In the previous article – Day #10 – Design Projects Explained – How OpenBOM Connects Design Files, Data, and Collaboration, we discussed the PDM service provided by OpenBOM to help you to organize CAD and other files as well as to manage engineering design, versions and history of changes.

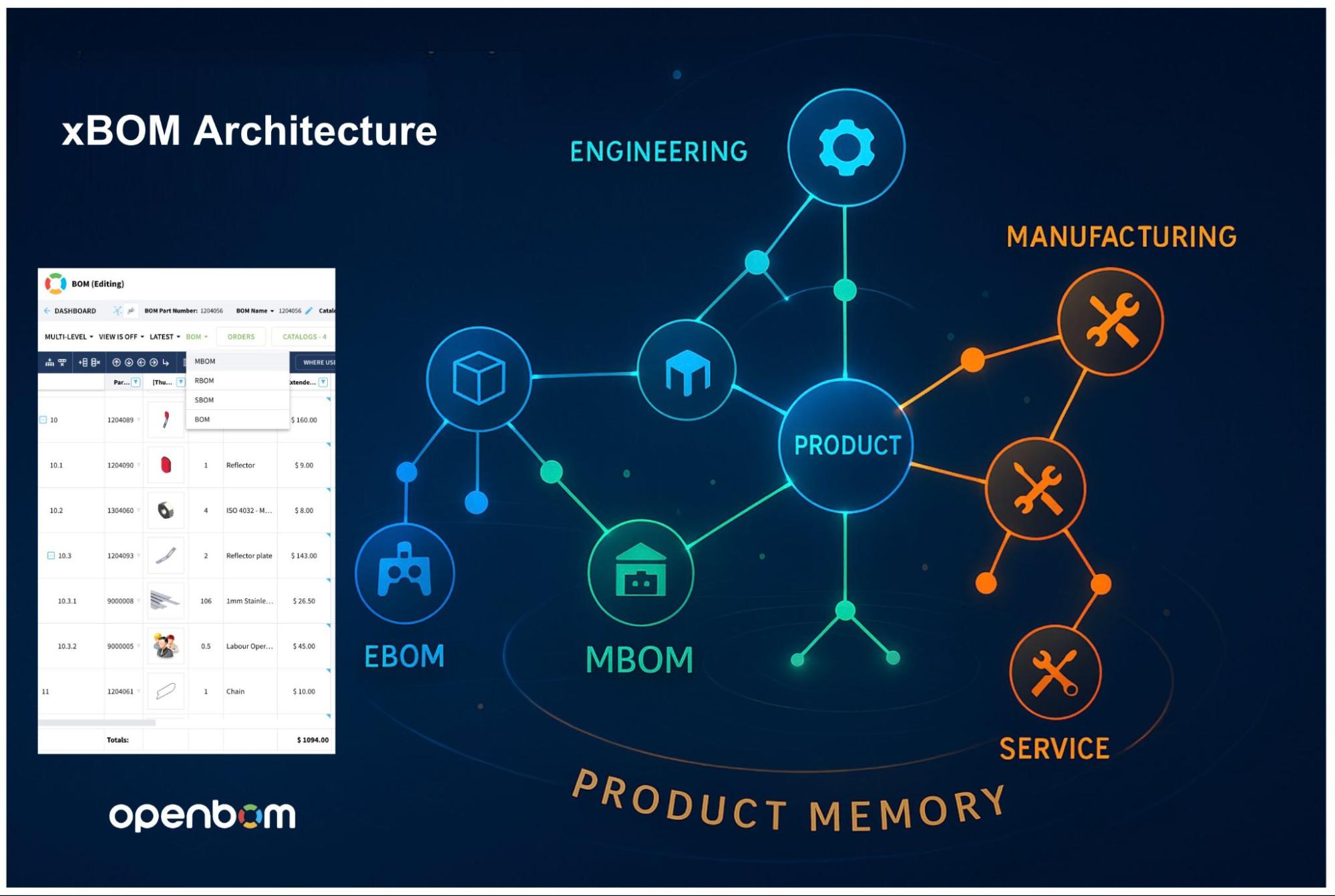

Now, we’re ready to explore one of the most powerful concepts shaping modern manufacturing data management — the xBOM. This is the core of OpenBOM – how to manage all structures and how to connect all pieces of product information – different BOM types. .

