In any business, time is money. The more time an organization spends on tasks that don’t generate revenue, the less money they have to invest in growing its business. Engineers like to get engaged in the design and actual engineering jobs rather than manage data and organize Excels. From my experience of working with many engineers, managing data will be the least favorite activity for engineers. No one really likes to manage data. BOM in Excel is one of these activities. Managing BOMs in Excel is one of the most time-consuming non-design tasks.

Poll: How much time is wasted managing BOM in Excel

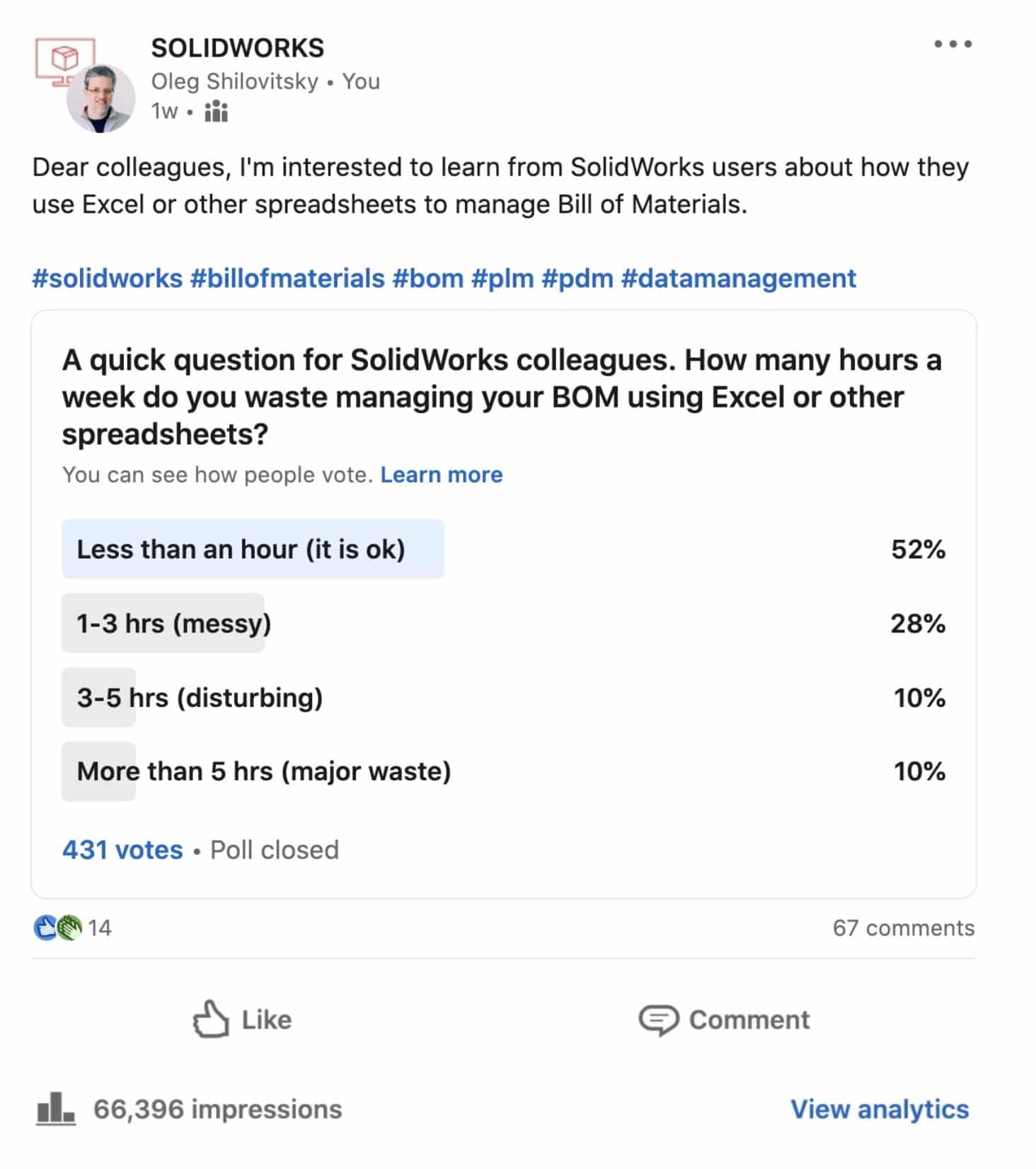

We wanted to learn more about how much time engineers spend managing BOM in Excel. Without any chance to provide a systematic answer, we decided to create a LinkedIn poll and publish it in a large Solidworks LinkedIn user group with more than 100K members. We’ve got pretty interesting results. With more than 60K impressions and more than 400 votes, it can give you an idea of how much time is spent and what engineers actually think about it. In the picture below you can see the results of the voting.

Roughly half of the respondents said that they spent less than an hour and it is not a big deal. That was not a surprise. SolidWorks is known for a very nice BOM to Excel export and I know, from experience, that for many engineers exporting BOM to Excel is the end goal. Then they pass it to other people in their organization that need to take care of managing these BOMs and this amount of work is not counted by engineers.

It was very interesting to learn that 38% of respondents are spending 1-5 hours every week in Excel and this is messy and disturbing. The last 10% spend more than 5 hours a week and this is a total waste

What did we learn from comments and conversations?

I’ve been talking to many engineers during this poll online and offline to understand where the time is spent and how to help engineers to streamline their work. Here are the top three things where we believe companies are failing and, as a result, wasting time and money using Excel as a data management tool.

- Many engineers are not aware that there is a better way to manage BOMs rather than export files from SolidWorks to Excel and send them downstream using emails.

- Export data actually takes very little time, but processing data is where real waste is happening.

- Updates are very painful and once data is exported, it is very difficult to manage updates.

- Engineers prefer to keep all information in Solidworks (including non-CAD items), which can simplify merges, but bring a lot of unnecessary data to the CAD system.

- Managing non-CAD business data using CAD storage (eg. SolidWorks) can make purchasing decisions very hard.

- There is no good visibility of the data managed using Excel, which is a big downside for all companies.

Conclusion

The amount of time engineers spent in Excel is gigantic. However, the problem is much bigger and deeper. While the visible time engineers spend managing BOM in Excel is between 1-5 hours per week, companies are losing money on mistakes, wrong Excel file sharing, wrong data used by different departments, and many other problems that are caused by using Excel as a data management tool.

How we can help? OpenBOM provides out-of-the-box, simple, and easy cloud-based tools that can simplify the work of every engineer and help organizations to get aligned and streamline data management including parts, BOMs, documents, and purchasing process.

REGISTER FOR FREE and check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.