In the world of business, there is always a need to stay ahead of the curve. For small and medium businesses (SMBs), this can be a daunting task, especially when it comes to digital transformation. However, with the right education and training, SMBs can make strides in this area and compete with larger organizations. Transformation involves many areas such as technology, process improvement, marketing strategy, and more. It can be difficult for any organization to keep up with all of these changes, let alone SMBs. That’s why it’s important for these businesses to have access to resources that will help them navigate through this digital age. Education and training are two essential tools for SMBs seeking success in digital transformation.

Over the weekend, my attention was caught by the interview of Peter Bilello, CEO, and President of CIMdata, a leading analytical and consulting company helping industrial companies with modern trends in PLM education and transformation. Jos Voskuil, PLM coach, also known as Virtual Dutchman was talking to Peter. You can read their conversation here – PLM and Education. My favorite passage is about the difference between education and training:

It is important to differentiate between education and training. Where education is a continuous process, training is an activity that must take place at the right time. Unfortunately, we often mix those two terms and believe that people are educated after having followed a training.

And I really like this Albert Einstein quote – Education is not the learning of facts but the training of the mind to think, which I found super critical when it comes to how engineering teams and manufacturing companies should approach the process of adopting new software. Let me talk more about it and share some ideas and examples.

At OpenBOM, we worked with thousands of small manufacturing companies helping them to move from the world of spreadsheets documents into a digital world of connected information. In this article, I want to share some of our learning and examples of companies using OpenBOM educational resources to transform themselves into a future of digital business.

Education and Training are Vital for Successful Implementation

At OpenBOM we learned is that many companies are looking at how to get rid of old fashion Excel-driven data management scenarios to adopt modern product lifecycle management solutions. However, the process is hard for them. And the software doesn’t play a key role in the process. It is all about how to bring the company’s educational level up from the environment where they think about documents and Excel to the environment where the company thinks about data, connected information flow, and process optimization.

We do it by applying two processes. The first is the educational process which is done by OpenBOM content, blogs, videos, online events, and social media activities. Then the first step in our onboarding experience comes – a company is getting aligned on the main concepts of data management and information workflows. The second step is actually training and it is focused on how to help the company to set up an action plan of cleaning their data, setting up the environment, and planning their implementation steps. Read more about the OpenBOM Onboarding Experience.

Why SMBs Struggle with Transformation?

One of the reasons why SMB companies struggle with the adoption of digital methods of working is related to extremely stressful environments and organizations. The lack of resources is a fundamental problem. There are no IT and dedicated people to manage systems, people are wearing multiple “hats”, the delivery time is always stressed and there is no time to learn and do the planning. This is how we found that providing an online experience with all information can balance well with the companies’ willingness to progress. OpenBOM unique environment, technologies, and products combining SaaS platform, the flexibility of spreadsheets and educational resources made a switch possible

Benefits and Customer Stories

Here are some examples of customers that were educated and trained using the OpenBOM onboarding service. Read more stories here – OpenBOM customers.