Every manufacturing company wrestles with the same question: How do we keep engineering, manufacturing, and service aligned on a single product definition? The question is absolutely needed to support the lifecycle and change management traceability.

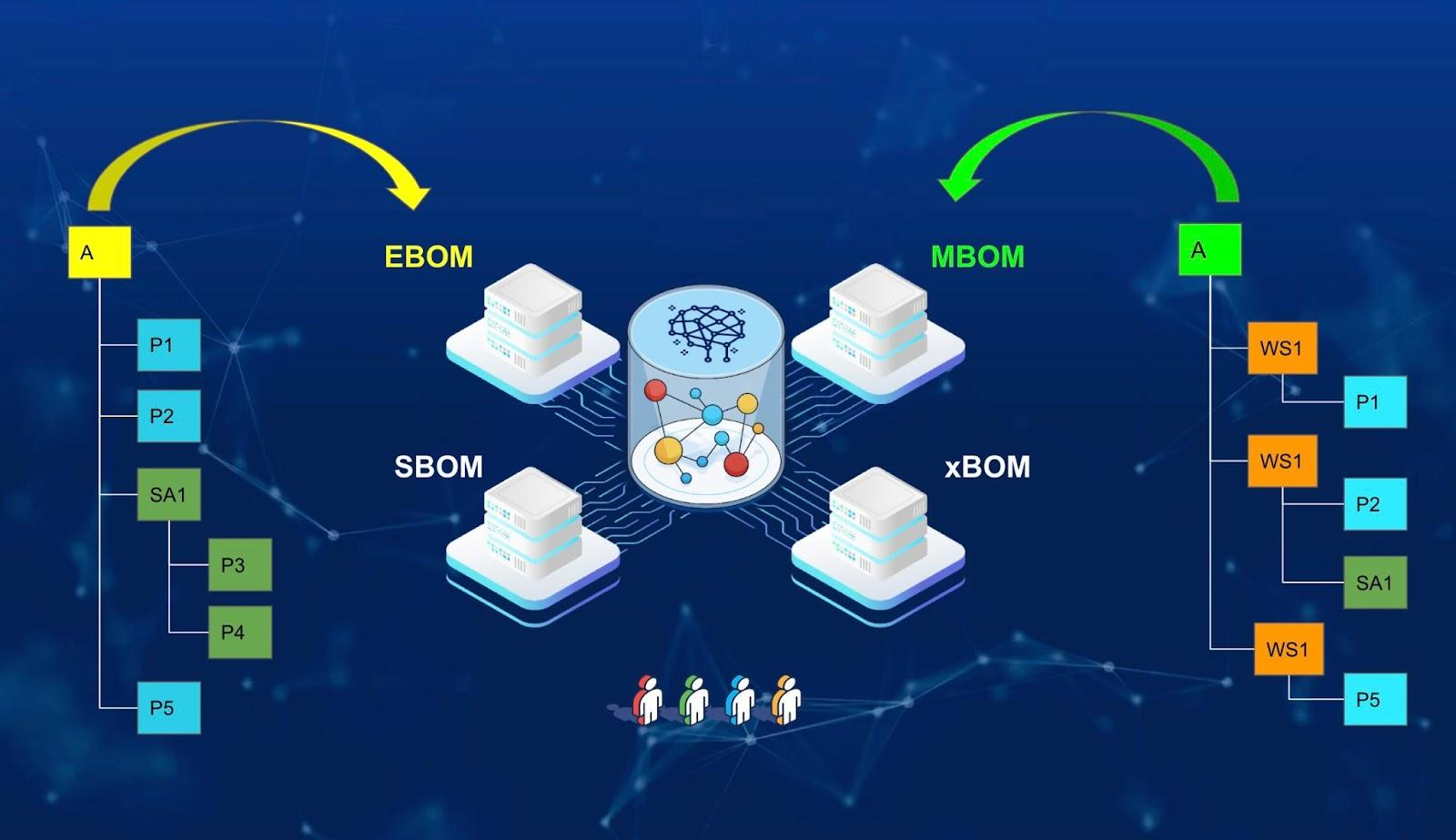

The answer is xBOM architecture — a graph-based, multi-view model that links every part, assembly, and lifecycle stage into one living structure. To sum up – One Graph, Many Perspectives. Let’s dig inside.

