Talking to many companies, it’s not unusual to hear a familiar refrain: “We don’t have time to solve data management. We’re using a temporary solution for now. When we have more time and things get more complex, we’ll deal with it.”

I found most companies (and not only companies) are afraid of transformations. As humans, we are afraid of changes. Even though those changes are coming to help improve what we do, we are afraid and we see a lot of risks in the transformation process.

But here’s the problem: You’re missing the main point of a digital world—data is now a fundamental part of your business. In the past, “documents” were part of the working process and the outcome—drawings are a prime example. Today, data is the core element of every digital business. It’s something that can either make or break your business.

Why is Transformation Needed?

In the ever-evolving landscape of manufacturing and product development, transformation is no longer an option—it’s a necessity. Here’s why:

Growing Complexity: As products become more sophisticated, the complexity of managing their development and production increases exponentially. Traditional methods struggle to keep up, resulting in inefficiencies and errors.

Digital World: The shift to a digital-first approach in every industry demands a robust data management system. Companies need to harness the power of digital tools to remain competitive and agile.

Connecting People, Teams, and Organizations: Effective collaboration is crucial for success. Seamless communication and data sharing across different teams and organizations ensure that everyone is on the same page, reducing the risk of miscommunication and mistakes.

In my article today, I will focus on 5 elements of transformation OpenBOM brings to engineering teams and manufacturing.

1. Put Data at the Center of Your Product Development

The key to successful product development lies in the efficient management and utilization of data. The old world was about creating documents (eg. Drawings) and sending them to manufacturing, whose role is to order parts and assemble them. OpenBOM’s approach centers around a digital model that transforms product development:

Growing complexity makes companies face urgent and significant problems in managing their product data. Every team I’m working with is looking for a better way to manage These companies understand the critical importance of accurate and accessible information for their product development processes.

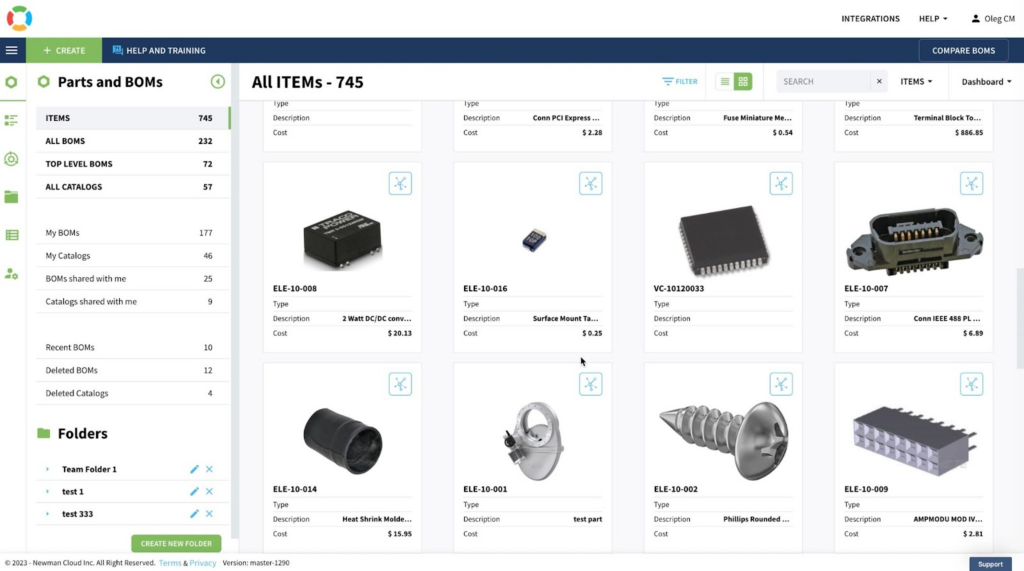

To solve the problem of complexity, OpenBOM offers an online, flexible, and integrated product information model. This model encompasses every aspect of the product you’re building, ensuring that all data is organized, connected, and easily navigable.

OpenBOM offers a different engagement model and solution delivery approach, which is an online SaaS. The product service is available instantly, everyone can register and start exploring and trying to use it right away – from instant try to online purchase and onboarding.

