If you use SOLIDWORKS to design products, one day you will obviously need to create a Bill of Materials for what you want to build. As every professional 3D Mechanical CAD system, SOLIDWORKS gives you a way to create a Bill of Materials (engineering) table in a drawings as well as to export BOM to Excel.

While this is very much standard, it doesn’t help you when you need to calculate the cost, mass or plan purchasing. Also, sending Excel and Drawings to a shop or to a contract manufacturer is prone to many mistakes.

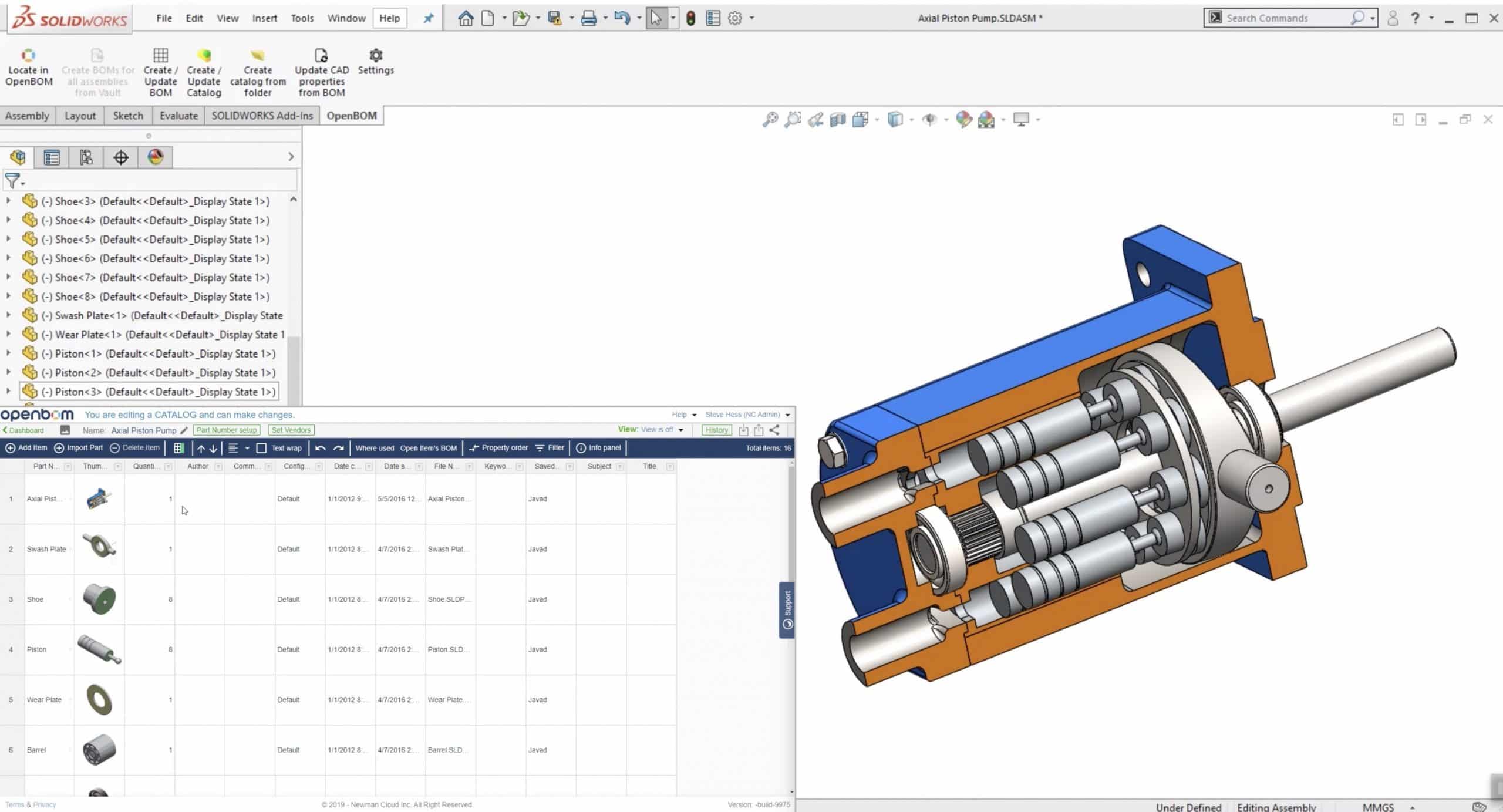

OpenBOM is coming to help you. To make it really easy, OpenBOM created integrations with all CAD systems allowing you to collect information engineers and organize it in a way that allow you to manage data about all your parts (standard, fabricated, outsourced) as well as product structure.

Below, you can find a typical scenario to follow in order to organize the data and create a first BOM from Solidworks. I assume, you already installed OpenBOM Add-in for Solidworks. And here are the steps:

- To configure OpenBOM Add-in using settings and define templates

- Create an OpenBOM catalog from the assembly. Add business parameters you don’t want to store in Solidworks (Eg. cost, manufacturer and supplier names.

- Create a catalog – this is a central place to store data about parts

- Create a BOM – it is a structure that helps you to capture usage of parts in this particular BOM

- Connect BOM to a catalog to create a complete data representation of product structure.

Please watch the video with step-by-step instructions.

Conclusion.

Establishing product structure including information about the parts, usages and other business information (Eg. cost, supplier) is a great step to improve the way you work in product design and manufacturer. OpenBOM Add-in for Solidworks allows you to capture data about BOM and keep related information closed, but noto messed up with multiple Excel files.

OpenBOM Add-In for Solidworks is FREE and it is available with any OpenBOM subscription today.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.