Why Collaboration Needs Structure

For decades, product data has been fragmented. Engineering manages EBOMs (Engineering Bills of Materials) inside CAD or PLM tools. Manufacturing has its own MBOMs (Manufacturing BOMs) in ERP or MRP systems. And Service operates yet another version — the SBOM, focused on spare parts and maintenance.

Each team has its own Excel sheets, file exports, and revision conventions. Every small change triggers a chain reaction of confusion, delays, and mismatches. In the case of multiple systems, it brings usage of multiple databases and import/export between them.

This fragmentation creates data silos, making collaboration reactive and error-prone.

OpenBOM’s answer to this long-standing problem is not another export/import pipeline — but a shared data model that treats every BOM as a different perspective of the same connected graph.

What is xBOM Architecture?

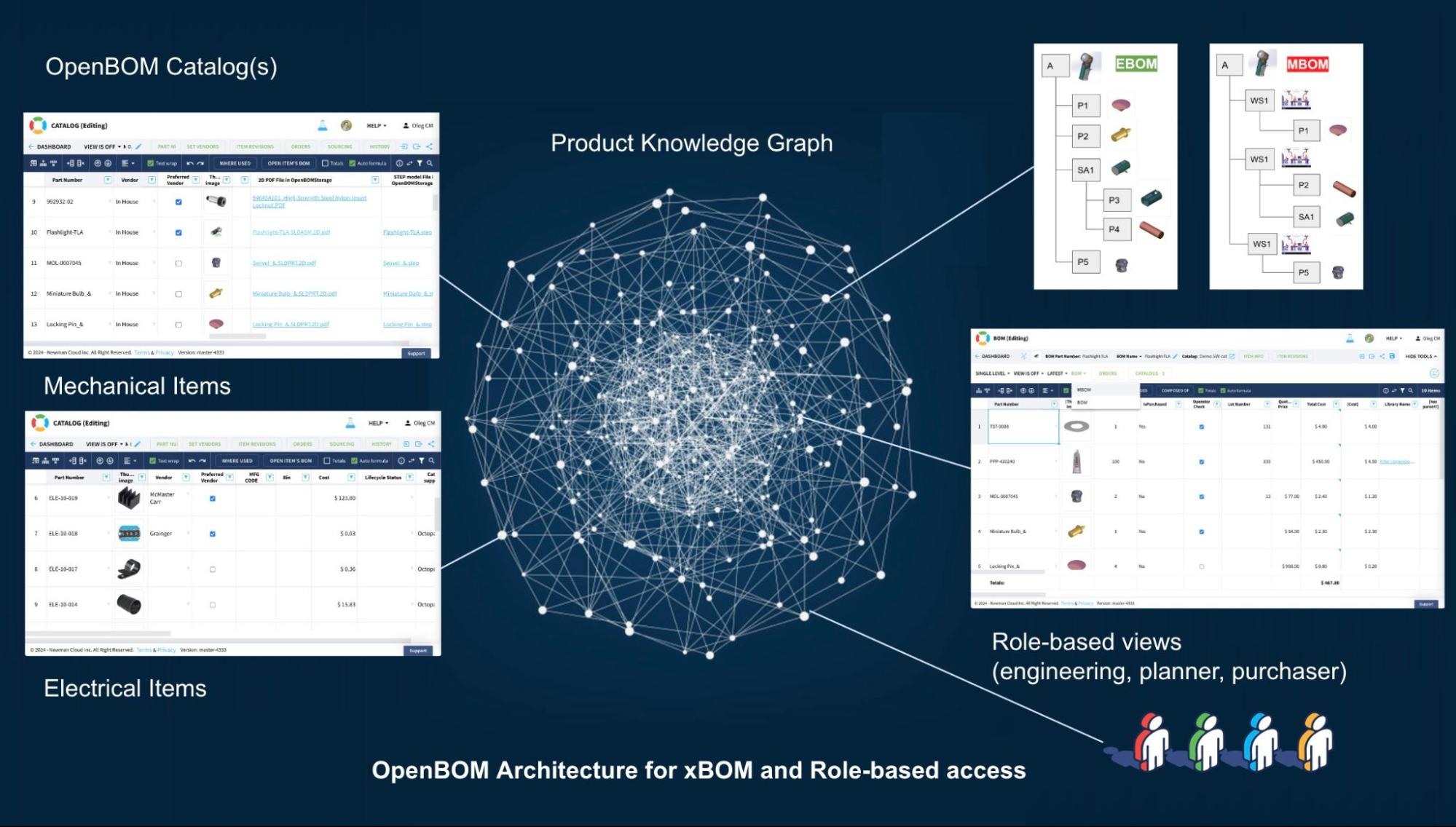

The xBOM (extended Bill of Materials) is the foundation of OpenBOM’s digital thread.

It represents a shift from document-centric to data-centric management — a world where product structures, revisions, CAD models, and suppliers all live as connected objects.

