Welcome to Day 9 of my 30-day OpenBOM journey. So far, we’ve explored the foundation of OpenBOM’s architecture, collaboration, and digital thread philosophy.

Today, we move to the centerpiece of it all — the Bill of Materials (BOM) — and how OpenBOM redefines it for the modern, connected enterprise.

If you’ve ever built products, you know that managing a BOM can be both essential and painful. Spreadsheets break, version mismatches creep in, and design updates never seem to reach procurement in time. That’s because traditional BOMs were born in a world of documents — not data.

OpenBOM changes that. It transforms the static, disconnected BOM into a living, calculated digital model — one that evolves with every change, connects every stakeholder, and captures intelligence across the entire product lifecycle.

The Digital BOM and Reference–Instance Model – A Centerpiece of Product Knowledge

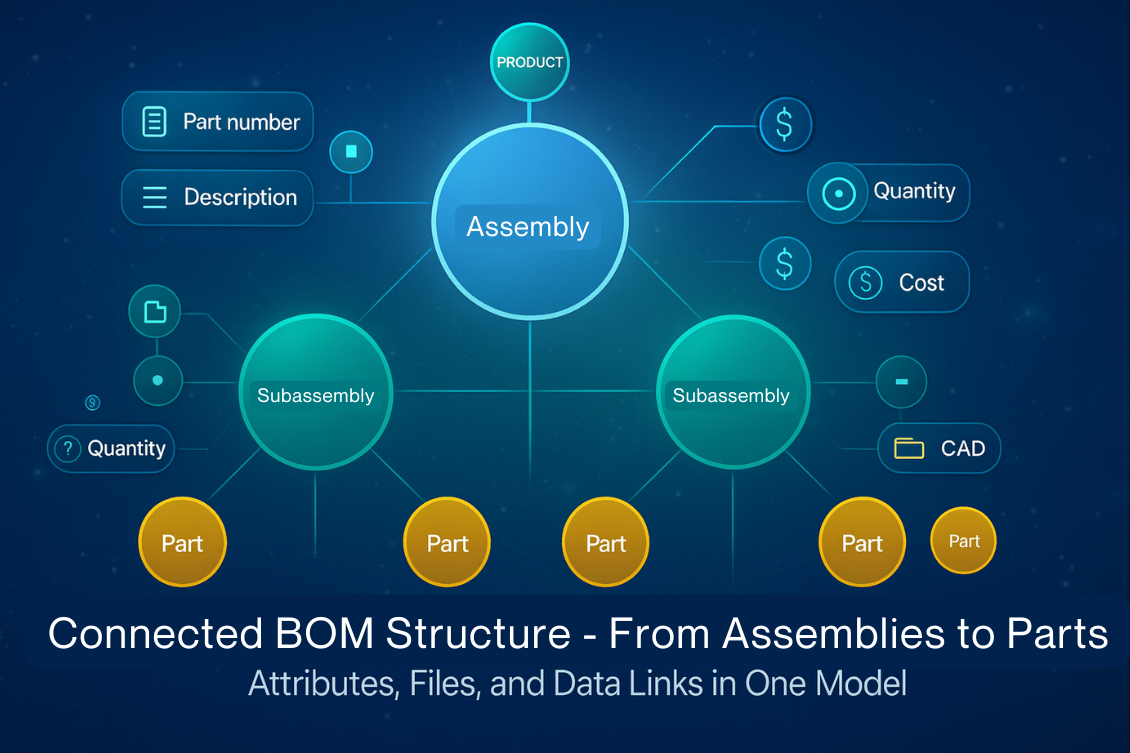

At its core, a Bill of Materials defines what a product is. But in OpenBOM, the BOM does more than list components — it becomes a structured, data-rich model of how parts, assemblies, suppliers, and costs all relate.

The core element of the BOM model is OpenBOM’s Reference–Instance Model, a foundational concept that enables both reusability and context awareness across every BOM.

- References (Items or Catalog Records): These are master definitions of parts or assemblies. They store persistent attributes such as part number, description, material, cost, and supplier.

- Instances: These represent each specific occurrence of a part within a BOM — including unique data like quantity, configuration, position, or reference designator attributes.

This distinction allows the same part to exist in multiple BOMs — say, a motor used in two different robots — without duplicating its definition. Each instance inherits common reference data but can carry unique, contextual details relevant to where and how it’s used.

This Reference–Instance Model forms the foundation of OpenBOM’s power. It’s what enables users to track relationships, calculate totals, and analyze performance across the entire product line — all while keeping data consistent and reusable.

