In the ever-evolving technology landscape, hard tech companies find themselves grappling with increasing competition. The complexity of building hardware is unprecedented these days. Every product in high-tech, medical, biotech, industrial automation, and consumer products is a complex piece of equipment including mechanical, electronics, embedded software, connected cloud technologies, and more. How to build such products without losing track of competitors, controlling cost and supply chain? You need to have a different level of tools. Different from what manufacturing companies used before. Modern manufacturing companies are looking at how to operate in an efficient way, balancing their engineering, manufacturing, and supply chain management capabilities.

Hard Tech Operational Challenges

Hardware business is extremely complex and competitive with numerous companies vying for market share. To remain relevant and ahead of the curve companies need to lean into their unique value proposition and streamline their design and operational processes. Hard tech companies grapple with high customer demands, coupled with rising costs and unpredictable supply chain fluctuations. In this volatile environment, informed decisions backed by comprehensive data can be a game-changer. It all comes to the understanding of the products and process, which ultimately leads to the understanding of data. This is where a shift in focus from mere applications to data is imperative.

Building Faster and Efficiently

In the race to launch products, efficiency is paramount. Access to consolidated, reliable data ensures that companies can deliver products on time, with predictable costs, thus effectively countering supply chain challenges.

The key element in accelerating the production process and efficiency is the establishment of digital processes. Every activity in a company, especially in product development, is driven by data and digital processes. Not emails and documents, but data-driven process. From conceptualization to costing – data is omnipresent. Therefore, managing this data becomes crucial.

Old Habits Die Hard

While the significance of structured data management is universally acknowledged, many companies are ensnared in archaic methods of data handling, which are often inefficient.

While it is obvious to many company managers and owners that they need to operate differently the words “digital transformation” are coming from every corner, many of these companies are trapped in relatives of a traditional application-driven paradigm. This means they are following a traditional path of software selection – engineering tools (CAD) and financial tools (accounting, later MRP). This duality is triggered by the foundational principles of engineers and operators.

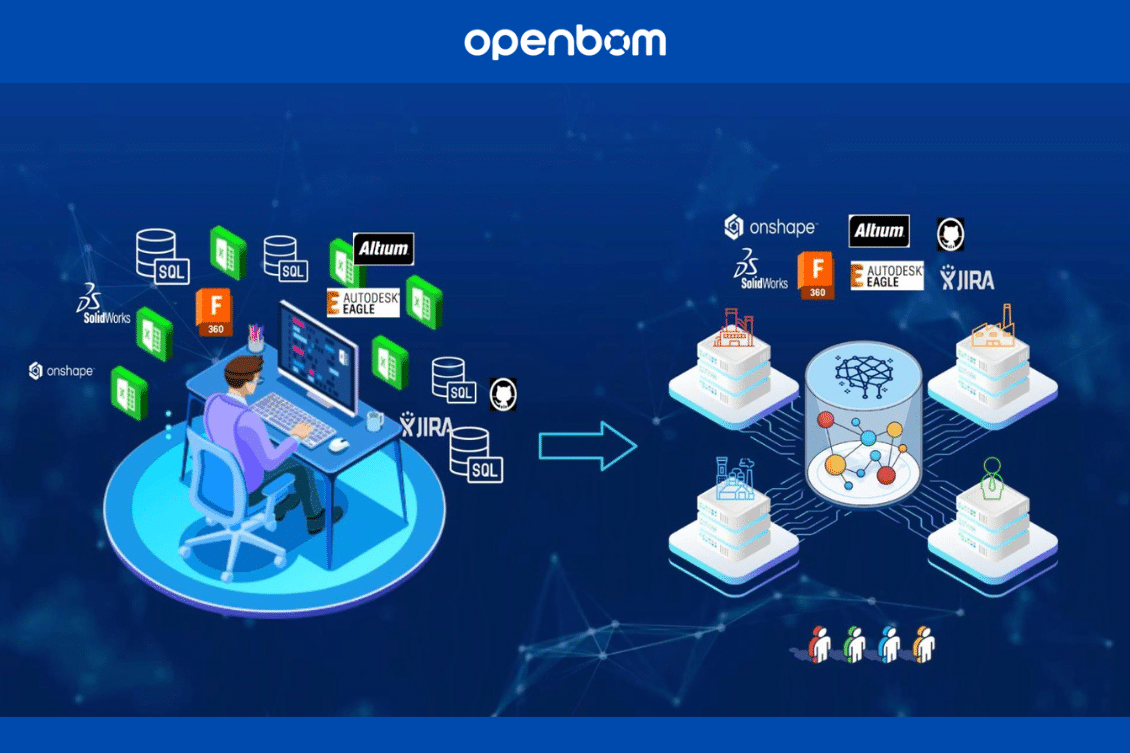

A prevalent issue is the fragmentation of data across multiple tools. Each department, from design to finance, uses specialized tools, leading to a scattered data landscape. Often, these tools are operated without a broader view of how data interplays across the organization.

The Data Transmission Dilemma

The challenge then arises – how does one facilitate data flow between these tools? More often than not, the solution is riddled with errors, resulting in a chaotic spread of files, messages, and spreadsheets. The antidote to this data chaos is simple – put data in the center. Instead of endlessly juggling between applications, companies should reorient their strategy to place ‘data at the center’.

Why is it a dilemma? Because it requires people to change. A typical engineer automatically dumps design data into an Excel file and sends it to the procurement department, which is struggling to bring this data in sync with their accounting application or even the MRP system. On the other side, engineers are often not getting any access to business tools because lack of licenses or just operational ignorance, which assumes that sending a spreadsheet is the easiest way.

How to change it and how to start thinking differently?

Put Data in the Center of Your Business

By changing a perspective on data management, a company can switch the way it operates, manages raw materials, organizes supply chains, and always controls all information about products or services. By placing product data in the center of your engineering and business operation you will ensure that all decisions in your company about material costs, customer satisfaction, demand, supply chain management, final products, cost, and every detail of the product is traceable and available to every person in the company. It helps to organize modern supply chain practices, improve efficiency, and, most importantly, find a competitive advantage in your business compared to other companies.

Here is the recipe for how to make it happen. It requires the establishment of product product-centric data architecture where all informational elements are connected and there is a continuous flow model bringing the information together.

Here are three pillars model for efficient data management for hard tech companies:

Unified Items Database: Establish a singular database, capturing all product components. This database should have a unique numbering system, enriched with exhaustive information ranging from physical characteristics to supplier data and costing.

Digital BOM: Maintain thorough records of products, detailing components used, their versions, and subsequent changes Every item must have a full set of components, structured in a way to represent all data, dependencies, and links to suppliers, contractors, specifications, cost, etc.

Seamless Data Integration: It’s pivotal to ensure seamless data extraction from all tools, be it CAD, finance, or any other tools. The focus should be on accessing data from a central point, rather than redundant copying and “syncing” data between application data points.

Conclusion

In the digital age, fragmented data is a liability. Navigating between various applications, only to access disjointed information, can cripple the efficiency and decision-making capability of hard tech companies. Centralized data repositories, encompassing every nuance from parts to supplier history, can be the very tool that pivots a company’s trajectory. After all, in the world of hard tech, data isn’t just king; it’s the entire kingdom.

REGISTER FOR FREE to check how OpenBOM can help. You can start a 14-day free trial and request an online personal demonstration.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.