At the heart of this architecture lies OpenBOM’s graph-based product model, where:

- Every item, instance, relationship, and property is a node in a single product graph.

- Each node can be linked, reused, or extended across multiple structures — EBOM, MBOM, or SBOM.

- Views filter this graph dynamically, showing just what each role or process needs.

This allows engineering, operations, and service teams to share data without duplication or loss of context. EBOMs flow naturally into MBOMs; MBOMs evolve into SBOMs — all through the same reference-instance relationships.

How Teams See Their Own BOM View (Without Breaking the Model)

One of the biggest strengths of xBOM is multi-view collaboration. Each discipline gets its own structured perspective while staying connected to the same source of truth.

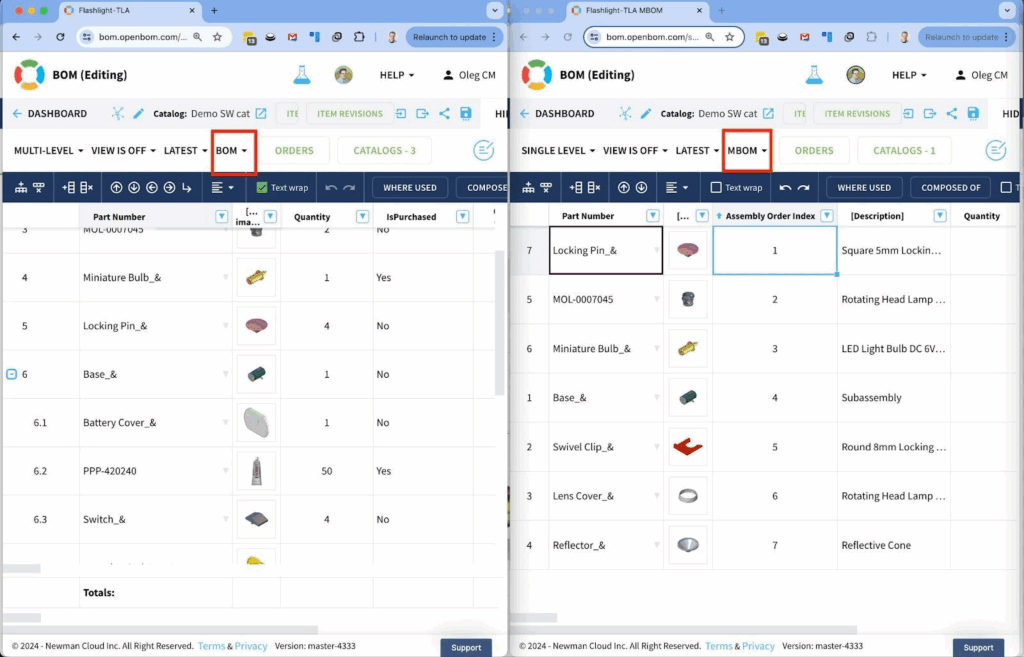

- Engineering View (EBOM) – Represents design intent. Parts and assemblies are defined by CAD metadata, parameters, and relationships. Every change in CAD is reflected in the digital structure.

