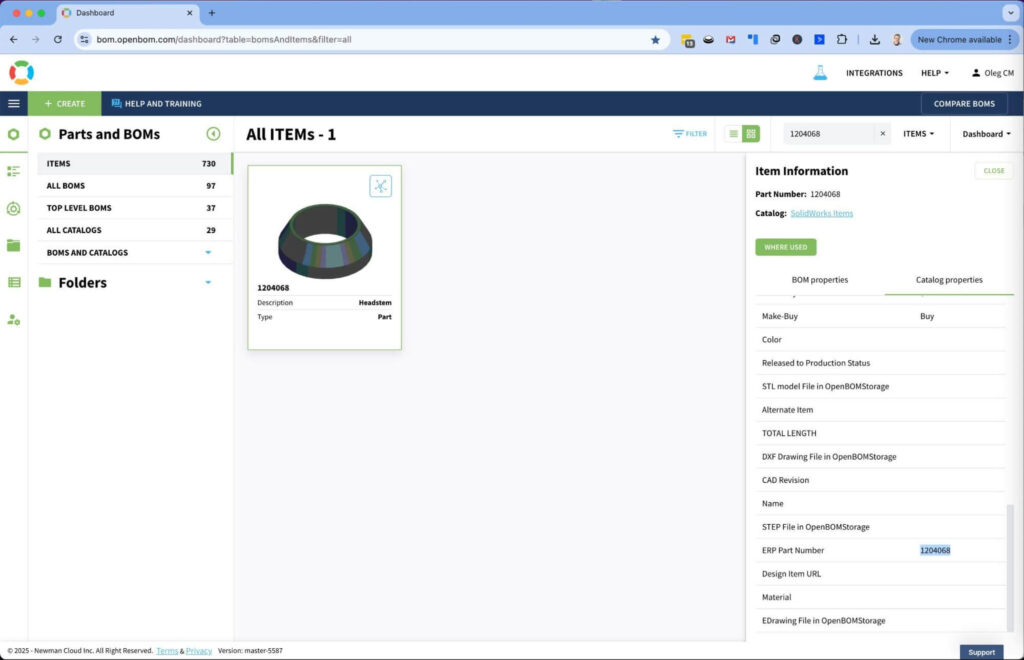

1. Items Dashboard with Simple Full-Text Search

This is the easiest and most intuitive approach. Users can perform a full-text search by part number, description, or any keyword, instantly retrieving a visual representation of the item in a unified form. This eliminates the need to dig through multiple sources to locate relevant part data.

