Integration with ERP is an often requested feature in OpenBOM. While when it comes to ERP integration one size doesn’t fit all, there are few general principles of how data can be transferred. One would be called bottom-up when you will take all assemblies on the lower level of your BOM and transfer it to ERP. Another option is when you can take an entire assembly structure and push it to ERP.

The main advantages and disadvantages of both approaches are related to simplicity and the need to create change orders.

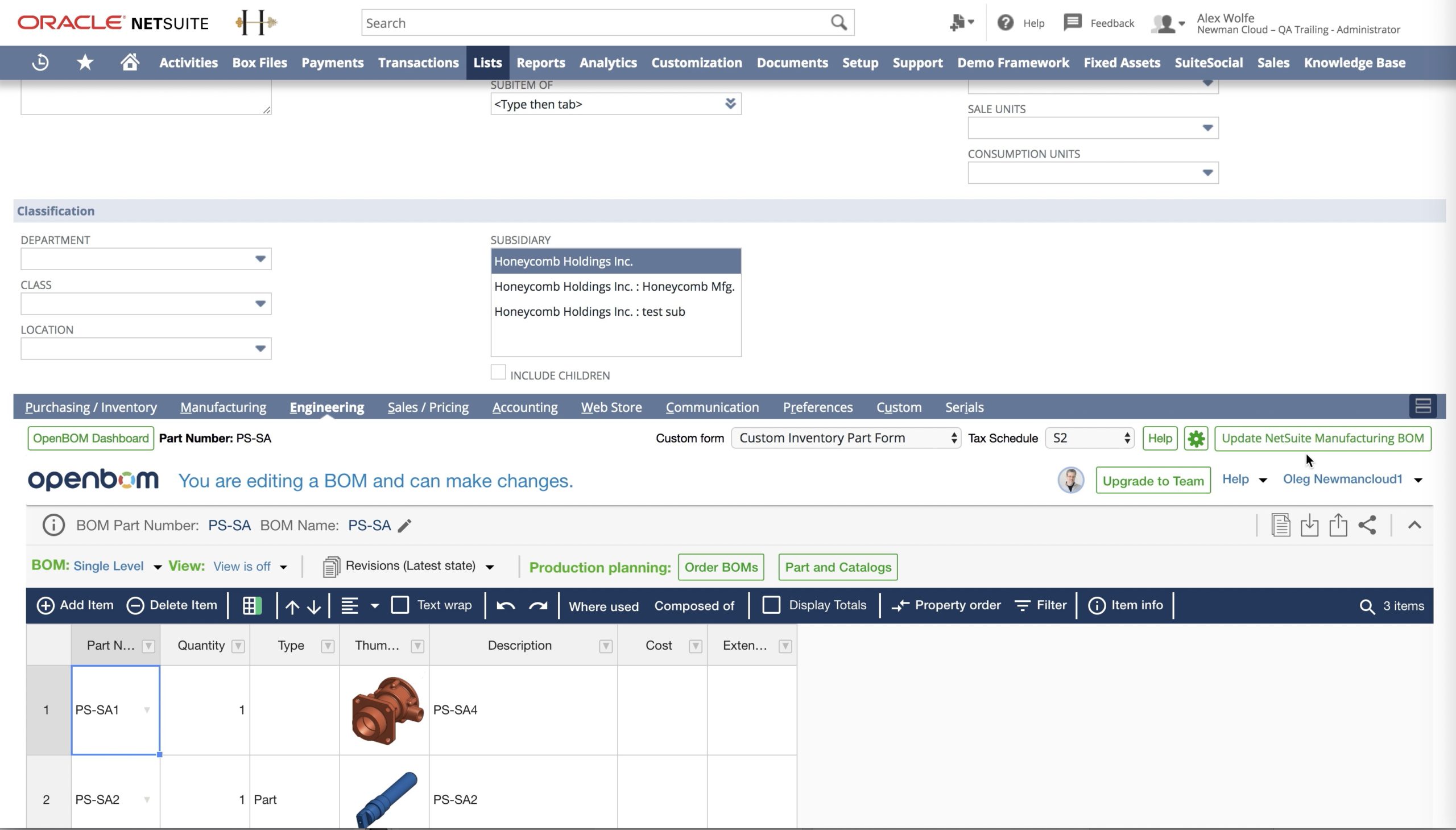

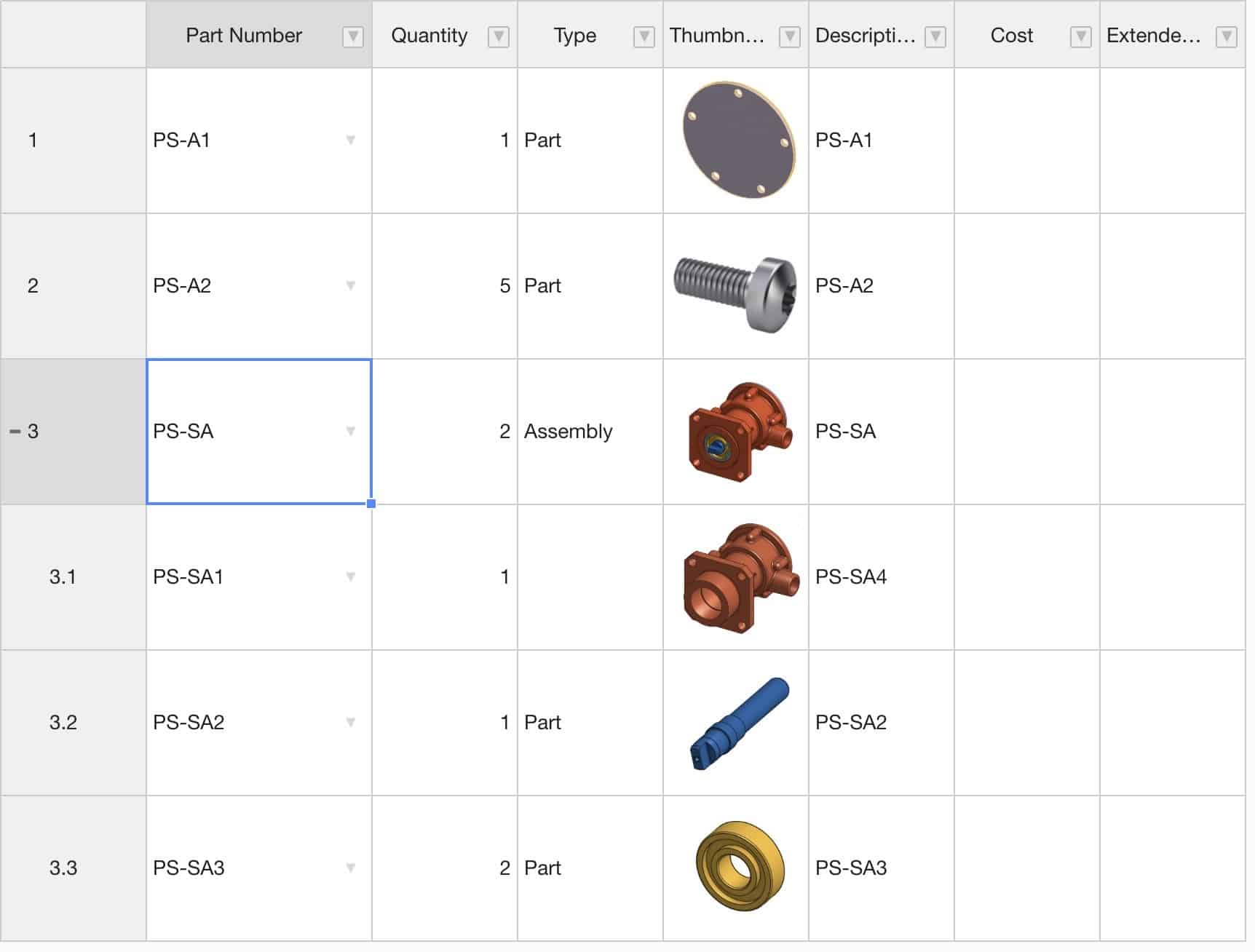

Today, I’m going to show you the simplest option when you can transfer Bill of Materials of the following assembly and sub-assembly bottom up.

The transfer will be done in 2 steps. First, we create an item for PS-SA and later we create an item for PS-A. The following video gives you an idea of how it can be done.

Next time, I will show how you can transfer an entire assembly with sub-assemblies to Oracle NetSuite.

Conclusion

Transfer of data from OpenBOM to ERP (Oracle NetSuite) can be done bottom-up and top-down. OpenBOM supports both simple and advanced manufacturing mode in NetSuite. In this example, I used a simple BOM. Advanced will require to create a revision of the item to transfer the BOM. Stay tuned for part 2 of this article.

Check what OpenBOM can do today subscribing to OpenBOM here or request a trial version.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.