Welcome back to Day 10 of the 30-Day OpenBOM Learning Journey!

In Week 1, we covered the “why” behind OpenBOM — the philosophy, architecture, and the digital thread mindset.

In Week 2, we’re diving into the “how” — exploring the key features that make OpenBOM a modern, connected workspace for product development.

Over the last couple of posts, we introduced OpenBOM’s data model, collaboration foundation, and the concept of a digital BOM. Today, we’re taking the next important step: understanding how OpenBOM manages design files and connects them into the full product lifecycle.

If the BOM is the heart of product data, then Design Projects are the bridge that brings CAD design into the digital thread, enabling controlled, collaborative, cloud-based design data management — without the overhead of legacy PDM systems.

From File Vaults to Connected Design

For decades, Product Data Management (PDM) revolved around one core objective: store CAD files and control who changes them.

Traditional PDM solutions were built as:

- Local file vaults

- Configured for on-premise servers

- Accessible only via VPN

- Focused solely on engineering teams

These tools did their job well for the era they were built for — a time when engineering was isolated, products were mechanical, and collaboration happened within a single building.

But today’s world is different.

- Products now span mechanical, electrical, and software disciplines

- Teams are distributed and work across time zones

- Supply chains are global

- Engineering, manufacturing, procurement, and contractors need shared access

- Designs must flow to BOMs, orders, manufacturing, and service — not just sit in a vault

Legacy PDM stores files.Modern PDM must connect data. This is the gap OpenBOM was designed to solve.

OpenBOM takes a fundamentally different, cloud-native approach: instead of isolating CAD in a vault, it integrates CAD data into the full product lifecycle, enabling traceability from design to manufacturing to procurement.

What Are Design Projects?

Design Projects are OpenBOM’s collaborative PDM layer — the place where design files, revisions, and engineering context come together.

Think of a Design Project as more than a folder of CAD files. It is a living workspace that understands relationships between files, items, BOMs, and change processes.

Each Design Project organizes and connects:

- CAD files (assemblies, parts, drawings)

- CAD file versions with full version history

- Links to Items, BOMs, and the revision process including ECO and change management

This means that your CAD models don’t live in isolation — they are linked to product Items, to BOMs, to revisions, and to your business decisions.

A design change isn’t “just a new file” — it becomes part of the digital product model.

Because Design Projects are cloud-native and multi-tenant, they are instantly accessible to engineers, manufacturing, contractors, and even suppliers — with the right permissions — no VPN, no server installation, no IT burden.

You get the control and discipline that engineers expect from PDM, without the heavy infrastructure or complexity.

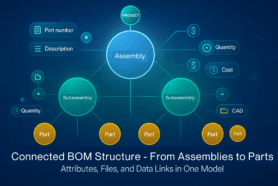

OpenBOM’s Flexible Graph-Based Data Model

Everything in OpenBOM is connected through a graph-based data model that links product information as relationships, not isolated files or spreadsheets.

Design Projects use the same model that powers BOMs, catalogs, suppliers, orders, and more — enabling a connected product lifecycle.

OpenBOM’s graph model connects:

- CAD file versions

- Items (master records)

- BOM revisions (structure over time)

- Suppliers, orders, vendors

- Projects, documentation, and more

This creates a single, contextual network of product knowledge instead of siloed file storage.

Why this matters

- CAD design changes stay connected to version history — each file version is stored, tracked, and linked

- CAD versions aggregate into Items and BOMs, ensuring that your BOM always reflects the correct design

- Multi-disciplinary design is supported (mechanical, electrical, software)

- End-to-end traceability and analytics become possible across engineering, BOM, procurement, and manufacturing

This model transforms OpenBOM from a file repository into a connected, contextual digital product memory — the foundation required for automation, workflows, and AI-assisted engineering.

