Throughout the new product introduction (NPI) process you will be working with multiple different parties. One of the main parties you will continue working with well past launching your product is your contract manufacturing partner. Your contract manufacturer (CM) is an integral part of your organization and one that will be supporting you throughout the entire lifecycle of your product.

Streamline Information Flow Between OEM and Contract Manufacturer

Your relationship with the CM is very important. How do you streamline the way you share data? Do you use Spreadsheets? There is always a time and a place for spreadsheets. My team and I used spreadsheets as the main way to communicate with clients for years. Spreadsheets were how we managed the bill of materials (BOM) and since the BOM holds the data for manufacturing your product, spreadsheets became a tool for communication with our clients.

This was because whenever you made a change or a revision, there was an updated BOM. When you made a change in the price to reflect currency fluctuation, material prices, changes in the design, there was an updated BOM. If during DFM, you combine two parts to become one, there is an updated BOM… As you can see, BOMs get passed around a lot.

While Excel is a good and flexible tool it has many problems when it comes to BOM management. Read more about it here.

The downside of using Spreadsheets

So the question is, do you want to constantly pass around something that holds the data to your product, or do you want to automatically share it?

I am guessing you want to stop sending emails back and forth and stop worrying whether or not you updated the revision on the BOM or if you put the newest drawing with the correct part number in the correct folder on Google Drive…

The amount of risks associated with using spreadsheets is quite high. Just think of not being able to update a part in the BOM that had a change in the part database, or a very simple copy and paste error. Or, what we have seen before is deleting data and having to go back through countless spreadsheets to recapture the lost data.

However, the most fundamental thing about spreadsheets is that they are not meant to manage and store your manufacturing data. But perhaps out of convenience, we have used it to transfer data to your CM partner for years.

Here are some other downsides of using spreadsheets:

- Limited sharing capabilities

- Unable to capture historical data

- Not a centralized system

- No integrations with CAD or other software you might find necessary.

Is it time to change the way you share data with your CM?

A change in habit is always difficult. There are also costs associated with switching to another system. However, the risks associated with staying with spreadsheets far outweigh the costs of changing to another system.

Before you proceed with changing the way you share data with your CM, consider the following questions:

- Do you use the same part or item for multiple different products?

- Is your BOM changing, growing, and evolving?

- Has managing spreadsheets become a part of your job?

- Do you need to manually save each BOM and send it out after every minor change?

- Do you have a change management system set up in spreadsheets?

Depending on the answers you provide, you might find it useful to search for options to get you out of the spreadsheet madness.

How can OpenBOM help?

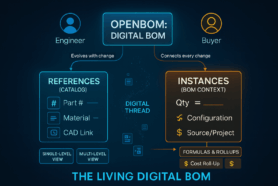

OpenBOM believes engineering, supply chain, and manufacturing teams should be able to seamlessly manage their parts, vendors, bill of materials, purchase orders, and change orders. All BOM, engineering, and manufacturing information are stored in the cloud which you can share with your team, contractors, suppliers, or anyone else that has access to your account. OpenBOM keeps everyone on the same BOM while providing you with the tools to streamline your development to production & scale up operations.

Register for FREE to create your OpenBOM account and reach out to us via support @ openbom dot com if you have any questions.

Best,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.