Items and product structure is part of the OpenBOM core foundation. It creates an abstraction model to manage the data of any product. An item is an abstract object that can hold information about anything. It can be an off-the-shelf part, assembly, material, or anything else.

This blog post will give you an overview of items and product structure. We’ll discuss what they are, how they work, and their role in managing data using OpenBOM. After reading this post, you’ll have a better understanding of how to optimize your product structure and manage a product lifecycle.

What is an Item?

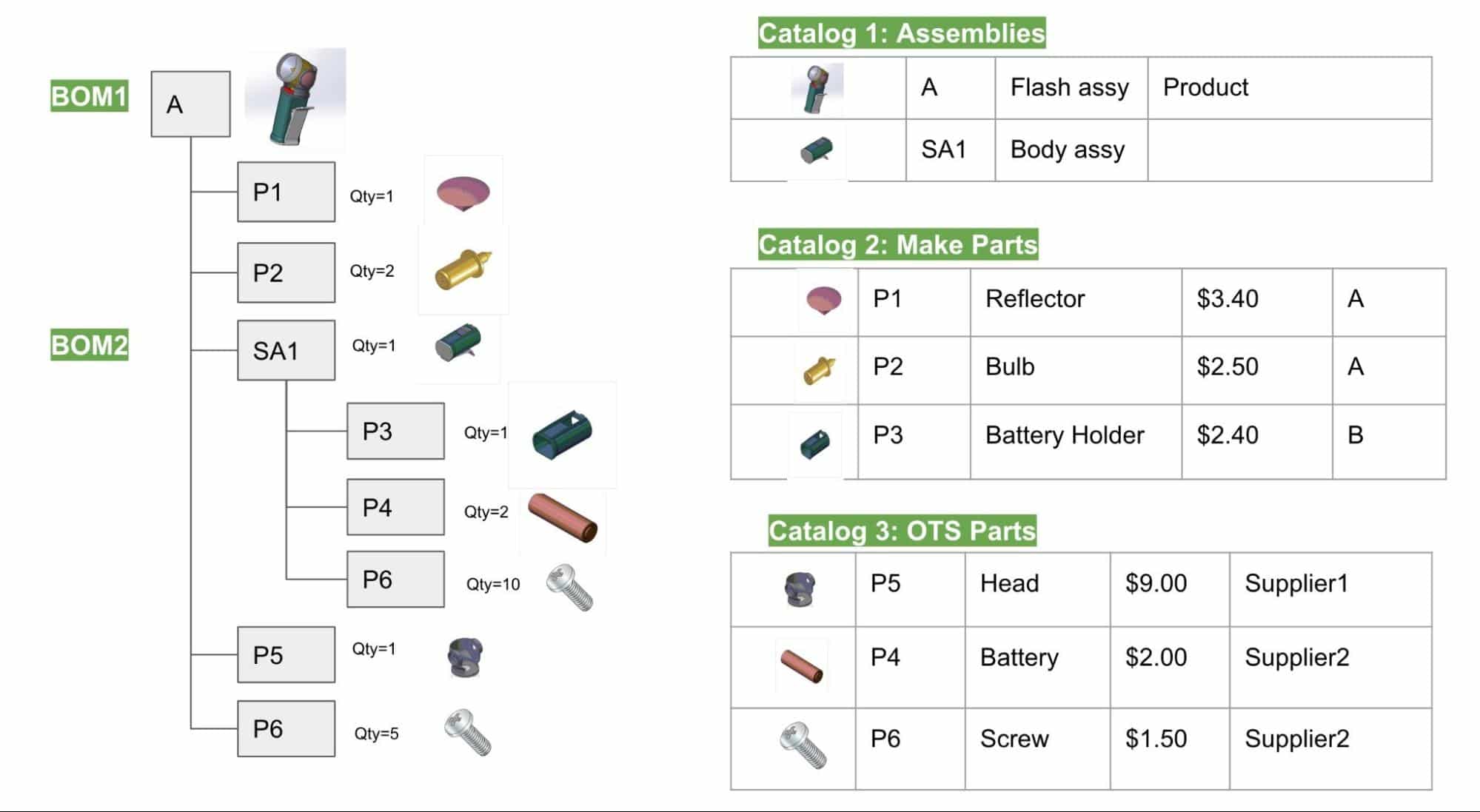

An item is any object that can be managed using OpenBOM. You can manage items using catalogs. You can define catalogs to manage different item types. Catalogs are used to store your standard items, engineering items, and products, and are reusable. Every item you use in the bill of materials (for every part or assembly/sub-assembly) must be defined in the catalog first. You can use it as a database to define your items for all BOMs. A part number is the key element of OpenBOM data management. Every record in the OpenBOM catalog is associated with a part number and it becomes a unique identifier for your parts and assemblies.

Part numbers are used in OpenBOM parent-child relationships. OpenBOM maintains the uniqueness of part numbers automatically using catalog features (see below). OpenBOM can also help you to control the uniqueness of part numbers in your organization (using the Company Part Number feature). The OpenBOM catalog provides you with a way to automatically generate part numbers using “Part Number Setup” (refer to part catalog documentation).

Item revisions are associated with the part number and OpenBOM catalogs allow you to preserve the history of changes in the catalog as well as create item revisions.

What is Product Structure?

A product structure represents a full definition of the product with all items organized hierarchically as assemblies, sub-assemblies and parts. OpenBOM is managing product structures using Bill of Materials objects. A bill of materials (BOM) is a list of the assemblies, items, and quantities needed to get a finished product. Catalog items can be reused in different BOMs, and you can add additional information to the catalog items in the BOMs, such as quantity or reference designation. OpenBOM allows you to track the history of changes automatically and create BOM revisions (to extend the information, OpenBOM stores item revisions in the catalog).

VIDEO

In the following video, you can watch a quick review of what Item and Product Structures are and how to manage them using OpenBOM.

Conclusion:

Items and Product Structures are foundational elements of the OpenBOM data model. They allow the management of product information in a granular and structured manner. OpenBOM manages Items using catalogs. You can define as many catalogs as you need and use them for different item types (mechanical, electrical, assembly, materials, labor, etc.). OpenBOM manages product structure by organizing a bill of materials that represents a list of items and is organized into a hierarchy using parent-child relationships.

Manage Items and Product structure is easy and OpenBOM gives an ultimate level of flexibility in data modeling to define any type of items, and structures and manage additional information such as the history of changes, revisions, sourcing, and many others.

REGISTER FOR FREE and start a free 14-day trial to check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.