In traditional spreadsheets or PDM tools, this kind of relationship management requires endless copying and manual updates. In OpenBOM, it’s automatic, scalable, and traceable — the digital backbone for modern manufacturing data.

Configurable and Flexible by Design

Every company has a different way to model its products — and OpenBOM was built to reflect that.

Rather than forcing users into rigid templates, OpenBOM’s flexible data model adapts to any product type or workflow. You can define custom properties, link items to CAD models or documents, and extend relationships to other systems.

A mechanical engineer may use OpenBOM to manage materials, part numbers, and machining tolerances. An electronics team might capture PCB layouts, firmware versions, and resistor values. A robotics manufacturer could mix both, connecting mechanical assemblies, electrical systems, and embedded software into a unified digital structure.

Because OpenBOM’s schema is user-configurable, each organization can model its data in the way that makes the most sense — all without IT customization or complex deployments.

Real-Time Collaboration and Change Capture

The next piece of the puzzle is collaboration, and OpenBOM was designed from the ground up to make it seamless.

OpenBOM’s Collaborative Workspace enables multiple users to co-edit BOM data in real time. Think of it as Google Sheets with PLM-grade discipline: structured, traceable, and secure.

When a design engineer changes a material or quantity, the cost engineer sees updated totals instantly. The buyer sees the procurement impact. The supplier sees updated requirements.

Everyone works on the same version of truth, at the same time.

All changes are automatically tracked, versioned, and stored — creating a transparent history of who changed what, when, and why.

This real-time collaboration eliminates the friction of file checkouts, exports, or email threads. The BOM simply becomes a shared workspace — live, connected, and continuously accurate.

OpenBOM BOM Types – Navigating Structures Your Way

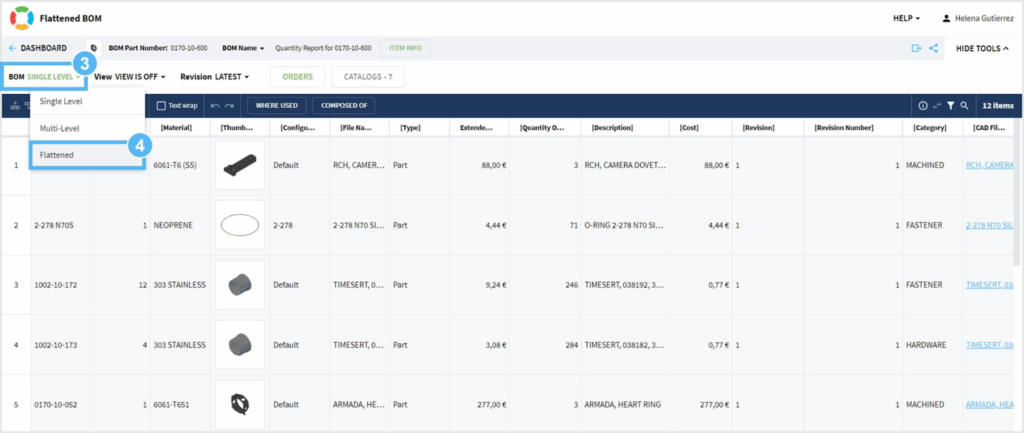

Different users need to view the same data in different ways — and OpenBOM provides multiple built-in BOM types to make that navigation intuitive:

