In today’s data-driven world, seamless integration and efficiency are paramount. An integration of the two most important siloes in every manufacturing company is a big deal. Companies are spending tens of thousands of dollars to create seamless process integration between engineering and manufacturing.

At OpenBOM, our strategic goal and vision is to support seamless integration and collaboration between multiple services and processes. You can learn more about OpenBOM integrations online. While OpenBOM supports multiple integrations, we always wanted to build a special dedicated combination of tools that targets a specific group of customers. In our case, we’ve been talking about the underserved market of SMB/SME companies. And this is how we came to our Deskera and OpenBOM partnership.

PLM and ERP integration is a central focus of our collaboration. The partnership between Deskera ERP and OpenBOM seeks to deliver a holistic solution that streamlines critical processes, fosters collaboration and drives innovation in enterprise resource planning and product development.

In my article today, I want to share with you more information about how OpenBOM and Deskera can operate together and manage the entire lifecycle of information starting from CAD design and OpenBOM and ending up with procurement and production.

Manufacturing Maze of Data Complexity

Manufacturing is complex and it requires many actors and companies to work together. What you can see in the picture below, is an illustration of product data and development complexity.

With the introduction of new cloud technologies and web APIs, it is now very possible to build an integration using online tools. And this is what we are going to discuss in this demo – how Deskera and OpenBOM, both SaaS tools can integrate and provide a seamless way to work together.

Engineering to Production Story

In this demo story, we walk through the steps to help you manage design using OpenBOM for Solidworks, extracting all product structures with related files, and sharing this information with production. OpenBOM helps you to create a full product structure (BOM), and manage and estimate cost.

Here OpenBOM is fully integrated with Solidworks.

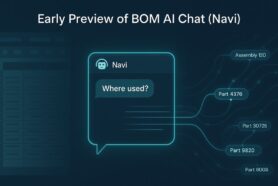

Creating BOM and navigating through the data and all dependencies is a strong element of the OpenBOM user experience.

Bill of Materials includes all the information needed.

This is a place where the handover to Deskera production planning is happening.

Deskera ERP seamlessly continues with product planning, purchasing, work-order, and finance. Until you can finally ship the product.

Purchasing is part of Deskera’s finance and procurement work.

Besides the data handover, OpenBOM and Deskera can manage data visibility such as inventory, cost, and others directly in a design environment. For more advanced use cases we do plan to ECO and MCO interplay and orchestration.

VIDEO DEMO

Watch the recording of the live demonstration in the following video.

Conclusion

The partnership between Deskera ERP and OpenBOM offers streamlined operations, connects engineering processes and product data to enterprise and financial processes already early in the new product development, and realizes our vision of agile new product development processes. It helps to realize the goal of modern manufacturing to establish a seamless and connected data loop between engineering and production.

If you’re looking to streamline your business processes and operations across the entire organization and lifecycle starting from engineering design, CAD work, engineering bill of materials, production and purchasing planning, work orders, and procurement, you need to check OpenBOM and Deskera together.

Please contact our sales@openbom.com to schedule a demo.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.