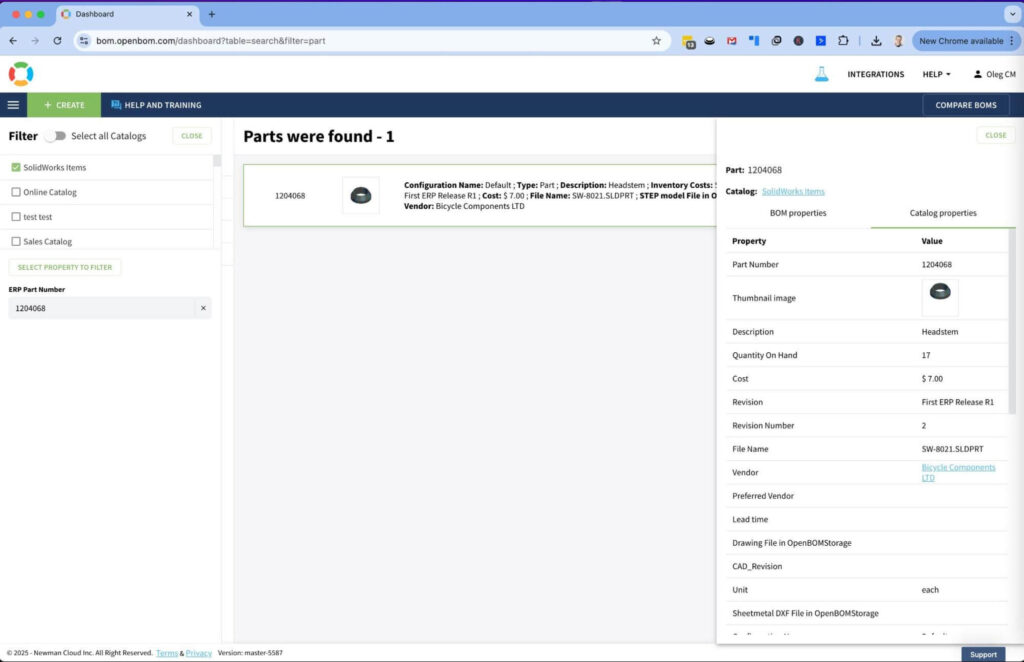

2. Item Advanced Search with Faceted Filters

For a more sophisticated experience, OpenBOM provides an advanced search mechanism with faceted filters based on item attributes. Users can refine searches by specific catalogs, ERP numbers, material types, or vendor details, ensuring precise and quick access to the right information.

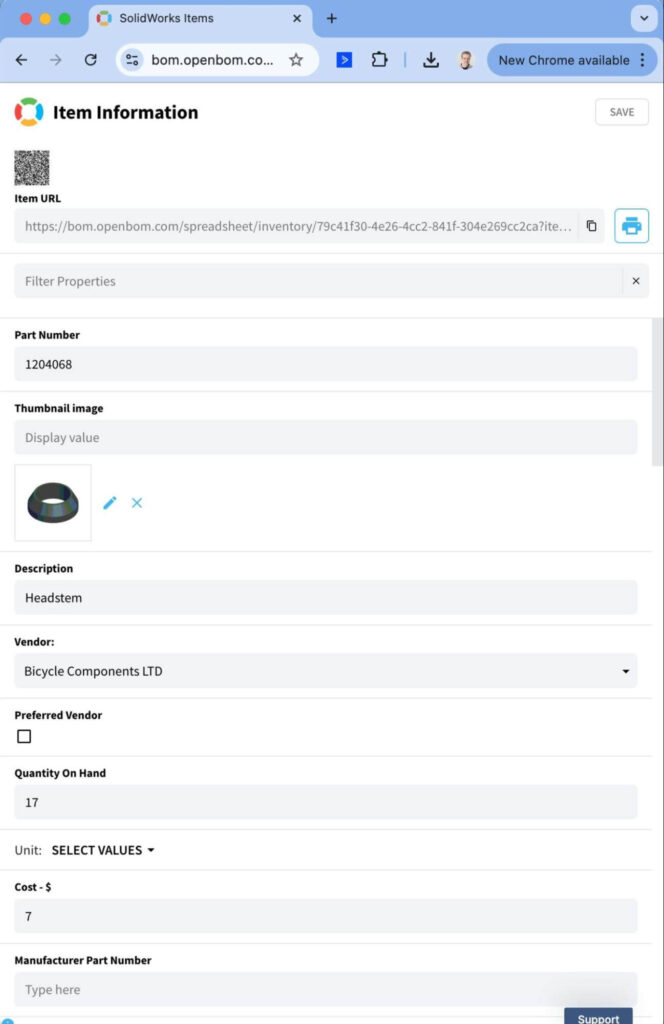

3. Single Item URL for Quick and Consistent Access

Each item in OpenBOM can be accessed via a stable, shareable URL. This ensures that users across different systems can retrieve the same information effortlessly. The unified user experience is consistent across both desktop and mobile browsers, allowing quick reference and collaboration.

And here is a single item direct URL access

Conclusion

OpenBOM provides a robust mechanism to grant access to critical part information for users across an organization. With these tools, no one will ever need to ask, “What is this component? Who is the vendor? Where can we buy it? Where can we get related files (STEP, PDF, etc.)?”

Want to experience it for yourself? REGISTER FOR FREE and check OpenBOM out today!

Best,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.