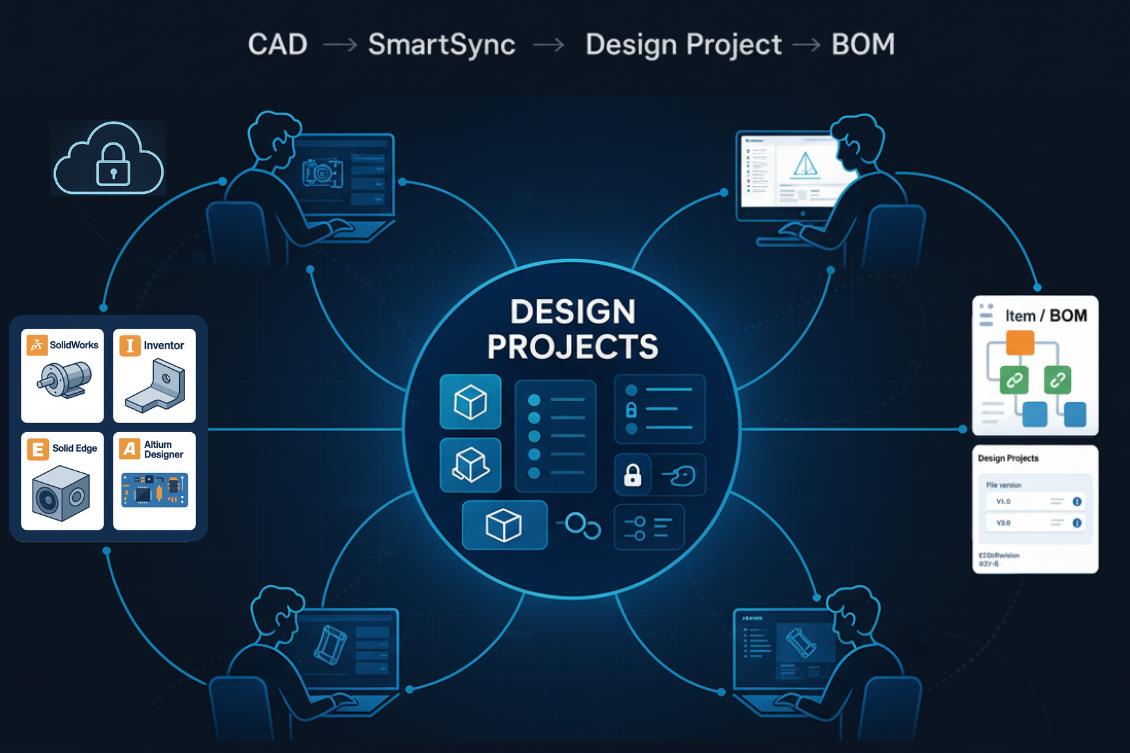

SmartSync – CAD-to-Cloud Made Simple

One of the biggest challenges with moving engineering into the cloud is:

How do you bridge desktop CAD with a cloud system without disrupting how engineers work?

That’s where SmartSync comes in.

SmartSync is the secure, intelligent connection between desktop CAD and OpenBOM’s cloud data model. It allows engineers to work on their local machines as usual, while ensuring data stays connected, synchronized, and traceable.

SmartSync enables teams to:

- Upload CAD files and full assembly structure securely — without exporting manually

- Use collaborative lock mechanisms for check-in/check-out, controlling file edits across distributed teams

- Maintain full version history and metadata links, preserving design intent

- Automatically connect design objects to Items, BOMs, and catalogs, keeping product data synchronized

- Generate, store, and manage derivative files (STEP, PDF, DXF, STL, etc.) for manufacturing, collaboration, and releases

SmartSync removes friction between local CAD work and cloud collaboration. No shared drives. No “who has the latest file?” doubt. No VPN or IT maintenance.

It’s PDM — modernized.

Collaborative Design Workspace

Design Projects introduce something legacy PDM tools never achieved well: true collaborative engineering.

OpenBOM’s collaborative workspace allows multiple team members to work together without creating conflicts or duplications.

With collaborative design:

- Multiple users can work in the project at once

- Distributed check-in/out keeps the process safe and controlled

- No overwriting, no lost files, no version chaos

- All changes propagate through the data model automatically

Imagine a mechanical engineer updating a part while a manufacturing engineer reviews the related BOM — and both see updates instantly.

It feels like “Google Docs for engineering data” — but with the rigor, structure, and traceability engineers require.

Revision Control and Change Management

A design is only as good as its traceability.

Design Projects include:

- Full revision and version history

- Structured release and approval process

- Integrated ECO workflows (Engineering Change Orders)

- BOM-to-design revision linking

- Traceability from design → release → manufacturing

This means when a part changes:

You know who changed what, when, and why — and how it impacted cost, sourcing, or production.

Change is no longer chaotic — it becomes managed knowledge.

CAD Integrations in Action

This is where the picture comes together.

OpenBOM’s CAD integrations allow teams to work in any CAD environment — desktop or cloud — and still stay connected to the same product model.

OpenBOM provides deep integrations with desktop CAD systems such as:

- SolidWorks

- Autodesk Inventor

- Solid Edge

- Altium Designer

- Other desktop CAD systems

These add-ins synchronize CAD data directly with OpenBOM, ensuring data stays accurate, contextual, and up-to-date.

At the same time, OpenBOM integrates natively with cloud CAD platforms including:

- Onshape

- Autodesk Fusion

- Altium 365

This allows for instant cloud-to-cloud synchronization with no manual steps.

Why this matters

Teams often run mixed-CAD environments. Mechanical engineers may use SolidWorks; electronics may use Altium; industrial design may be in Fusion.

Historically, this created data silos.

With Design Projects:

- Desktop CAD remains fully supported through SmartSync

- Cloud CAD connects instantly to the shared product model

- Teams can collaborate across tools, disciplines, and locations

- The digital thread remains intact end-to-end

Example: A SolidWorks assembly check-in automatically updates the BOM, metadata, and linked components in OpenBOM — no exports, spreadsheets, or manual sync required.

This is a unified CAD-to-BOM workflow, built for modern product development.

Why It Matters: From Engineering Silos to Connected Product Development

Most companies today still operate like this:

- Engineering designs the product

- At the end, they “throw it over the wall” to manufacturing or purchasing

This creates delays, misalignment, and costly mistakes.

Design Projects change that. By connecting design data to BOMs, revisions, suppliers, and operations — as the work happens — OpenBOM creates:

- A single continuous digital thread

- Earlier collaboration between engineering → manufacturing → procurement

- Shared knowledge, not file hand-offs

- A foundation for automation, AI, and connected decision-making

This is how you eliminate rework, accelerate releases, and improve quality.

Conclusion: Design Projects and Digital Thread

Design Projects are more than cloud PDM. They represent a new way to think about design data in the context of the entire product lifecycle.

They unify:

- Design files and their versions

- Item and their Revisions

- Product structure (BOMs)

- Metadata

- Change process

- Procurement and manufacturing context

This creates product memory — a foundation where data doesn’t get lost between tools or departments, but becomes accumulated knowledge.

With this, OpenBOM moves PDM from “file control” to connected product development.

Tomorrow — in Day 11 — we’ll continue this theme and go deeper into CAD Integrations, exploring how OpenBOM keeps data flowing from design to BOM to procurement with no manual work. Stay tuned — this is where the digital thread gets exciting.

Meantime, REGISTER FOR FREE to check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.