What is the Bill of Materials? The question is simple, but the answer is not. Asking this question in your team, you can find a diversity of answers and for a big surprise, you find all of these answers correct.

Two main groups of people focusing on BOM and materials are engineers and project management. For engineers, the Bill of Materials is about the structure of components, quantity, and cost. The focus is on how not to forget something to be included in the BOM. Collaboration between team members and the automatic extraction of data is paramount. For project managers, BOM is also important. However, the focus on project management is about purchasing, scheduling, and validation. As you can see both groups of users live from the same data, but paying attention to different aspects. Other groups of users such as procurement, contractors, suppliers are also looking at BOM, but focusing on specific segments of information.

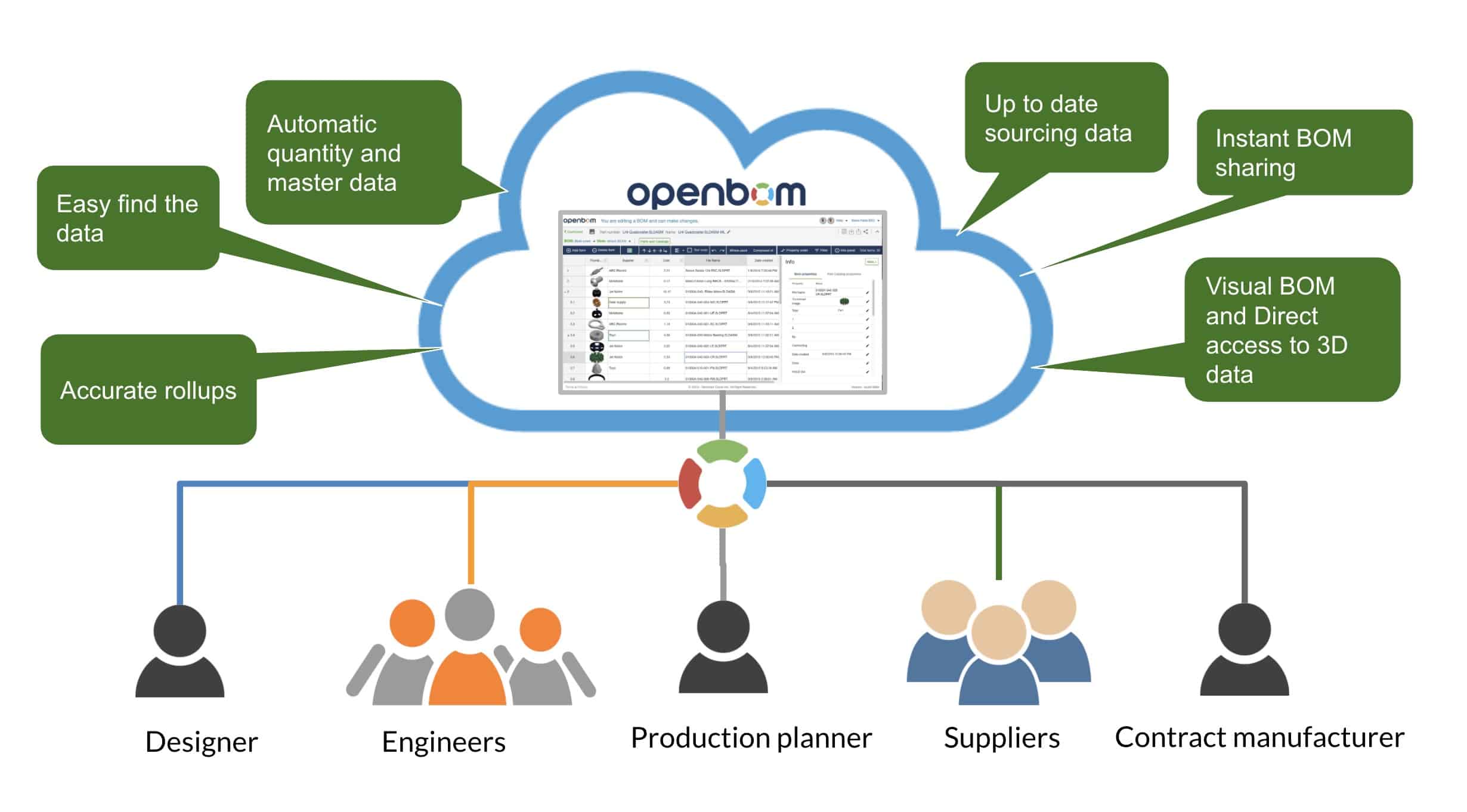

At OpenBOM, we focus on how to bring everyone on the same BOM. After helping thousands of users and companies, we’ve learned that finding a common language between all these users is key to solve the problem. OpenBOM data management flexibility is a foundation to provide a solution.

Usually, different BOM consumers are focusing on finding the right “template” to create a BOM in Excel and maintain the data. Holding the data in Excel gives them a false sense of insurance of data consistency and completeness. In fact, creating data in Excel templates is a major factor to create data silos and make mistakes. Copy data between Excels is just icing on the cake of BOM in Excel data mess.

So, what are the best practices to follow to stay away from the BOM Excel mess? Here are some recommendations you can easily achieve by starting to use OpenBOM today.

1- Don’t use a spreadsheet to manage BOM.

Bill of Materials is a complex data structure including components, assemblies, and their usages. Excel cannot provide you a reliable data management capabilities and you will be copy data between multiple BOMs and losing a single version of the truth. You end up with multiple records for the same parts and inconsistent data. The cost rollup is impossible in Excel and data sharing turns out into Emails with Excel attachments, which ends up with the wrong Excel and wrong data. Import data to OpenBOM is easy using Excel import or CAD integrations and you will stop looking for these Excels anymore.

2- Automatic updates and instant data sharing (a-la Google Sheet).

Each time you copy data, you have a potential mistake and it ends up very bad. Wrong quantities, part numbers, cost, and lead time – this is only a shortlist of possible mistakes. Stop relying on manual data extraction and updates. OpenBOM CAD integrations and Excel import can merge changes from the outside to OpenBOM and update only the information you need while preserving changes that were made to product data in OpenBOM.

OpenBOM instant data sharing and simultaneous editing allows members of your team to access data at the same time, makes editing easier and to provide a visual indication for users collaborating on the same BOM. Everyone is familiar with Google-like “share” functionality and this is exactly what OepnBOM does, but for Bill of Materials.

3- Role-based BOM access with Team Views

Everyone needs to have the right data to be available to the right people at the right time. It is a very simple formula, but it is very hard to make it happen when your data is siloed, copied between CAD, Excel, Emails, and spread between multiple people.

OpenBOM can clean this mess for you managing a single version of truth (catalogs and BOMs), sharing it instantly for the right people, and applying role-based user-defined views, so people will only see what they need.

Conclusion

Stop looking for BOM Excel Templates. If you think you can secure the data you need in a special template and then send it to the right people, you’re making a huge data management mistake, that will cost you a lot of money via wrong quantities, wrong versions of the bill of materials, mistakes made because of manual updates and exposing sensitive data to the people that don’t need to see it.

Check our how OpenBOM helps thousands of users and manufacturing companies to manage data. You can be part of them. The best practices I outlined can be implemented using OpenBOM professional and team subscription. Just by thinking about your last BOM mistake, you can realize the ROI of the solution is fantastic and can be accomplished very quickly using OpenBOM risk-free monthly subscriptions.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.