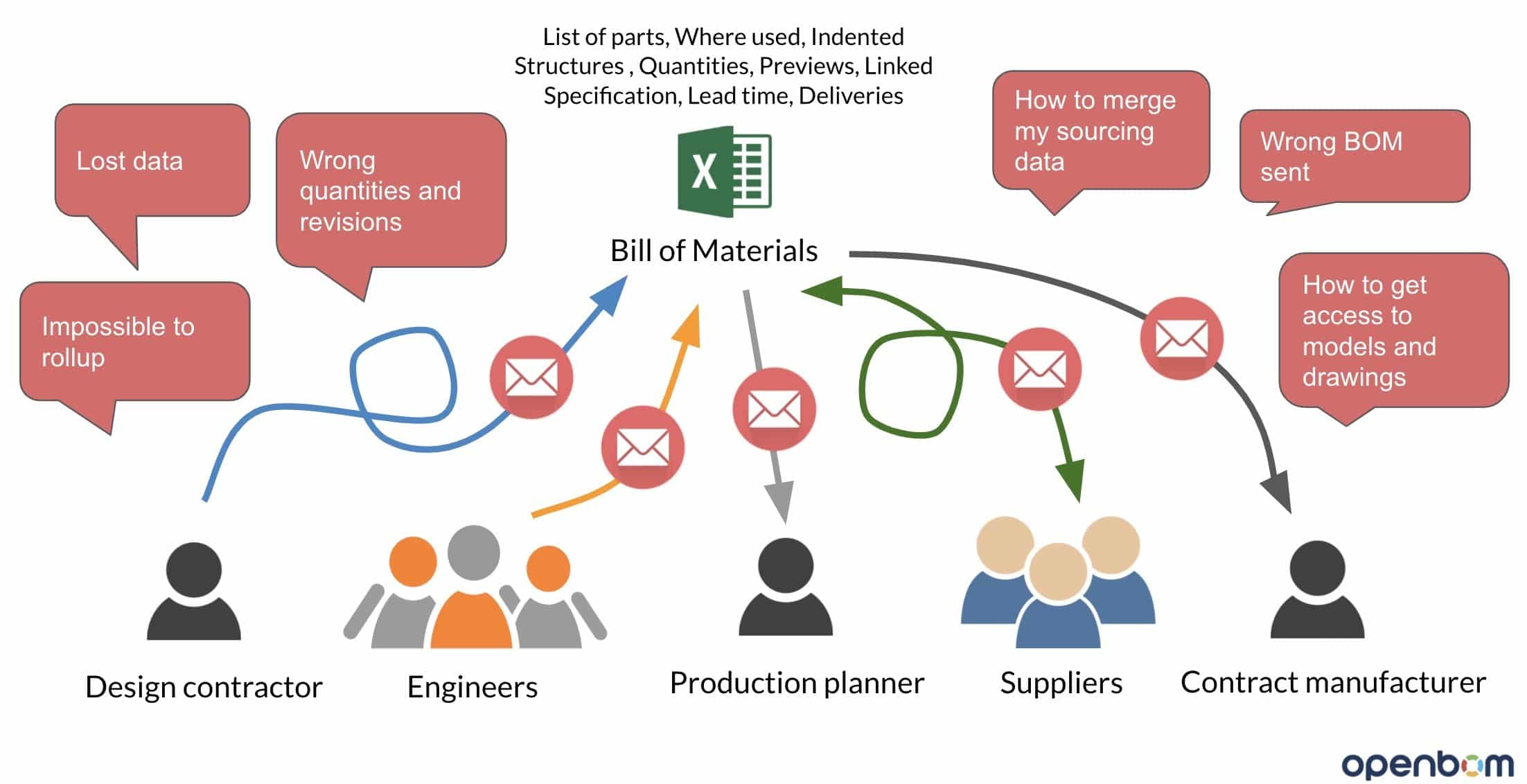

A spreadsheet was never built for PLM, BOM management, and collaboration. In a typical process of connecting engineers, contractors, production planners, suppliers, and contract manufacturers, the Bill of Materials is the lifeblood that allows this process to keep going. The process is not simple and can bring many challenges.

When Excel and email are the ways to communicate, companies can face tons of challenges – lost files, impossible to rollup cost, wrong information manually places in Excels, merging information from multiple suppliers, sending wrong files to contractors, getting access to drawings and many others.

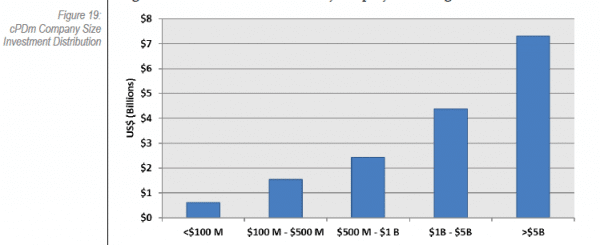

While PLM software vendors are talking about PLM technologies as a “single version of the truth” for manufacturing for ages, this PLM systems and implementation are still the unachievable dreams for many manufacturing companies. Especially when it comes to small and medium manufacturing companies.