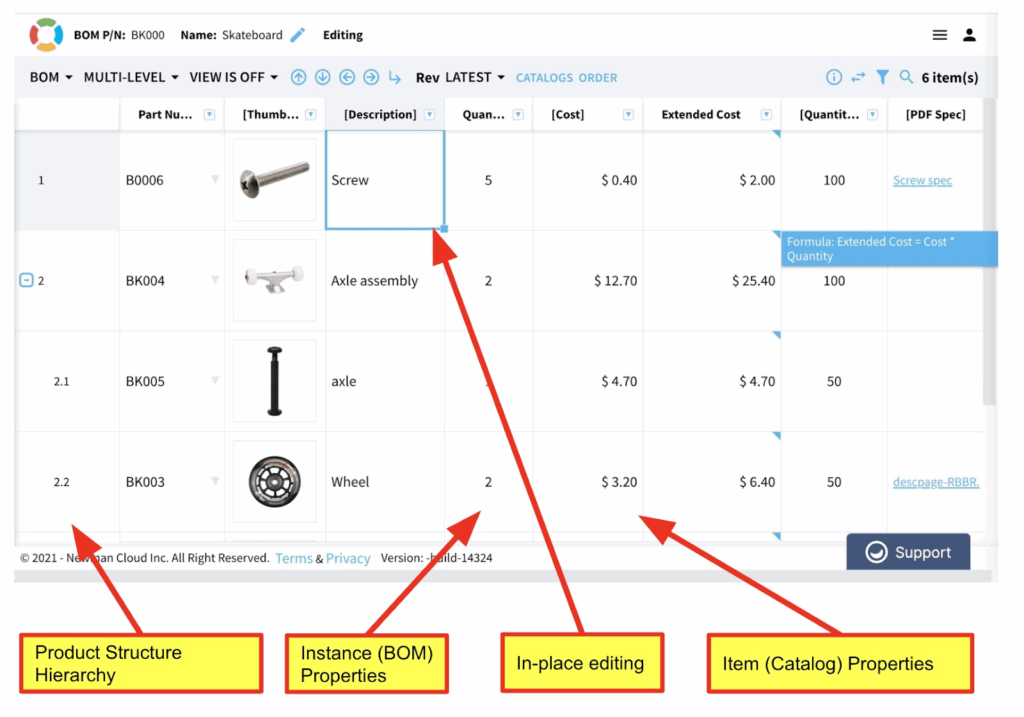

- Single-Level BOM – Focus on one assembly level at a time. Perfect for detailed design edits, property updates, and subassembly reviews.

- Multi-Level BOM – Expand the full hierarchy of assemblies and subassemblies in one view. Ideal for system-level analysis, configuration, and roll-ups.

- Flattened BOM – Consolidate every part and quantity from all levels into one aggregated table. Great for procurement, inventory checks, and cost estimations.

These views are dynamic and fully synchronized — meaning changes made in one view reflect everywhere else instantly. Engineers, planners, and buyers can each navigate the same structure in the way that best fits their workflow — without breaking the data model.

Formulas and Roll-Ups – Intelligence Built In

Once the data is structured, OpenBOM turns it into a living analytical model through built-in formulas and roll-ups.

With OpenBOM’s formula engine, users can perform calculations directly within the BOM, linking fields across levels and assemblies. You can compute total costs, accumulated weights, lead times, and even environmental metrics — all without leaving the workspace.

Examples:

- Cost Roll-Up: Automatically aggregate part and assembly costs from catalog data and supplier pricing.

- Weight Roll-Up: Calculate total product mass for logistics, compliance, or sustainability.

- Quantity Validation: Automatically compare expected versus actual quantities to catch errors before production.

Because formulas are tied to the live data model, updates occur automatically whenever inputs change. This makes the BOM a real-time analytical engine, not a static record.

Views, Roles, and Insights

Not every user needs to see everything. OpenBOM’s user-defined Views let teams focus on the data that matters most to their role.

A design engineer can view CAD properties, materials, and geometry. A buyer can see costs, vendors, and lead times. A manager can view only roll-ups, statuses, and release dates.

Each view acts as a lens into the same underlying data. Administrators can restrict access at the object or property level, maintaining control and security while still allowing open collaboration across teams and partners.

This system creates a balanced model of openness with governance — one that encourages transparency without compromising intellectual property.

The Complete Product Record – More Than a BOM

In OpenBOM, a BOM isn’t an isolated document — it’s part of a comprehensive product memory.

Each BOM is connected to its items, catalogs, CAD models, documents, and revisions. Together, they form a digital thread — a network of data that captures every relationship and evolution of the product.

Attachments, CAD drawings, images, and change orders can all be linked to specific items or instances, preserving context for design, manufacturing, and maintenance teams. Every change is traceable, every revision accessible.

This completeness is what allows OpenBOM to serve as a single source of truth — not only for engineers, but for procurement, quality, and production as well.

Closing Thoughts – The Living BOM as a Foundation for Intelligence

In most organizations, the Bill of Materials is where information goes to die — locked inside spreadsheets, disconnected from CAD, and invisible to the business.

In OpenBOM, the BOM is reborn as a living, intelligent model — connected to everything, updated in real time, and shared seamlessly across functions. It’s the foundation of digital collaboration, process automation, and even AI-assisted decision-making.

The Reference–Instance Model ensures every piece of data — from item to usage context — is traceable and reusable. The formula engine makes analytics part of the workflow. The collaboration layer ensures everyone is working from one shared truth.

This is how OpenBOM replaces the friction of spreadsheets with the fluidity of connected data. It’s not just a better way to manage BOMs — it’s a new way to think about product data altogether.

🔜 Next up: Day 10 – Design Projects and PDM service

We’ll explore how the same model that powers OpenBOM’s flexible BOMs extends into Design Projects, enabling structured file management, PDM capabilities, and change control across CAD environments.

Meantime REGISTER FOR FREE and check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.