2. Data: Product Knowledge Graph Core and Simple User Experience

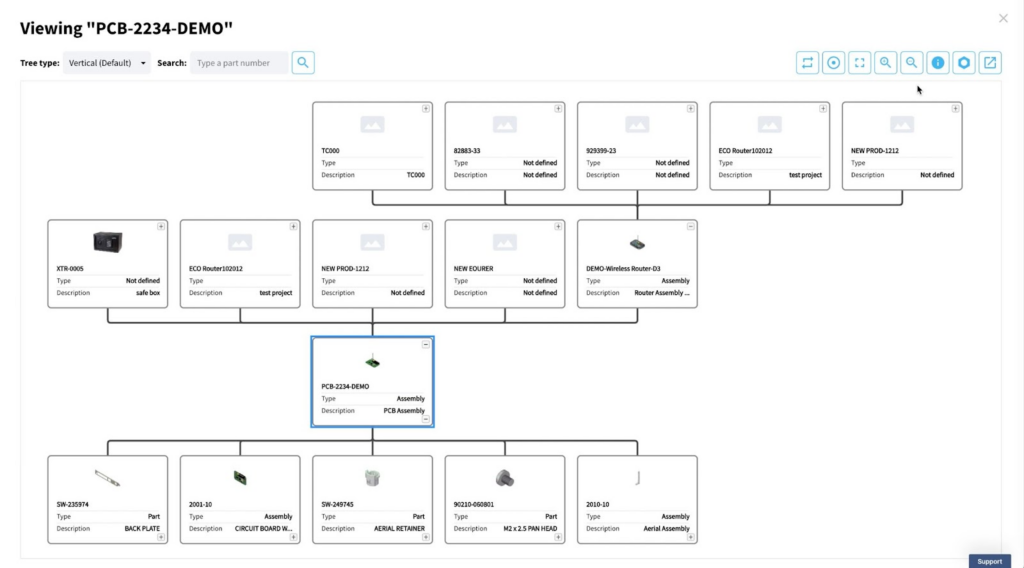

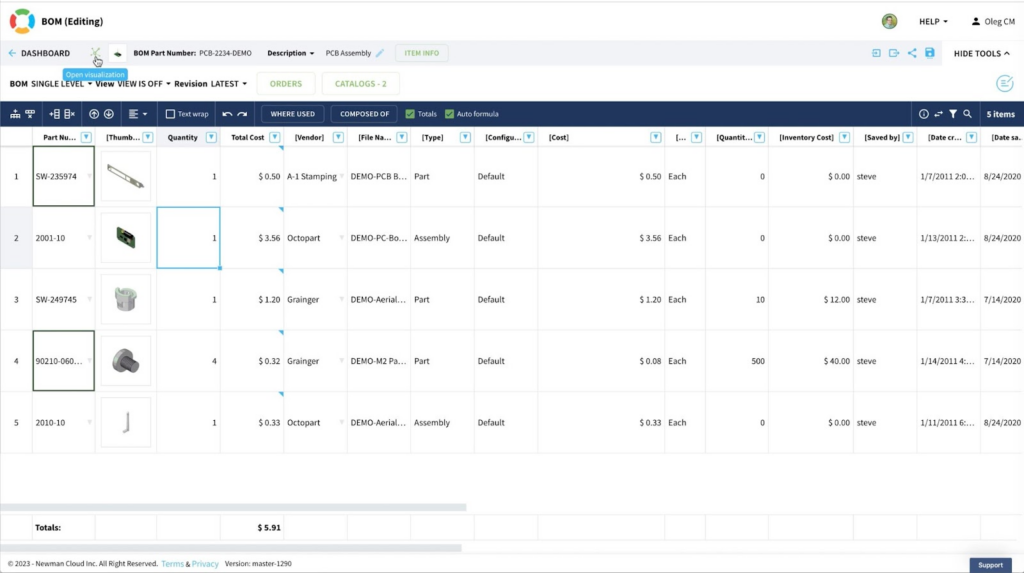

OpenBOM’s core technology is a flexible and simple online product knowledge graph. This system organizes all product data, making it interconnected and easy to access. With this approach, navigating through the product’s history and dependencies becomes straightforward, significantly enhancing the efficiency of product development.

At the same time, OpenBOM offers a user friendly interface and navigation paradigm, which is a combination of “spreadsheet-like” data object visualization combined with graph navigation and integrated user interface in design and other enterprise applications.

Visual Dashboard

Graph Navigation and Queries

Simple Spreadsheet Like Editor

3. No Hands: Capturing Data Automatically from Multiple Data Sources

One of the standout features of OpenBOM is its ability to capture data automatically from various sources. Whether it’s generating derivatives, calculating costs, or compiling data from different systems, OpenBOM does it all seamlessly. This automation reduces manual entry errors, saves time, and ensures that all data is up-to-date and accurate.

4. Manager’s View: Visibility into Team Activities and Product Status

Managers gain comprehensive visibility into their teams’ activities and the overall product status with OpenBOM. This enhanced oversight enables better decision-making, as managers can see how different parts of the product are progressing and identify any potential issues early. This visibility leads to more efficient project management and a clearer understanding of the product’s lifecycle.

5. Business Benefits: ROI, Eliminating Mistakes, Saving Costs, and Speeding Up Work

By integrating OpenBOM into their product development processes, companies can achieve significant business benefits:

Make More Money: With streamlined processes and better data management, companies can bring products to market faster and more efficiently, increasing revenue potential.

Save Money: Eliminating manual data entry and reducing errors leads to cost savings, as does the more efficient use of resources.

Mitigate Risks: Better data management helps identify and address risks early, reducing the likelihood of costly mistakes and delays.

Keep in mind, one simple mistake found using OpenBOM can cover the subscription cost. Read the story of VarTech – “I remember we caught a $1000 mistake the first month we had OpenBOM. Our Excel had not been updated. OpenBOM literally paid for itself that month.”

What Are Business Risks of Keeping The Status Quo?

Sticking to the status quo comes with its own set of risks:

Slow Delivery: Without efficient data management, product development processes can be slow and cumbersome.

Lack of Access to Dependencies: Ineffective data management means not having access to all product dependencies, leading to incomplete or flawed products.

Poor Collaboration: Bad collaboration results in mistakes, rework, and inefficiencies, ultimately affecting the product’s quality and market success.

Conclusion:

Many customers have successfully transformed their product development processes with OpenBOM. These companies have improved their data management, reduced costs, and enhanced product quality. Failing to focus on data management means staying behind the competition, facing higher costs, and dealing with low-quality products.

OpenBOM empowers companies to stay ahead by providing a robust, cloud-native PDM & PLM platform that enhances every aspect of product development. Embrace the transformation, put data at the center, and see the difference it makes.

REGISTER FOR FREE and check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.