- Manufacturing View (MBOM) – Adds operational context: manufacturing sequences, tooling, and vendor part numbers. It reflects how the product is built, not just what it is.

- Service View (SBOM) – Focuses on spare parts, maintenance kits, and configuration variants for post-production support.

OpenBOM custom BOM Types allows to organize as many product representations as needed, which gives a huge flexibility aspect in organization of product and manufacturing data.

What ties these together is the underlying graph — every change in one view propagates intelligently to others through shared references. Instead of isolated spreadsheets, teams collaborate through structured, real-time, role-based data.

How OpenBOM Transforms Traditional BOMs

Before xBOM, most companies used BOMs as static lists — simple tables describing assemblies and components. OpenBOM turns those static lists into living, digital product models.

Each BOM:

- Is directly linked to item catalogs, CAD data, and procurement sources.

- Can include derived attributes like weight, cost, or material consumption through formulas.

- Supports both single-level, multi-level, and flattened views for flexible navigation.

- Automatically updates when linked data changes — ensuring complete traceability.

OpenBOM’s approach merges the familiarity of spreadsheets with the structure of databases and the intelligence of graphs. It’s the best of all worlds.

The xBOM Advantage

The benefits of xBOM architecture extend across the entire lifecycle:

- Real-time sharing and traceability – One update is visible across all disciplines instantly.

- No duplication – Every component, property, and supplier exists only once in the data graph.

- Consistent structure – EBOMs, MBOMs, and SBOMs stay aligned automatically.

- Faster change propagation – Engineering changes flow seamlessly to manufacturing and service.

- Better decisions – Managers can analyze cost roll-ups, supplier performance, and design efficiency in one place.

As mentioned by many OpenBOM customers, xBOM gave us one system everyone could finally agree on. Engineers see what they need, buyers see their costs, and we never argue about which spreadsheet is right anymore.

What You Need to Support xBOM

Implementing xBOM isn’t just a technical task — it’s an organizational shift toward connected thinking.

To get started:

- Define your data model — identify key objects (items, vendors, orders) and their relationships.

- Align your processes — decide how EBOM, MBOM, and SBOM should relate.

- Establish roles and views — control visibility through permissions and filters.

- Use a graph-enabled, cloud-native system — like OpenBOM — to host and synchronize data.

- Adopt a culture of shared ownership — treat the BOM as a living product definition, not a deliverable.

When done right, xBOM becomes the backbone of digital collaboration.

From xBOM to Product Memory

Let’s add a bit more future flavor to this xBOM discussion. As we all try to figure out how AI will make its path into engineering and manufacturing, xBOM is a foundation for the future. xBOM doesn’t stop at defining today’s product — it builds the foundation of product memory.

Every revision, CAD link, manufacturing change, and service record becomes part of a continuous digital narrative. This data isn’t lost when a project ends; it accumulates into a knowledge graph — a living memory of how products are designed, built, and maintained.

Product memory extends xBOM’s reach from “What are we building?” to “What have we learned from everything we’ve built?”

It’s the natural evolution of PLM for the AI era — where insights from design, production, and field data fuel better engineering decisions and faster innovation.

In this way, xBOM evolves into something much greater – it is a persistent digital backbone that learns, remembers, and connects across generations of products.

Conclusion: xBOM as the Foundation of the Digital Thread and Product Memory

The digital thread begins with connection — and xBOM is that connection. It ties every engineering decision, manufacturing action, and service event to a single, traceable source of truth.

But more importantly, it remembers. As organizations adopt xBOM and build on it, they move from fragmented data management to continuous product intelligence — a state where every past iteration informs the next.

That’s the essence of OpenBOM’s vision to make product data open, connected, and alive.

REGISTER FOR FREE and check how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.