In my recent Beyond PLM blog – PLM for SMB: Business, Market and Numbers, you can find an interesting data point about the distribution of PLM sales between companies of different sizes.

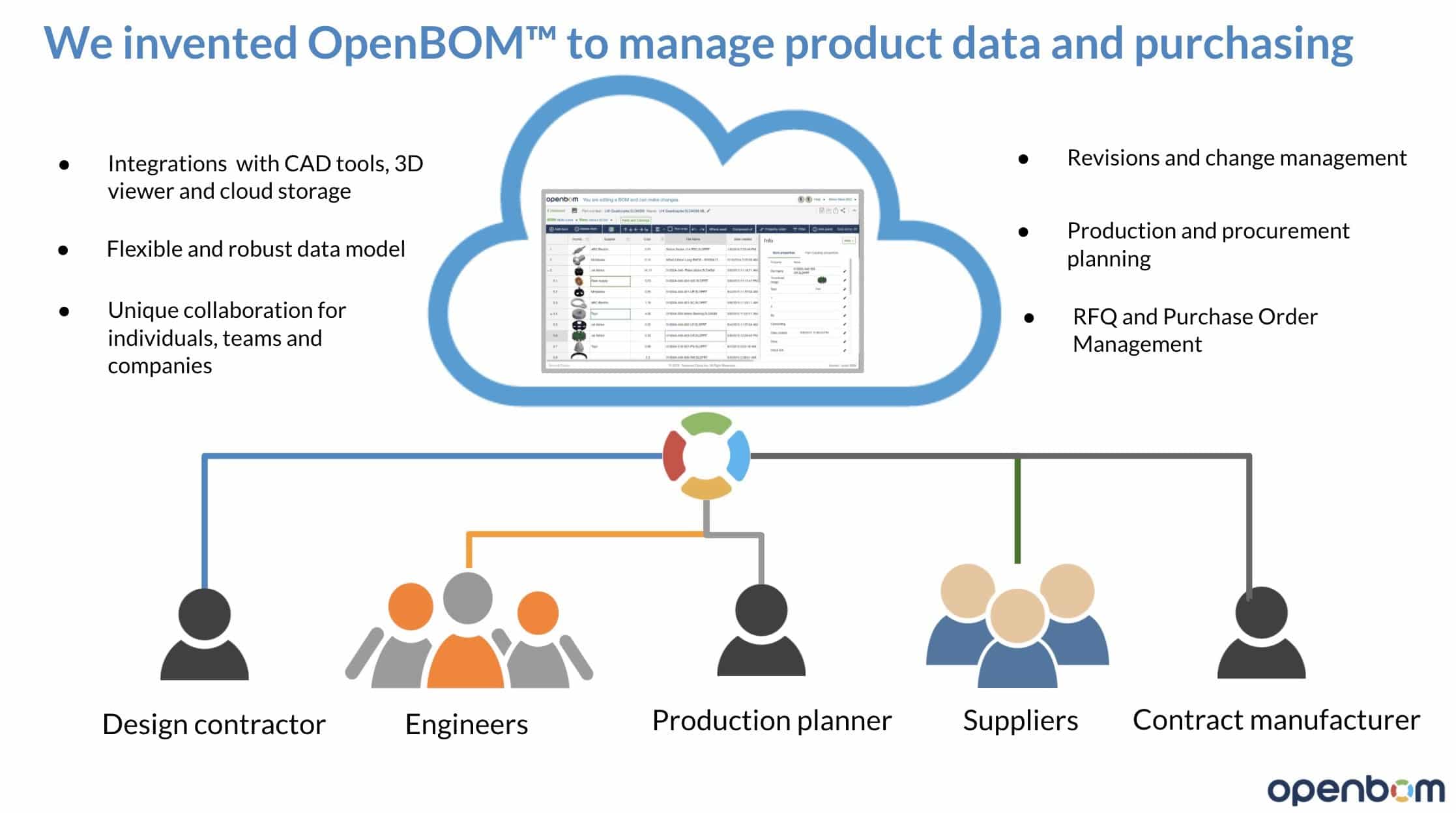

This is a reason we built OpenBOM – to solve the problem of communication and data management for small and medium-size manufacturing companies to optimize their production process, managing data and communicate between teams and people located across the globe.

OpenBOM is using modern cloud technologies to solve data management challenges and provide subscription business models with unmatched ROI. Check the subscription plans here.

Conclusion

OpenBOM provides unique multi-tenant data management technology and out of the box process to communicate between engineers, purchasing planners and production. Real-time simultaneous collaboration and flexibility, combined with support for CAD and integrations, out of the box formula and calculations process can give you a way to transform the processes in a matter of days. Check what OpenBOM customers are saying about their experience here.

Read OpenBOM full OpenBOM Engineering story.

Check what OpenBOM can do today subscribing to OpenBOM here or request a trial version.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.