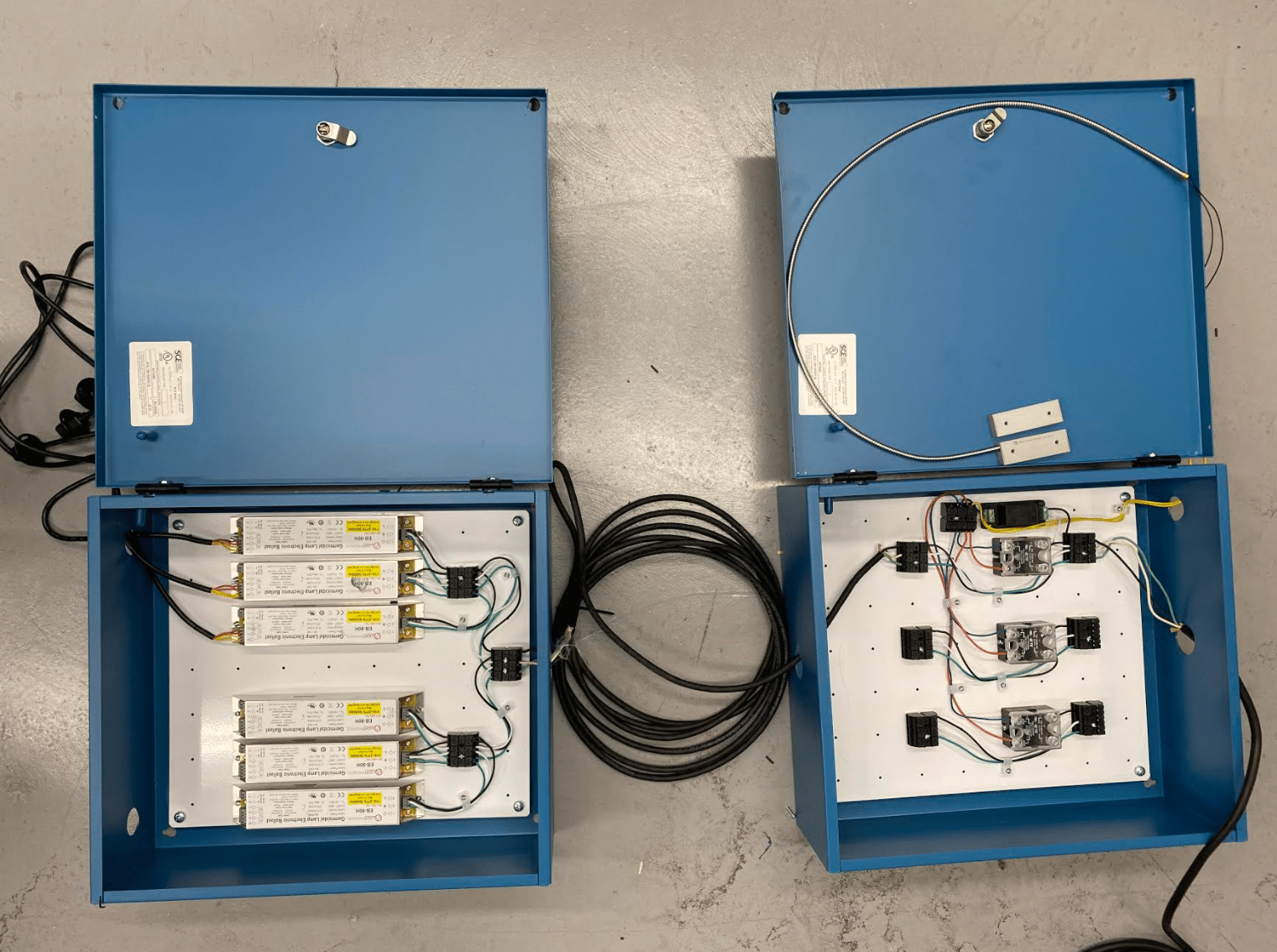

PURO Lighting

Lakewood, Colorado’s PURO Lighting recently completed OpenBOM onboarding and Mechanical Engineer Alex Wamain had this to say about the experience:

“We at PURO Lighting are very pleased with the OpenBOM onboarding experience. The training was catered for our needs and was able to touch on all the specific functions that will make our lives easier when it comes to building our database and bills of materials.”

PURO lighting is a manufacturer of disinfecting lighting technology designed to help protect people’s health and promote wellness wherever they may gather.

As a newcomer to OpenBOM, we worked closely with their team to configure OpenBOM while making key decisions designed to improve their overall business process.

PURO Lighting’s team was prepared for the live sessions with sample data and process requirements ready to go.

“We recommend the annual subscription as the onboarding ensures all members of the team are familiar with the software and have solid foundational knowledge. Avoiding time wasted teaching ourselves is worth the upfront cost,” says Alex.

Read more about the PURE Lighting story.

Grand Craft

“Very shortly after purchasing OpenBOM, we were contacted by OpenBOM Director of User Experience, Steve Hess. Steve worked with me and my team to develop and deliver an onboarding experience based on our needs”, says Jeff.

The OpenBOM Onboarding Experience is a hybrid self-paced/instructor-led experience involving a detailed questionnaire followed by two dedicated live sessions designed to meet the exact needs of the customer.

“Steve helped us understand our own process and even exposed a few areas we could improve”, says Jeff, “The sessions were extremely specific to our needs and goals for OpenBOM.”

OpenBOM onboarding is based entirely on the customer’s needs and actual data sets. By the end of the last session, customers are working with their own data, properties, vendors and making real BOM and Purchase Orders!

Read more about the Grand Craft experience.

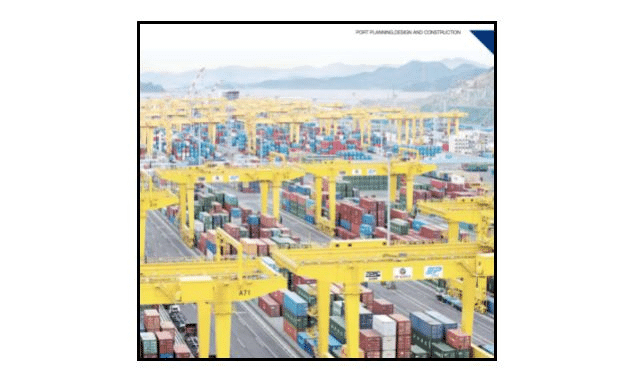

ABB Marines

ABB Port Systems and Services delivers automation and electrical systems for container and bulk cargo handling – from ship to gate and has recently deployed OpenBOM.

“As the OpenBOM administrator at ABB – PSS, the OpenBOM onboarding service provided me and my team with the necessary skills to properly implement our process within OpenBOM,” says ABB Ports Systems and Services division Materials Manager, Eric Herms

“Steve and his team have extensive design and manufacturing skills and went right to the core of our implementation needs. Offering their expertise whenever we needed it and providing support with fast response times. The experience has been vital to our success with OpenBOM and we are excited to bring this new software to our organization”.

Read more about ABB’s onboarding experience.

Monarch Tractor

Monarch Tractor is based in the rich farming community of central California and is bringing innovative and healthy solutions to the farming community in the form of fully electric tractors and recently subscribed to OpenBOM to help them do it.

As the design team at Monarch was crafting a new approach to the old problem of part numbering and CAD, Hardware Engineering Lead Eddie Smith and I tailored the first onboarding sessions specifically to numbering as it was foundational to their process.

“OpenBOM’s Solidworks CAD integration tools will help us streamline our product development process as we move towards mass production. Big thanks to Steve for his in-depth product knowledge of OpenBOM and help in getting our system properly configured to roll out to our full team”

Read more about the Monarch Tractor experience.

Conclusion

For many years, product lifecycle management was an achievable goal for many manufacturing companies. The need to invest in IT, management resources, and long implementation and training cycle were clear showstoppers. Companies for years were silently voting to spreadsheets as the second-best PLM software. At OpenBOM we decided to charge the trend. We combined a unique technological platform using modern data management and SaaS tools with an online educational experience and training process. This is how we got x2.5 Y2Y growth at OpenBOM for the last 3 years.

Learn more about how OpenBOM can help – REGISTER FOR FREE and start a 14-days trial to explore all OpenBOM features.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.